Standing Rigging (or ‘Name That Stay’)

Published by rigworks on november 19, 2019.

Question: When your riggers talk about standing rigging, they often use terms I don’t recognize. Can you break it down for me?

From the Rigger: Let’s play ‘Name that Stay’…

Forestay (1 or HS) – The forestay, or headstay, connects the mast to the front (bow) of the boat and keeps your mast from falling aft.

- Your forestay can be full length (masthead to deck) or fractional (1/8 to 1/4 from the top of the mast to the deck).

- Inner forestays, including staysail stays, solent stays and baby stays, connect to the mast below the main forestay and to the deck aft of the main forestay. Inner forestays allow you to hoist small inner headsails and/or provide additional stability to your rig.

Backstay (2 or BS) – The backstay runs from the mast to the back of the boat (transom) and is often adjustable to control forestay tension and the shape of the sails.

- A backstay can be either continuous (direct from mast to transom) or it may split in the lower section (7) with “legs” that ‘V’ out to the edges of the transom.

- Backstays often have hydraulic or manual tensioners built into them to increase forestay tension and bend the mast, which flattens your mainsail.

- Running backstays can be removable, adjustable, and provide additional support and tuning usually on fractional rigs. They run to the outer edges of the transom and are adjusted with each tack. The windward running back is in tension and the leeward is eased so as not to interfere with the boom and sails.

- Checkstays, useful on fractional rigs with bendy masts, are attached well below the backstay and provide aft tension to the mid panels of the mast to reduce mast bend and provide stabilization to reduce the mast from pumping.

Shrouds – Shrouds support the mast from side to side. Shrouds are either continuous or discontinuous .

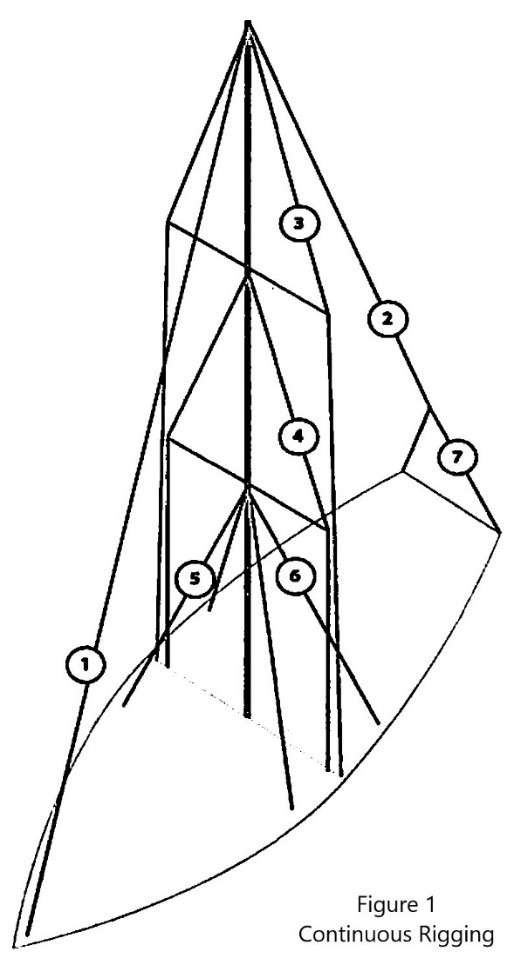

Continuous rigging, common in production sailboats, means that each shroud (except the lowers) is a continuous piece of material that connects to the mast at some point, passes through the spreaders without terminating, and continues to the deck. There may be a number of continuous shrouds on your boat ( see Figure 1 ).

- Cap shrouds (3) , sometimes called uppers, extend from masthead to the chainplates at the deck.

- Intermediate shrouds (4) extend from mid-mast panel to deck.

- Lower shrouds extend from below the spreader-base to the chainplates. Fore- (5) and Aft-Lowers (6) connect to the deck either forward or aft of the cap shroud.

Discontinuous rigging, common on high performance sailboats, is a series of shorter lengths that terminate in tip cups at each spreader. The diameter of the wire/rod can be reduced in the upper sections where loads are lighter, reducing overall weight. These independent sections are referred to as V# and D# ( see Figure 2 ). For example, V1 is the lowest vertical shroud that extends from the deck to the outer tip of the first spreader. D1 is the lowest diagonal shroud that extends from the deck to the mast at the base of the first spreader. The highest section that extends from the upper spreader to the mast head may be labeled either V# or D#.

A sailboat’s standing rigging is generally built from wire rope, rod, or occasionally a super-strong synthetic fibered rope such as Dyneema ® , carbon fiber, kevlar or PBO.

- 1×19 316 grade stainless steel Wire Rope (1 group of 19 wires, very stiff with low stretch) is standard on most sailboats. Wire rope is sized/priced by its diameter which varies from boat to boat, 3/16” through 1/2″ being the most common range.

- 1×19 Compact Strand or Dyform wire, a more expensive alternative, is used to increase strength, reduce stretch, and minimize diameter on high performance boats such as catamarans. It is also the best alternative when replacing rod with wire.

- Rod rigging offers lower stretch, longer life expectancy, and higher breaking strength than wire. Unlike wire rope, rod is defined by its breaking strength, usually ranging from -10 to -40 (approx. 10k to 40k breaking strength), rather than diameter. So, for example, we refer to 7/16” wire (diameter) vs. -10 Rod (breaking strength).

- Composite Rigging is a popular option for racing boats. It offers comparable breaking strengths to wire and rod with a significant reduction in weight and often lower stretch.

Are your eyes crossing yet? This is probably enough for now, but stay tuned for our next ‘Ask the Rigger’. We will continue this discussion with some of the fittings/connections/hardware associated with your standing rigging.

Related Posts

Ask the Rigger

Do your masthead sheaves need replacing.

Question: My halyard is binding. What’s up? From the Rigger: Most boat owners do not climb their masts regularly, but our riggers spend a lot of time up there. And they often find badly damaged Read more…

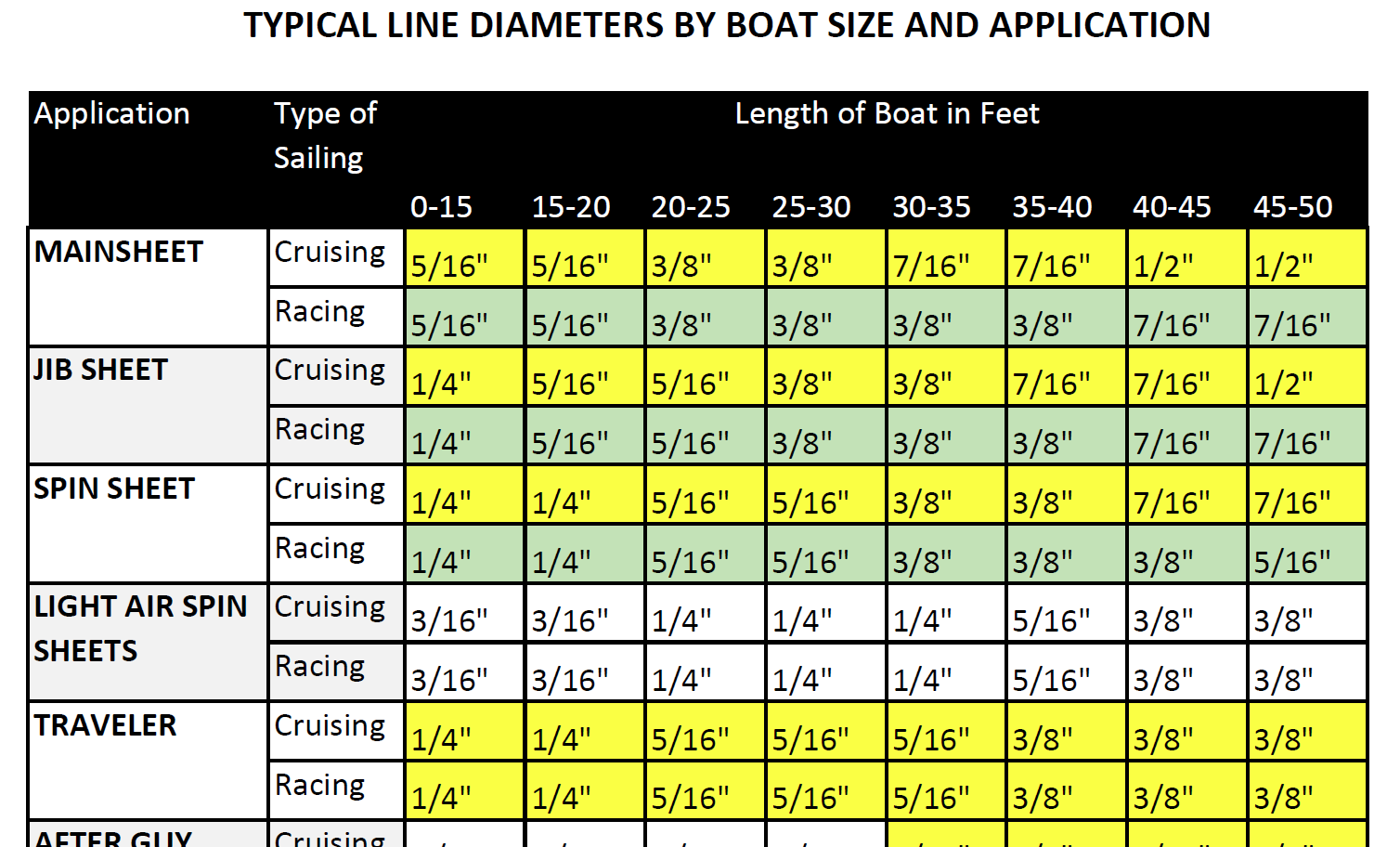

Selecting Rope – Length, Diameter, Type

Question: Do you have guidelines for selecting halyards, sheets, etc. for my sailboat? From the Rigger: First, if your old rope served its purpose but needs replacing, we recommend duplicating it as closely as possible Read more…

Spinlock Deckvest Maintenance

Question: What can I do to ensure that my Spinlock Deckvest is well-maintained and ready for the upcoming season? From the Rigger: We are so glad you asked! Deckvests need to be maintained so that Read more…

No products in the cart.

Sailing Ellidah is supported by our readers. Buying through our links may earn us an affiliate commission at no extra cost to you.

The Standing Rigging On A Sailboat Explained

The standing rigging on a sailboat is a system of stainless steel wires that holds the mast upright and supports the spars.

In this guide, I’ll explain the basics of a sailboat’s hardware and rigging, how it works, and why it is a fundamental and vital part of the vessel. We’ll look at the different parts of the rig, where they are located, and their function.

We will also peek at a couple of different types of rigs and their variations to determine their differences. In the end, I will explain some additional terms and answer some practical questions I often get asked.

But first off, it is essential to understand what standing rigging is and its purpose on a sailboat.

The purpose of the standing rigging

Like I said in the beginning, the standing rigging on a sailboat is a system of stainless steel wires that holds the mast upright and supports the spars. When sailing, the rig helps transfer wind forces from the sails to the boat’s structure. This is critical for maintaining the stability and performance of the vessel.

The rig can also consist of other materials, such as synthetic lines or steel rods, yet its purpose is the same. But more on that later.

Since the rig supports the mast, you’ll need to ensure that it is always in appropriate condition before taking your boat out to sea. Let me give you an example from a recent experience.

Dismasting horrors

I had a company inspect the entire rig on my sailboat while preparing for an Atlantic crossing. The rigger didn’t find any issues, but I decided to replace the rig anyway because of its unknown age. I wanted to do the job myself so I could learn how it is done correctly.

Not long after, we left Gibraltar and sailed through rough weather for eight days before arriving in Las Palmas. We were safe and sound and didn’t experience any issues. Unfortunately, several other boats arriving before us had suffered rig failures. They lost their masts and sails—a sorrowful sight but also a reminder of how vital the rigging is on a sailboat.

The most common types of rigging on a sailboat

The most commonly used rig type on modern sailing boats is the fore-and-aft Bermuda Sloop rig with one mast and just one headsail. Closely follows the Cutter rig and the Ketch rig. They all have a relatively simple rigging layout. Still, there are several variations and differences in how they are set up.

A sloop has a single mast, and the Ketch has one main mast and an additional shorter mizzen mast further aft. A Cutter rig is similar to the Bermuda Sloop with an additional cutter forestay, allowing it to fly two overlapping headsails.

You can learn more about the differences and the different types of sails they use in this guide. For now, we’ll focus on the Bermuda rig.

The difference between standing rigging and running rigging

Sometimes things can get confusing as some of our nautical terms are used for multiple items depending on the context. Let me clarify just briefly:

The rig or rigging on a sailboat is a common term for two parts:

- The standing rigging consists of wires supporting the mast on a sailboat and reinforcing the spars from the force of the sails when sailing.

- The running rigging consists of the halyards, sheets, and lines we use to hoist, lower, operate, and control the sails on a sailboat.

Check out my guide on running rigging here !

The difference between a fractional and a masthead rig

A Bermuda rig is split into two groups. The Masthead rig and the Fractional rig.

The Masthead rig has a forestay running from the bow to the top of the mast, and the spreaders point 90 degrees to the sides. A boat with a masthead rig typically carries a bigger overlapping headsail ( Genoa) and a smaller mainsail. Very typical on the Sloop, Ketch, and Cutter rigs.

A Fractional rig has forestays running from the bow to 1/4 – 1/8 from the top of the mast, and the spreaders are swept backward. A boat with a fractional rig also has the mast farther forward than a masthead rig, a bigger mainsail, and a smaller headsail, usually a Jib. Very typical on more performance-oriented sailboats.

There are exceptions in regards to the type of headsail, though. Many performance cruisers use a Genoa instead of a Jib , making the difference smaller.

Some people also fit an inner forestay, or a babystay, to allow flying a smaller staysail.

Explaining the parts and hardware of the standing rigging

The rigging on a sailing vessel relies on stays and shrouds in addition to many hardware parts to secure the mast properly. And we also have nautical terms for each of them. Since a system relies on every aspect of it to be in equally good condition, we want to familiarize ourselves with each part and understand its function.

Forestay and Backstay

The forestay is a wire that runs from the bow to the top of the mast. Some boats, like the Cutter rig, can have several additional inner forestays in different configurations.

The backstay is the wire that runs from the back of the boat to the top of the mast. Backstays have a tensioner, often hydraulic, to increase the tension when sailing upwind. Some rigs, like the Cutter, have running backstays and sometimes checkstays or runners, to support the rig.

The primary purpose of the forestay and backstay is to prevent the mast from moving fore and aft. The tensioner on the backstay also allows us to trim and tune the rig to get a better shape of the sails.

The shrouds are the wires or lines used on modern sailboats and yachts to support the mast from sideways motion.

There are usually four shrouds on each side of the vessel. They are connected to the side of the mast and run down to turnbuckles attached through toggles to the chainplates bolted on the deck.

- Cap shrouds run from the top of the mast to the deck, passing through the tips of the upper spreaders.

- Intermediate shrouds run from the lower part of the mast to the deck, passing through the lower set of spreaders.

- Lower shrouds are connected to the mast under the first spreader and run down to the deck – one fore and one aft on each side of the boat.

This configuration is called continuous rigging. We won’t go into the discontinuous rigging used on bigger boats in this guide, but if you are interested, you can read more about it here .

Shroud materials

Shrouds are usually made of 1 x 19 stainless steel wire. These wires are strong and relatively easy to install but are prone to stretch and corrosion to a certain degree. Another option is using stainless steel rods.

Rod rigging

Rod rigging has a stretch coefficient lower than wire but is more expensive and can be intricate to install. Alternatively, synthetic rigging is becoming more popular as it weighs less than wire and rods.

Synthetic rigging

Fibers like Dyneema and other aramids are lightweight and provide ultra-high tensile strength. However, they are expensive and much more vulnerable to chafing and UV damage than other options. In my opinion, they are best suited for racing and regatta-oriented sailboats.

Wire rigging

I recommend sticking to the classic 316-graded stainless steel wire rigging for cruising sailboats. It is also the most reasonable of the options. If you find yourself in trouble far from home, you are more likely to find replacement wire than another complex rigging type.

Relevant terms on sailboat rigging and hardware

The spreaders are the fins or wings that space the shrouds away from the mast. Most sailboats have at least one set, but some also have two or three. Once a vessel has more than three pairs of spreaders, we are probably talking about a big sailing yacht.

A turnbuckle is the fitting that connects the shrouds to the toggle and chainplate on the deck. These are adjustable, allowing you to tension the rig.

A chainplate is a metal plate bolted to a strong point on the deck or side of the hull. It is usually reinforced with a backing plate underneath to withstand the tension from the shrouds.

The term mast head should be distinct from the term masthead rigging. Out of context, the mast head is the top of the mast.

A toggle is a hardware fitting to connect the turnbuckles on the shrouds and the chainplate.

How tight should the standing rigging be?

It is essential to periodically check the tension of the standing rigging and make adjustments to ensure it is appropriately set. If the rig is too loose, it allows the mast to sway excessively, making the boat perform poorly.

You also risk applying a snatch load during a tack or a gybe which can damage the rig. On the other hand, if the standing rigging is too tight, it can strain the rig and the hull and lead to structural failure.

The standing rigging should be tightened enough to prevent the mast from bending sideways under any point of sail. If you can move the mast by pulling the cap shrouds by hand, the rigging is too loose and should be tensioned. Once the cap shrouds are tightened, follow up with the intermediates and finish with the lower shrouds. It is critical to tension the rig evenly on both sides.

The next you want to do is to take the boat out for a trip. Ensure that the mast isn’t bending over to the leeward side when you are sailing. A little movement in the leeward shrouds is normal, but they shouldn’t swing around. If the mast bends to the leeward side under load, the windward shrouds need to be tightened. Check the shrouds while sailing on both starboard and port tack.

Once the mast is in a column at any point of sail, your rigging should be tight and ready for action.

If you feel uncomfortable adjusting your rig, get a professional rigger to inspect and reset it.

How often should the standing rigging be replaced on a sailboat?

I asked the rigger who produced my new rig for Ellidah about how long I could expect my new rig to last, and he replied with the following:

The standing rigging should be replaced after 10 – 15 years, depending on how hard and often the boat has sailed. If it is well maintained and the vessel has sailed conservatively, it will probably last more than 20 years. However, corrosion or cracked strands indicate that the rig or parts are due for replacement regardless of age.

If you plan on doing extended offshore sailing and don’t know the age of your rig, I recommend replacing it even if it looks fine. This can be done without removing the mast from the boat while it is still in the water.

How much does it cost to replace the standing rigging?

The cost of replacing the standing rigging will vary greatly depending on the size of your boat and the location you get the job done. For my 41 feet sloop, I did most of the installation myself and paid approximately $4700 for the entire rig replacement.

Can Dyneema be used for standing rigging?

Dyneema is a durable synthetic fiber that can be used for standing rigging. Its low weight, and high tensile strength makes it especially popular amongst racers. Many cruisers also carry Dyneema onboard as spare parts for failing rigging.

How long does dyneema standing rigging last?

Dyneema rigging can outlast wire rigging if it doesn’t chafe on anything sharp. There are reports of Dyneema rigging lasting as long as 15 years, but manufacturers like Colligo claim their PVC shrink-wrapped lines should last 8 to 10 years. You can read more here .

Final words

Congratulations! By now, you should have a much better understanding of standing rigging on a sailboat. We’ve covered its purpose and its importance for performance and safety. While many types of rigs and variations exist, the hardware and concepts are often similar. Now it’s time to put your newfound knowledge into practice and set sail!

Or, if you’re not ready just yet, I recommend heading over to my following guide to learn more about running rigging on a sailboat.

Sharing is caring!

Skipper, Electrician and ROV Pilot

Robin is the founder and owner of Sailing Ellidah and has been living on his sailboat since 2019. He is currently on a journey to sail around the world and is passionate about writing his story and helpful content to inspire others who share his interest in sailing.

Very well written. Common sense layout with just enough photos and sketches. I enjoyed reading this article.

Thank you for the kind words.

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

What is a Sailboat Stay?

Last Updated by

Daniel Wade

June 15, 2022

A sailboat stay is a cable or line that supports the mast. Stays bear a significant portion of the mast load.

Stays are a significant part of a sailboat's standing rigging, and they're essential for safe sailing. Stays support the mast and bear the stress of the wind and the sails. Losing a stay is a serious problem at sea, which is why it's essential to keep your stays in good condition.

Table of contents

How to Identify Sailboat Stays

Sailboat stays connected to the top of the mast to the deck of the sailboat. Stays stabilize the mast in the forward and aft directions. Stays are typically mounted to the very front of the bow and the rearmost part of the stern.

Sailboat Forestay

The forestay connects the top of the mast to the bow of the boat. The forestay also serves an additional purpose—the jib sail luff mounts to the forestay. In fact, the jib is hoisted up and down the forestay as if it were a mast.

Boats equipped with roller furlings utilize spindles at the top and base of the forestay. The spindles rotate to furl and unfurl the jib. Roller furlings maintain the structural integrity of a standard forestay.

Sailboat Backstay

Backstays aren't as multifunctional as forestays. The backstay runs from the top of the mast (opposite the forestay) to the stern of the sailing vessel, and it balances the force exerted by the forestay. Together, the forestay and the backstay keep the mast upright under load.

Sailboat Stay vs. Shroud

Stays and shrouds are often confused, as they essentially do the same thing (just in different places). Stays are only located on the bow and stern of the vessel—that's fore and aft. Shrouds run from the port and starboard side of the hull or deck to the top of the mast.

Best Sailboat Stay Materials

Traditional sailboat stays were made of rope and organic line. These materials worked fine for thousands of years, and they still do today. However, rope has limitations that modern sailboat stays don't.

For one, traditional rope is organic and prone to decay. It also stretches, which can throw off the balance of the mast and cause serious problems. Other materials, such as stainless steel, are more ideal for the modern world.

Most modern fiberglass sailboats use stainless steel stays. Stainless stays are made of strong woven stainless steel cable, which resists corrosion and stress. Stainless cables are also easy to adjust.

Why are Stays Important?

Stays keep the mast from collapsing. Typical sailboats have lightweight hollow aluminum masts. Alone, these thin towering poles could never hope to withstand the stress of a fully-deployed sail plan. More often than not, unstayed masts of any material fail rapidly under sail.

When properly adjusted, stays transfer the force of the wind from the thin and fragile mast to the deck or the hull. They distribute the power of the wind over a wider area and onto materials that can handle it. The mast alone simply provides a tall place to attach the head of the sail, along with a bit of structural support.

Sailboat Chain Plates

Sailboat stays need a strong mounting point to handle the immense forces they endure. Stays mount to the deck on chainplates, which further distribute force to support the load.

Chainplates are heavy steel mounting brackets that typically come with two pieces. One plate mounts on top of the deck and connects to the stay. The other plate mounts on the underside of the deck directly beneath the top plate, and the two-bolt together.

Mast Stay Mounting

Stays mount to the mast in several ways depending on the vessel and the mast material. On aluminum masts, stays often mount to a type of chain plate called a "tang." A tang consists of a bracket and a hole for a connecting link. Aluminum masts also use simple U-bolts for mounting stays.

Wooden masts don't hold up to traditional brackets as well as aluminum. A simple u-bolt or flat bolt-on bracket might tear right out. As a result, wooden masts often use special collars with mounting rings on each side. These collars are typically made of brass or stainless steel.

Sailboat Stays on Common Rigs

Stays on a Bermuda-rigged sailboat are critical. Bermuda rigs use a triangular mainsail . Triangular sails spread their sail area vertically, which necessitates a tall mast.

Bermuda rig masts are often thin, hollow, and made of lightweight material like aluminum to avoid making the boat top-heavy. As a result, stays, and shrouds are of critical importance on a Bermuda rig.

Traditional gaff-rigged sail plans don't suffer as much from this issue. Gaff rigs use a four-pointed mainsail. This sail has a peak that's taller than the head and sometimes taller than the mast.

Gaff-rigged cutters, sloops, schooners, and other vessels use comparatively shorter and heavier masts, which are less likely to collapse under stress. These vessels still need stays and shrouds, but their stronger masts tend to be more forgiving in unlucky situations.

How to Adjust Sailboat Stays

Sailboat stays and shrouds must be checked and adjusted from time to time, as even the strongest stainless steel cable stretches out of spec. Sailboats must be in the water when adjusting stays. Here's the best way to keep the proper tension on your stays.

Loosen the Stays

Start by loosening the forestay and backstay. Try to do this evenly, as it'll reduce the stress on the mast. Locate the turnbuckles and loosen them carefully.

Match the Turnbuckle Threads

Before tightening the turnbuckle again, make sure the top and bottom threads protrude the same amount. This reduces the chance of failure and allows you to equally adjust the stay in both directions.

Center the Mast

Make sure the mast is centered on its own. If it's not, carefully take up the slack in the direction you want it to go. Once the mast is lined up properly, it's time to tighten both turnbuckles again.

Tighten the Turnbuckles

Tighten the turnbuckles as evenly as possible. Periodically monitor the direction of the mast and make sure you aren't pulling it too far in a single direction.

Determine the Proper Stay Pressure

This step is particularly important, as stays must be tightened within a specific pressure range to work properly. The tension on a sailboat stay ranges from a few hundred pounds to several tons, so it's essential to determine the correct number ahead of time. Use an adjuster to monitor the tension.

What to Do if you Lose a Stay

Thankfully, catastrophic stay and shroud failures are relatively rare at sea. Losing a mast stay is among the worst things that can happen on a sailboat, especially when far from shore.

The stay itself can snap with tremendous force and cause injury or damage. If it doesn't hurt anyone, it'll certainly put the mast at risk of collapsing. In fact, if you lose a stay, your mast will probably collapse if stressed.

However, many sailors who lost a forestay or backstay managed to keep their mast in one piece using a halyard. In the absence of a replacement stay, any strong rope can offer some level of protection against dismasting .

How to Prevent a Stay Failure

Maintenance and prevention is the best way to avoid a catastrophic stay failure. Generally speaking, the complete failure of a stay usually happens in hazardous weather conditions or when there's something seriously wrong with the boat.

Stays sometimes fail because of manufacturing defects, but it's often due to improper tension, stripped threads, or aging cable that hasn't been replaced. Regular maintenance can prevent most of these issues.

Check the chainplates regularly, as they can corrode quietly with little warning. The deck below the chainplates should also be inspected for signs of rot or water leakage.

When to Replace Standing Rigging

Replace your stays and shrouds at least once every ten years, and don't hesitate to do it sooner if you see any signs of corrosion or fraying. Having reliable standing rigging is always worth the added expense.

Choosing a high-quality stay cable is essential, as installing substandard stays is akin to playing with fire. Your boat will thank you for it, and it'll be easier to tune your stays for maximum performance.

Related Articles

I've personally had thousands of questions about sailing and sailboats over the years. As I learn and experience sailing, and the community, I share the answers that work and make sense to me, here on Life of Sailing.

by this author

Sailboat Parts

Learn About Sailboats

Most Recent

What Does "Sailing By The Lee" Mean?

October 3, 2023

The Best Sailing Schools And Programs: Reviews & Ratings

September 26, 2023

Important Legal Info

Lifeofsailing.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon. This site also participates in other affiliate programs and is compensated for referring traffic and business to these companies.

Similar Posts

Affordable Sailboats You Can Build at Home

September 13, 2023

Best Small Sailboat Ornaments

September 12, 2023

Discover the Magic of Hydrofoil Sailboats

December 11, 2023

Popular Posts

Best Liveaboard Catamaran Sailboats

December 28, 2023

Can a Novice Sail Around the World?

Elizabeth O'Malley

4 Best Electric Outboard Motors

How Long Did It Take The Vikings To Sail To England?

10 Best Sailboat Brands (And Why)

December 20, 2023

7 Best Places To Liveaboard A Sailboat

Get the best sailing content.

Top Rated Posts

Lifeofsailing.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon. This site also participates in other affiliate programs and is compensated for referring traffic and business to these companies. (866) 342-SAIL

© 2024 Life of Sailing Email: [email protected] Address: 11816 Inwood Rd #3024 Dallas, TX 75244 Disclaimer Privacy Policy

Sailboat Shroud: Everything You Need to Know

by Emma Sullivan | Jul 27, 2023 | Sailboat Maintenance

Short answer sailboat shroud:

A sailboat shroud is a part of the standing rigging system that supports the mast and helps maintain its stability. These load-bearing wires or cables are attached to the sides of the boat and provide crucial support for the mast by counteracting lateral forces.

Understanding the Importance of a Sailboat Shroud: A Comprehensive Guide

The sailboat shroud: an often overlooked yet indispensable component of any sailing vessel. While its name may sound somewhat unfamiliar to the uninitiated, its significance in ensuring a safe and successful sailing experience cannot be overstated. In this comprehensive guide, we will delve into the critical role that sailboat shrouds play, unraveling their importance to both the functionality and safety of your beloved watercraft.

Firstly, let’s demystify what exactly a sailboat shroud entails. The term “shroud” refers to a collection of wires (usually made from stainless steel) or synthetic fibers that are strategically positioned on either side of the mast, providing structural support to maintain its stability during navigation. These rigging components act as tension-bearing elements that transfer various forces between the mast and the hull of the sailboat, ensuring its structural integrity is maintained under varying wind conditions.

One might wonder: why are these shrouds so important? Well, at their core, they serve primarily to counteract lateral forces acting upon the mast while also assisting in maintaining its vertical alignment. When properly tensioned, they prevent excessive sideways movement known as “mast rake,” thereby allowing for improved directional control and optimized sailing performance. In essence, sailboat shrouds directly contribute to maximizing your vessel’s efficiency by minimizing unnecessary energy loss due to excess mast movement.

Beyond optimizing performance, however, shrouds are instrumental in guaranteeing your safety whilst out on the open water. By firmly securing the mast in place through their tensioned presence, they help distribute loads evenly throughout the sailboat’s structure – preventing it from collapsing or compromising stability under heavy gusts or turbulent conditions. This aspect is particularly crucial during rough weather conditions or when encountering strong currents where failing to account for these external factors could potentially lead to catastrophic consequences.

Moreover – and here comes one of their most valuable features – well-maintained sailboat shrouds can actually save you money by keeping the rest of your rigging in good condition. When appropriately tensioned, they actively contribute to reducing stress on other interconnected components such as spreaders, stays, and halyards, thus minimizing wear and tear caused by excessive movement or strain. By employing sailboat shrouds effectively, you’ll be able to avoid unnecessary repair costs and extend the lifespan of your entire rigging system.

Understanding the significance of proper sailboat shroud maintenance is equally essential to fully grasp their overall importance. Regular inspection for signs of wear or corrosion should form part of routine boat maintenance. Any damaged wires or weak points must be promptly replaced to maintain optimal functionality and prevent potential accidents. Additionally, adjusting the shroud tension periodically – in harmony with manufacturer recommendations and prevailing weather conditions – will ensure consistent performance over time.

In conclusion, a sailboat shroud may be just one part of your vessel’s intricate rigging system, but its contribution cannot be understated. From optimizing sailing efficiency through improved handling and control to ensuring safety during challenging conditions, these unassuming yet vital components play an integral role in any sailor’s experience. Acknowledging their worth and prioritizing proper maintenance will undoubtedly lead to smoother journeys on the open seas while extending the longevity of your prized sailboat investment.

How to Properly Install a Sailboat Shroud: Step-by-Step Instructions

Title: Rigging Your Sailboat with Finesse: A Step-by-Step Guide to Installing Shrouds

Introduction: Setting up the shrouds on your sailboat is an essential part of rigging. These vital components provide support for the mast and ensure stability while sailing. While many sailors rely on professionals for this task, understanding how to properly install a sailboat shroud can be incredibly empowering and save you money. In this step-by-step guide, we will walk you through the process with detailed professional instructions, spiced with a touch of wit and cleverness.

Step 1: Gather Your Tools – Preparation is Key Before you get started, arm yourself with the necessary tools: – Wrench or shroud tension gauge – Wire cutters – Cotter pins or stainless steel stoppers – Tape measure

Step 2: Measure Twice, Cut Once – Determining Shroud Lengths Measurements are crucial when it comes to installing shrouds accurately. Starting from each attachment point (chainplate or turnbuckle), stretch a tape measure upward toward your masthead. Make sure the measurements are precise, accounting for any additional hardware like spreader ends or mast tangs that may affect length requirements. Repeat this process for every shroud.

Step 3: Remove Old Shrouds – Out with the Old! If you’re working on an existing rigging setup, start by removing any old shrouds using wire cutters to clip off their bottom parts — near chainplates or turnbuckles.

Step 4: Preparing New Shrouds – Who Says Rework Isn’t Fun? Now that your old shrouds have hit the deck (pun intended!), it’s time to prepare new ones. When choosing replacement wire, opt for high-quality marine-grade stainless steel cables as they offer excellent corrosion resistance and longevity.

Cut your newly acquired cables according to the measurement gathered in Step 2. Remember to leave a little extra length for fine-tuning and adjustments during installation. Once cut, use wire cutters to fray the ends slightly. This process will aid in affixing fittings later on.

Step 5: Attaching the Bottom Ends – Keep Calm and Connect On! Starting with one side of your sailboat, connect the bottom end of each shroud cable to its respective chainplate using cotter pins or stainless steel stoppers. Ensure that you exert tension by pulling the shrouds downward while inserting and securing these fasteners. Double-check for any twisting or misalignment.

Step 6: Securing the Top Ends – Reaching New Heights! Now it’s time to ascend your mast—well, figuratively speaking! Attach each shroud’s top end to their corresponding turnbuckle, ensuring they’re oriented correctly without any twists or kinks. – Pro Tip: Orienting turnbuckles with open slots facing opposite directions makes tuning easier in future adjustments.

Step 7: Balancing Act – Find Your Sailboat’s Equilibrium Begin tightening the turnbuckles evenly on both sides of your mast while keeping an eye on their lengths. Use either a wrench or a shroud tension gauge to ensure consistent tension across all shrouds. Establish good baseline stiffness without excess rigidity, allowing flexibility required for proper sailing dynamics.

Step 8: The Final Touches – Safety First! Once satisfied with your tension setup and balance, secure each turnbuckle to avoid accidental untwisting under pressure. Cotter pins can be used here as well if they serve as an extra peace-of-mind measure against tampering.

Conclusion: By mastering how to properly install sailboat shrouds through our step-by-step guide packed with professional instructions and a sprinkle of wit, you’ve gained valuable knowledge in maintaining your vessel’s rigging setup independently. Rigging becomes an enjoyable journey when accomplished with confidence, and remember: those who sail their own shrouds are the captains of their fate on the open sea!

Common FAQs About Sailboat Shrouds Answered

Title: Unraveling the Mysteries of Sailboat Shrouds: Answering Common FAQs

Introduction: Sailing enthusiasts, both seasoned and beginners alike, often find themselves bombarded with questions about various aspects of their beloved watercraft. One such area that constantly generates curiosity is sailboat shrouds. These integral components play a crucial role in maintaining stability and safety while out on the open waters. Today, we aim to demystify these enigmatic structures by answering some frequently asked questions about sailboat shrouds.

1. What are sailboat shrouds? Sailboat shrouds are a vital part of a sailing vessel’s standing rigging system, consisting of sturdy wires or cables that support the mast from the sides. They provide lateral stability for the mast, ensuring it stays upright even under strong winds or rough seas.

2. How do sailboat shrouds work? When properly tensioned and adjusted, sailboat shrouds counteract the force exerted by the sails on the mast, preventing excessive bending or swaying. By distributing this load evenly across multiple points on either side of the mast, they effectively keep it centered and help maintain optimal performance during sailing.

3. What materials are sailboat shrouds made of? Traditionally, sailboat shrouds were constructed using stainless steel wire ropes due to their exceptional strength, durability, and resistance to corrosion in marine environments. However, modern advancements have also introduced alternatives like Dyneema®, a high-performance synthetic fiber known for its remarkable strength-to-weight ratio.

4. How often should I inspect my sailboat shrouds? Regular inspections of your sailboat’s standing rigging are essential for ensuring safety at sea. We recommend conducting thorough inspections before each sailing season and after any significant weather event or prolonged period of disuse. Typically, closely examine key areas such as fittings, turnbuckles, tangs (attachment points), and wires for signs of wear, cracks, corrosion, or loose connections.

5. Can I replace sailboat shrouds myself? While some experienced sailors may tackle minor maintenance tasks on their own, replacing sailboat shrouds is a job best left to professionals. The process involves carefully adjusting tension levels, ensuring proper alignment, and verifying that all components are compatible and correctly installed. Expert riggers possess the necessary knowledge and specialized tools to carry out these intricate procedures safely and efficiently.

6. Are there different types of sailboat shrouds? Yes, there are various configurations of sailboat shrouds tailored to specific sailing requirements. Common designs include single lower shrouds (found on smaller boats), double lower shrouds (enhanced stability for larger vessels), cap shrouds (supporting the mast from the top), and intermediate or diamond stays (adding lateral support). Consulting with a professional rigger can help determine the suitable setup for your specific sailboat.

7. How do I know if my sailboat shroud needs replacement? Several indicators might suggest it’s time to consider replacing your sailboat shroud. These include visible signs of damage such as broken wires or fatigue-induced cracking, excessive corrosion, reduced tension capacity due to stretched wires, noticeable misalignment when compared to other rigging components, or simply reaching its recommended lifespan as specified by the manufacturer.

Conclusion: Sailboat shrouds may seem like a complex subject at first glance but understanding their purpose and knowing how to properly maintain them ensures safer and more enjoyable sailing experiences. By addressing some common FAQs about these essential rigging elements, we hope to have shed light on their significance in keeping your vessel steady while conquering the magnificent seas ahead. So set your course confidently knowing that your trusty sailboat shrouds have got you covered!

The Role of a Sailboat Shroud in Ensuring Safety at Sea: Explained

Sailing is an exhilarating experience that combines the beauty of nature with the thrill of adventure. It allows us to disconnect from the chaos of our daily lives and immerse ourselves in the vastness of the open sea. However, amidst all this excitement, it is crucial to prioritize safety above all else. One vital component that plays a significant role in ensuring a safe sailing journey is the sailboat shroud.

Now, you might be wondering, what exactly is a sailboat shroud? Well, let’s dive into its importance and how it guarantees our safety while sailing.

At its core, a sailboat shroud refers to a series of tensioned cables or wires that support the mast on a sailing vessel. It acts as an essential connective element between the mast and the deck, providing stability and integrity to the entire structure. In simple terms, without sturdy sailboat shrouds, your mast would be prone to wobbling or even collapsing entirely – definitely not something you want in the middle of your oceanic voyage!

So, why are sailboat shrouds so crucial for safety? Let’s take a closer look at their key functions:

1. Stability: Imagine you’re steering your sleek yacht through choppy waters with strong winds gusting against your sails. Without reliable sailboat shrouds to support your mast, your vessel could easily lose balance and capsize – turning your exciting adventure into a dangerous nightmare. The primary function of these shrouds is to provide lateral stability by counteracting excessive sideways forces acting on the mast.

2. Structural Integrity: A sailboat shroud ensures that all elements comprising your boat’s rigging work together harmoniously. By distributing load evenly across various points on the hull and deck fittings, it prevents concentrated stress on any particular area – reducing the risk of structural failures such as cracked hulls or bent masts.

3. Control and Comfort: Sailing is about harnessing the power of wind to navigate your craft efficiently. Sailboat shrouds play a vital role in achieving this balance by allowing you to trim your sails effectively. By adjusting the tension in these rigging components, sailors can optimize their boat’s performance, maintaining a stable course and comfortable sailing experience even in rough conditions.

4. Prevention of Catastrophic Failures: In the worst-case scenario, where extreme conditions or unforeseen events create immense stress on your mast, sailboat shrouds act as a safety net, preventing catastrophic failures. They absorb excessive forces and provide a buffer zone for potential damage – giving you precious time to react before things take a turn for the worse.

However, bear in mind that sailboat shrouds aren’t invincible superheroes; they require regular inspection and maintenance to ensure their effectiveness. Over time, exposure to saltwater environments and constant tension can cause wear and tear on these critical components. Routine checks for signs of corrosion, fraying wires, or damaged fittings are essential practices that should never be neglected.

In conclusion, sailboat shrouds are not only essential but invaluable when it comes to ensuring safety at sea. From providing stability and structural integrity to enabling control and preventing catastrophic failures, these unassuming wires play an instrumental role in our nautical adventures.

So next time you find yourself aboard an elegant sailboat venturing into the vast blue unknown, remember to thank those trusty sailboat shrouds silently working behind the scenes – safeguarding your journey amidst windswept waves while allowing you revel in nature’s embrace with peace of mind knowing you’re well protected!

Expert Tips for Maintaining and Inspecting Your Sailboat Shrouds

Title: Mastering the Art of Sailboat Shroud Maintenance and Inspection: Expert Tips Unveiled

Introduction: Embarking on a sailing adventure is a thrilling experience, but it’s crucial to ensure that your vessel is maintained in top-notch condition. Among the many critical components of your sailboat, the shrouds play a paramount role in supporting your mast, preserving stability, and guaranteeing safety. In this blog post, we aim to equip you with expert tips that will assist you in maintaining and inspecting your sailboat shrouds effectively. Let’s dive into the world of sailboat care!

1. Brush Up Your Knowledge: Before delving into maintenance techniques, it is essential to understand what sailboat shrouds are and how they function. Shrouds are stainless steel cables or rods that run from various parts of the mast down to the hull. They prevent excessive bending and swaying of the mast when under high wind-pressure conditions or while under sail. Being aware of their purpose will help you comprehend why their proper upkeep is indispensable.

2. Routine Inspections are Vital: Begin by conducting frequent inspections around every two to three months or whenever you return from extended voyages. Look out for signs of rust, elongation, fraying, or corrosion on both ends (connectors) as well as along its length using a magnifying glass if necessary. Any indication of wear or damage should not be taken lightly; instead, take immediate action.

3. Check Tensions Regularly: Maintaining optimum tension on your shrouds promotes overall boat performance and reduces unnecessary strain on other rigging elements such as stays and spreaders – enhancing stability during sailing trips.

4. Replace Worn Parts Promptly: As soon as you identify any deformities, such as frayed strands or localized corrosion spots on your shrouds during an inspection, it is paramount to replace them promptly with new ones that meet the manufacturer’s specifications. Ignoring these signs could lead to catastrophic failures at sea, jeopardizing both your safety and that of your beloved sailboat.

5. Don’t Overlook Turnbuckles: Pay special attention to the turnbuckles that adjust the tension in your shrouds, as they are often vulnerable to corrosion due to their exposed location. Applying a high-quality, marine-grade lubricant regularly will keep them functioning smoothly and preserve their longevity.

6. Tidy Up Your Shroud Rigging: Over time, accumulated dirt, salt residue, or bird droppings can affect the structural integrity of your shrouds. Use mild soapy water and a non-abrasive brush to clean them gently. Avoid harsh chemical cleaners as they might damage the stainless steel surface. Remember, cleanliness goes hand in hand with durability!

7. Consult Professionals for Detailed Inspections: While regular inspections are indispensable, it is still prudent to consult professional riggers or sailing experts for periodic thorough assessments of your sailboat’s rigging system – including sailboat shrouds. Their experience enables them to detect issues not apparent during routine checks and provide expert advice on maintenance practices tailored specifically to your vessel.

Conclusion: Maintaining and inspecting your sailboat shrouds shouldn’t be taken lightly; they form an integral part of keeping you safe during all sailing endeavors. By following these expert tips diligently, conducting routine inspections, addressing issues promptly, and seeking professional assistance when necessary—you’ll ensure optimal performance from the essential components that embellish your prideful sailboat! Set sail confidently knowing that you’ve mastered the art of maintaining and inspecting your sailboat shrouds like a true professional!

Upgrading Your Sailboat Shrouds: Key Considerations for Performance Enhancement

When it comes to upgrading your sailboat shrouds, there are several key considerations that can enhance your vessel’s overall performance. Shrouds play a crucial role in supporting the mast and maintaining its stability, so it’s important to carefully evaluate all aspects before making any changes. In this blog post, we will delve into the intricacies of upgrading sailboat shrouds, discussing various factors to take into account and guiding you towards an informed decision.

Before embarking on this upgrade journey, it is imperative to assess the current condition of your sailboat shrouds. Inspect them thoroughly for signs of wear and tear such as rust, fraying wires, or any obvious structural weaknesses. If you notice any concerning issues, it may be wise to consult with a professional rigging expert or rigger who can provide an objective assessment.

One key consideration when upgrading your shrouds is the material from which they are made. Traditionally, stainless steel has been the go-to choice due to its durability and strength. However, advancements in textile technology have paved the way for alternative materials such as Dyneema or carbon fiber composites which offer substantial weight savings without compromising strength.

Choosing the right size and diameter for your upgraded shrouds is another vital aspect to consider. The load-bearing capacity of the mast and rigging system should be evaluated in order to determine the appropriate size that can effectively withstand anticipated stresses during sailing maneuvers. Consulting with a rigging specialist or naval architect can help ensure accurate calculations based on your specific vessel’s design parameters.

Additionally, assessing the angle at which your sailboat shrouds intersect with the mast is essential for optimizing performance. An improper angle can lead to excessive mast bend or unwanted sagging of sails. Adjusting these angles through advanced tuning techniques like dynamic rigging allows for fine-tuning adjustments that improve windward performance and overall boat handling characteristics.

While analyzing all these technical aspects is crucial, it’s essential not to overlook the aesthetic element. Upgrading your sailboat shrouds presents an opportunity to add a touch of personality and uniqueness to your vessel. With a wide range of colors and finishes available, you can enhance the visual appeal of your rigging while still prioritizing performance.

One last consideration that should not be overlooked when upgrading shrouds is budget allocation. Sailboat shroud replacements can vary widely in cost depending on factors such as material choice, size, and customization options. It is advisable to establish a realistic budget beforehand and prioritize factors accordingly.

In conclusion, upgrading sailboat shrouds requires careful evaluation of various key considerations. From material selection to size determination, angle adjustments, aesthetics, and budget allocation – each aspect plays a vital role in optimizing your vessel’s performance on the water. By approaching this upgrade decision with a professional mindset while also injecting some wit and cleverness into the process, you can elevate both the functionality and allure of your sailboat shrouds. So set sail towards better performance enhancement by exploring these considerations in detail!

Recent Posts

- Sailboat Gear and Equipment

- Sailboat Lifestyle

- Sailboat Maintenance

- Sailboat Racing

- Sailboat Tips and Tricks

- Sailboat Types

- Sailing Adventures

- Sailing Destinations

- Sailing Safety

- Sailing Techniques

- Types of Sailboats

- Parts of a Sailboat

- Cruising Boats

- Small Sailboats

- Design Basics

- Sailboats under 30'

- Sailboats 30'-35

- Sailboats 35'-40'

- Sailboats 40'-45'

- Sailboats 45'-50'

- Sailboats 50'-55'

- Sailboats over 55'

- Masts & Spars

- Knots, Bends & Hitches

- The 12v Energy Equation

- Electronics & Instrumentation

- Build Your Own Boat

- Buying a Used Boat

- Choosing Accessories

- Living on a Boat

- Cruising Offshore

- Sailing in the Caribbean

- Anchoring Skills

- Sailing Authors & Their Writings

- Mary's Journal

- Nautical Terms

- Cruising Sailboats for Sale

- List your Boat for Sale Here!

- Used Sailing Equipment for Sale

- Sell Your Unwanted Gear

- Sailing eBooks: Download them here!

- Your Sailboats

- Your Sailing Stories

- Your Fishing Stories

- Advertising

- What's New?

- Chartering a Sailboat

Sailboat Rigging: Part 1 - Standing Rigging

When we talk about sailboat rigging, we mean all the wires, ropes and lines that support the rig and control the sails. To be more precise, the highly tensioned stays and shrouds that support the mast are known collectively as standing rigging , whilst the rope halyards, sheets and other control lines come under the heading of running rigging.

Some sailboats with unsupported masts, like the junk rig and catboat rigs have no standing rigging at all.

Bermudan sloops with their single mast and just one headsail will have a relatively simple rigging layout - those with a single set of spreaders especially so.

The most complex rigging of all will be found on staysail ketches and schooners with multi-spreader rigs.

Fairly obviously, the mast on a sailboat is an important bit of kit.

Let's make a start by taking a look at the standing rigging that holds it up...

Standing Rigging

Cruising sailboats will have their mast supported by 1 x 19 stainless steel wire in most cases, but some racing boats may opt for stainless steel rod rigging. Why? Well rod rigging has a stretch coefficient that is some 20% less than wire, but...

- It's more expensive than wire;

- It's more difficult to install and adjust;

- It suffers from metal fatigue, signs of which are difficult to spot;

- It's less flexible and has a much shorter useful life span

So it's 1 x 19 stainless steel wire for us cruising types.

Cap Shrouds

These are the parts of a sailboat's rigging that hold the mast in place athwartship. They're attached at the masthead and via chainplates to the hull.

Lower Shrouds

Further athwartship support is provided by forward and aft lower shrouds, which are connected to the mast just under the first spreader and at the other end to the hull.

The mast is supported fore and aft by stays - the forestay and backstay to be precise.

Cutter rigs require an inner forestay upon which to hang the staysail, which unlike a removable inner forestay, becomes an element of the overall rig structure.

As this stay exerts a forward component of force on the mast, it must be resisted by an equal and opposite force acting aft - either by swept-back spreaders, aft intermediates or running backstays.

Another stay that deserves a mention is the triatic backstay. This is the stay that is found on some ketches, and it's the stay from the top of the mainmast to the top of the mizzen mast.

It's a convenient alternative to a independent forestay for the mizzen. Although it makes a great antenna for an SSB radio , it does ensure that if you lose one mast, you're likely to lose the other.

Multi-Spreader Rigs

With the lower shrouds supporting the mast athwartship at the lower spreaders, intermediate shrouds do the same thing for any other sets of spreaders. These take the form of a diagonal tie between the inner end of one spreader and the outer end of the spreader below it.

Continuous or Discontinuous Sailboat Rigging

The shrouds on all single-spreader rig and some double-spreader rigs are continuous. With three or more spreaders, this arrangement becomes impractical - discontinuous rigging is the way to go. So what's that?

Well, if you consider the mast rigging as a series of panels, ie:~

- Lower Panel ~ From the deck to the first set of spreaders;

- Top panel ~ From top set of spreaders to the masthead;

- Intermediate Panels ~ Between each set of spreaders.

Then discontinuous rigging is when each shroud is terminated at the top and bottom of each panel.

The main benefits of discontinuous sailboat rigging is:~

- The rig can be more accurately set up, and

- Weight aloft is substantially reduced;

- It can be replaced in small doses.

Chainplates, Turnbuckles and Toggles

It's through these vitally important sailboat rigging components the shrouds are attached to the hull.

The chainplate is a metal plate bolted to a strongpoint in the hull, often a reinforced section of a bulkhead.

It must be aligned with angle of the shroud attached to it through a toggle, to avoid all but direct tensile loads.

Whilst cap shrouds will be vertical - or close to it - lower shrouds will be angled in both a fore-and-aft direction and athwartship.

Artwork by Andrew Simpson

Toggles are stainless steel fittings whose sole purpose in life is absorb any non-linear loads between the shrouds and the chainplate.

Consequently, they must be of a design that enables rotation in both the vertical and horizontal planes.

Note the split pin! These are much more secure than split rings which can gradually work their out of clevis pins - with disastrous results.

Turnbuckles, or rigging screws or bottlescrews, are stainless steel devices that enables the shroud tension to be adjusted.

Next: Part 2 - Running Rigging

Read more about Reefing and Sail Handling...

Headsail Roller Reefing Systems Can Jam If Not Set Up Correctly

When headsail roller reefing systems jam there's usually just one reason for it. This is what it is, and here's how to prevent it from happening...

Single Line Reefing; the Simplest Way to Pull a Slab in the Mainsail

Before going to the expense of installing an in-mast or in-boom mainsail roller reefing systems, you should take a look at the simple, dependable and inexpensive single line reefing system

Is Jiffy Reefing the simplest way to reef your boat's mainsail?

Nothing beats the jiffy reefing system for simplicity and reliability. It may have lost some of its popularity due to expensive in mast and in boom reefing systems, but it still works!

Recent Articles

Apla 42 Sailboat Specs & Key Performance Indicators

Aug 30, 24 02:51 AM

Ovni 445 Sailboat Specs & Key Performance Indicators

Aug 29, 24 03:44 AM

Catalina 34 Sailboat Specs & Key Performance Indicators

Aug 29, 24 12:14 AM

Here's where to:

- Find Used Sailboats for Sale...

- Find Used Sailing Gear for Sale...

- List your Sailboat for Sale...

- List your Used Sailing Gear...

Our eBooks...

A few of our Most Popular Pages...

Copyright © 2024 Dick McClary Sailboat-Cruising.com

PDRacer.com Cheap, Creative, and Having Fun On The Water

Making Stays / Shrouds for a sailboat mast

There numerous methods for making wire stays for your sailboat. This essay presents a simple method using nicopress ferrule cable clamp fittings which are swaged on using a cheap swaging tool. The toughest part seems to be figuring how how long to make the stays, this essay presents 2 methods.

Method 1 - Measure & Pray

If you are replacing an existing stay on a sail boat, you might have the old one and will know how long it needs to be. Or if you are setting up a new rig, you can use trigonometry or scale drawings to calculate how long your stay needs to be. Make sure to pray a lot while doing your calculations and take into consideration how long your mast & hull connections are like the chain plates and stay adjusters. If you screw up, there are a large variety of variable sized stay adjuster, tangs and stay extenders incase you make one too small.

Mark your wire so that it will be long enough to span the distance, plus go around the timble and back into the ferrules. You can calculate how much extra wire is needed by laying out the ferrules and rolling the thimble along the wire.

Method 2 - Setup & Cut

This is a quick and easy way to make a set of stays. First you need to get a general sense of how long the stay needs to be. Measure the distance from the mast step to the chain plate. Then clamp one end of a measure tape to the mast. Use a 2nd measure tape to get the side distance and presto, you have a good idea how long they are going to be.

Make a set of stays with only one end swaged and attach them to the mast. Setup your mast holding it upright with ropes. The ropes should be tied to the hull much further back than the chain plates so that they won't have as much tension on them. Tie the side ropes to the stern corners if you can, or thru the oar locks.

To hold the wire I use a cable clamp.

Setup your wire on the stay adjusters with their thimbles and ferrules. Use a screw on type cable clamp to hold the wire so you can crimp it. Setup all of the stays this way and take a good look at the rig. Adjust as needed.

I prefer to setup my stays so they are in the 2nd hole down. This allows me to loosen one or the other incase I screwed up and have the mast leaning enough to be noticed. Also it allows for the wire to stretch and gives me room to tighten it down later.

Crimp The Stays

This is a cheap swage-it tool that I purchased, it is just a pair of bars with bolts to create the clamping pressure. The bars have several half moon shapes in them to fit the different sized ferrules.

Here is the finished product, this is the forestay. I like to use quick pins that have a push button. They are kinda expensive so I attach them to the stay adjuster with a little safety wire -- which is crimped the same way the stays are. That way I won't loose them in the drink.

Site Map Articles Members Free PDRacer Plans Contact Shorty Books Search Advertise At PDRacer.com Support the club: Get a HIN Plate or Donate Subscribe To The PDRacer Newsletter

Copyright (c) 2003-2024 David Danes LLC, All Rights Reserved

What is a Shroud on a Sailboat? A Detailed Exploration

In the fascinating world of sailing, there’s a crucial piece of hardware known as a shroud on a sailboat. This integral part has quite a role to play, ensuring the stability and proper functioning of your seafaring vessel.

Like a trusted companion, it bears the strain of winds and waves, maintaining the mast’s vertical position. But what exactly is it? How does it work? Let’s dive into the details.

What is a Shroud on a Sailboat?

Picture yourself on a sailboat, your eyes following the sturdy mast upwards as it pierces the clear blue sky. It stands tall and unyielding, bearing the sails that capture the wind and drive you forward. But how does it maintain its vertical position in the face of gushing winds and raging storms? That’s where the shroud comes in.

Shrouds on a sailboat are essentially the standing rigging wires that run from the masthead to the sides of the boat. They offer lateral support, keeping the mast stable and upright. In simple words, shrouds are the strong arms that support the mast when the wind blows from the side.

Now, let’s peel back a layer and take a closer look at the different types of shrouds that help your sailboat function seamlessly.

Different Types of Shrouds

When it comes to the rigging of a sailboat, understanding the different types of shrouds goes a long way in ensuring the safety and performance of your vessel. Each type of shroud serves a unique purpose, working in harmony to uphold the mast’s stability. Let’s delve into the intricate world of cap shrouds, uppers, and lower shrouds, and unravel their unique roles.

Cap Shrouds

Imagine the mast of your sailboat as a towering fortress. It braves the wind, waves, and weather, standing tall and strong. But even a fortress needs its guards, and in the case of your mast, these are the cap shrouds.

Cap shrouds extend from the very top of the mast to the sides of the boat, anchoring it firmly against the lateral forces induced by the wind and the sea. They act as the primary support system, preventing your mast from swaying excessively side-to-side. But their role isn’t limited to just fortifying the mast. They also contribute to the overall stability and balance of the sailboat, allowing you to navigate the waters with confidence.

For a detailed exploration of various sailboat types and to understand where cap shrouds play a pivotal role, check out our extensive guide on Different Types of Sailboats Explained .

While the cap shrouds guard the topmost part of the mast, the section just below the masthead, known as the uppers, has its line of defense too. Uppers, or upper shrouds, provide crucial support to this part of the mast.

They work hand-in-glove with the cap shrouds, forming a second line of defense against the lateral forces. Uppers ensure the part of the mast they hold remains steadfast and upright, contributing to the overall rigidity of your sailboat’s structure.

Lower Shrouds

And then we come to the base. The lower part of the mast, which takes on a significant amount of strain and stress. This is where the lower shrouds step into the picture.

Lower shrouds secure the lower third of the mast, reducing the side-to-side motion that could result in undue strain on your boat’s structure. By minimizing this movement, they prevent potential mast damage and ensure your sailboat maintains its balance.

The type and number of shrouds used on a sailboat can vary. Factors such as the sailboat’s design, its size, and the conditions it will sail in, all influence the shroud setup. Some sailboats may even feature intermediate shrouds, adding another layer of support.

Now that you’re familiar with the various types of shrouds and their roles, it’s time to explore the materials they are crafted from. Because just like the sails that catch the wind (learn more in our Comprehensive Guide on Types of Sails on Sailboats ), the material of your shrouds significantly influences your sailing experience.

Now that you know the roles of different types of shrouds, let’s talk about what they’re made of.

Materials Used for Shrouds

Shrouds are typically made of stainless steel wire, which offers durability and strength. However, the advent of modern materials has seen a shift towards synthetic fibers such as Dyneema and Vectran . These materials offer the same level of strength but at a fraction of the weight, making them an excellent choice for racing yachts. You can learn more about such yachts in our article Racing Sailing Yachts – Black Sails .

| Material | Advantages | Disadvantages |

|---|---|---|

| Stainless Steel | Highly durable, resistant to rust and corrosion | Heavier, requires regular inspection for wear and tear |

| Dyneema and Vectran | Lightweight, high strength, resistant to UV degradation | Costlier, requires replacement more often |

Just as you would pay attention to the quality of sails for your boat (check out our comprehensive guide on Types of Sails on Sailboats ), selecting the right material for shrouds is equally crucial.

Now, having understood the different types of shrouds and the materials used, let’s turn our focus to one of the most crucial aspects of shroud setup – the proper tension.

Importance of Proper Shroud Tension

Just like a finely tuned instrument, your sailboat requires a perfect balance. A big part of that balance lies in achieving the right shroud tension. Too loose, and the mast could sway more than necessary, affecting your boat’s performance and potentially causing damage. Too tight, and you could put excessive pressure on the hull, leading to unwanted strain and even structural damage. The right tension ensures optimal sail shape and the best performance of your vessel.

Finally, let’s discuss the critical aspect of maintaining and replacing shrouds, which ensures your sailboat continues to ride the waves effortlessly.

Maintaining and Replacing Shrouds

Maintaining your shrouds isn’t a one-off task; it’s an ongoing commitment. Regular inspections for wear and tear, corrosion, and proper tension can keep potential issues at bay. Small problems can be spotted and fixed before they snowball into expensive repairs or dangerous situations at sea.

Replacing shrouds can be a tricky business, depending on the size and complexity of your rigging. While minor repairs can be done by a knowledgeable sailor, it’s recommended to hire a professional when it comes to complete replacement.

Costs for shroud replacement can vary, depending on the material used, the size of the boat, and the complexity of the rigging. However, investing in quality shrouds and proper maintenance can save you from potential damage and costly repairs down the line.

In the fascinating world of sailing, understanding the nitty-gritty of each component makes the journey even more rewarding. We hope this article has shed light on the importance and functionality of shrouds on a sailboat. Next time you’re out sailing, remember to appreciate these silent warriors that help navigate the high seas.

For more exciting content about the world of sailing, be sure to check out our list of Best Sailing Movies and learn more about Sailboat Racing Flags and Signals .

Table of Terms about Shrouds on Sailboats

| Shroud | A standing rigging wire on a sailboat that provides lateral support to the mast. |

| Types of Shrouds | There are three primary types of shrouds: cap shrouds, upper shrouds, and lower shrouds. Each provides support to different sections of the mast. |

| Material Used | Shrouds are typically made from stainless steel but modern sailboats can also use synthetic materials like Dyneema and Vectran. |

| Shroud Tension | Proper shroud tension is essential for maintaining balance and preventing damage to the boat’s structure. |

| Maintenance and Replacement | Shrouds require regular inspection for wear and tear, and replacements should be done by professionals, considering the complexity of the rigging. |

FAQs about Shrouds on Sailboats

What is a shroud on a sailboat.

A shroud is a standing rigging wire that provides lateral support to the mast of a sailboat.

Why are shrouds important on a sailboat?

Shrouds maintain the stability and vertical position of the mast, enabling optimal sail performance and boat balance.

What are the different types of shrouds?

The three main types of shrouds are cap shrouds, upper shrouds, and lower shrouds, each supporting different sections of the mast.

What materials are commonly used for shrouds?

Shrouds are typically made from stainless steel, but modern variants can also use synthetic materials like Dyneema and Vectran.

How often should shrouds be replaced?

The frequency of replacement depends on the condition of the shrouds. Regular inspection helps detect wear and tear, dictating when a replacement is needed.

- Recent Posts

- The Role of Cargo Ships in Global Trade – August 22, 2024

- Report: Yang Ming’s YM Mobility Explosion at Ningbo-Zhoushan Port – August 9, 2024

- Understanding Drillships: Types, Key Features and Advancements – August 1, 2024

About the author

I worked as an officer in the deck department on various types of vessels, including oil and chemical tankers, LPG carriers, and even reefer and TSHD in the early years. Currently employed as Marine Surveyor carrying cargo, draft, bunker, and warranty survey.

Latest posts

The Quality Control Process in Marine Manufacturing

Companies in the marine manufacturing space must have tight and effective quality control processes. What steps should an effective quality control process include?

The Role of Cargo Ships in Global Trade

Contents show Volume of Goods Transported by Sea Key Global Trade Routes Economic Impact of Maritime Shipping Types of Cargo Commonly Transported Environmental Considerations Conclusion Cargo ships are the lifeline […]

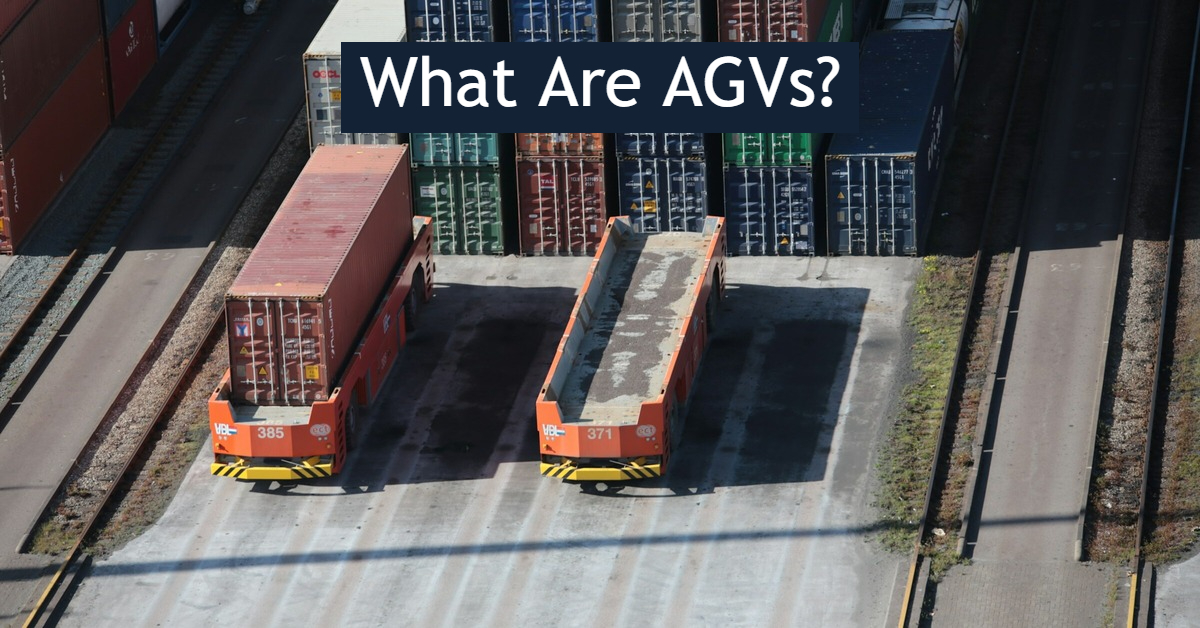

What Are AGVs? Automation Becoming Increasingly Common in Seaports

What are AGVs? Automated guided vehicles can minimize the troubles of manual operations and enhance seaport operations.

- Stay Tuned with Vela!

How to measure standing rigging on your sailboat.

Posted by Rod Favela on Nov 28th 2015

On discontinue rigs it is important to properly identify each on of the shrouds using the typical rigger's nomenclature: V1 D1 V2 D2 .. and so on. Don't wait until the wire starts to break or rust too much. Be proactive about maintaining your boat and change the rigging every ten years. Keep in mind that crystallization and fatigue are rarely observed on the wire and they may be the hidden enemy leading toward a rig failure. The crew at Vela Sailing can help you determine the best way to have your rigging finished and installed, using the best materials on both types of terminals: swage and swageless (Sta-Lok, Hi-Mod, etc). Don't wait until is too late and change your rigging now! Go sailing...sail hard!

- #measuring rigging

- #sailboat rigging

- #standing rigging

- Forums New posts Unanswered threads Register Top Posts Email

- What's new New posts New Posts (legacy) Latest activity New media

- Media New media New comments

- Boat Info Downloads Weekly Quiz Topic FAQ 10000boatnames.com

- Classifieds Sell Your Boat Used Gear for Sale

- Parts General Marine Parts Hunter Beneteau Catalina MacGregor Oday

- Help Terms of Use Monday Mail Subscribe Monday Mail Unsubscribe

pvc shroud covers

- Thread starter kito

- Start date Apr 7, 2013

- Catalina Owner Forums

- Catalina 22

I want to install some homemade pvc shroud covers on my c22. I am trying to figure what diameter and lengths I need for each of the 6 stays. I was thinking 4' on the front lowers, 3' on the uppers and 2' on the back lowers. Also, do you cap the tops or just leave them open?

Kito, Here's what our local C22 fleet captain recommends for our club: "Shroud Rollers A good idea to improve tacking is to install shroud rollers on the upper and forward shrouds. This can be done easily by installing a 1" diameter schedule 200 PVC pipe over the shrouds. 36" roller tube on the forward lowers and a 12-24" roller tube on the uppers." I think mine are 4' on the forward lowers, and 3' on the uppers. No caps. We don't bother with the rear lowers, as the jib sheets never seem to hang up on them. Stan

Attachments

Sched 200? Or more like DWV weight...

justsomeguy

As light as possible.

I used 3/4 PVC with caps drilled. Covered the PVC with Sunbrella fabric...easy and looks nice. Super cheap and brought some color to the deck. Covered the remaining wire with flex plastic tubing from Home Depot like you would expect to see feeding the H2o to a fridge. This was a cheap option and looks good IMO.

Nrmlspeed said: I used 3/4 PVC with caps drilled. Covered the PVC with Sunbrella fabric...easy and looks nice. Super cheap and brought some color to the deck. Covered the remaining wire with flex plastic tubing from Home Depot like you would expect to see feeding the H2o to a fridge. This was a cheap option and looks good IMO. Click to expand

That does look nice. I guess painting them blue would look nice for a while until they get all scratched up. Did you drill a hole in the caps and cut a slit for the wire? Also, just wondering if covering the whole wire with clear tubing would retain moisture.

Schedule 20 is what you'll find at most suppliers. Never heard of 200 but I learn something every day.

Standard weight PVC plumbing pipe/tube is called schedule 40. The lighter gage stuff used on the tailpiece and trap parts of under sink type PVC is called DWV weight - by some - as 20 gage. Gage determines wall thickness, not diameter. The wall thickness of various "weights" of PVC tubing are critical to rigidity - and their ability to withstand more or less pressure. Given this application is purely a means to "dress up" rigging so as to minimize snagging sails and socks from clevis's, cotter pins and clips - light weight, is the preferred PVC type. Not to say PEX "stick" (rigid as opposed to rolled/curved) aren't just as practical to use. Given PEX "stick" tubing and PVC can be purchased in any i.d., both work well and price alone may be the deciding factor between the two?

I picked up 10' 1" dwv at lunch. 2 3' and 2 2' sections should do it. Not going to worry about the aft lowers for now. Btw, the sch 200 mentioned earlier I believe what was meant is 200 psi....not schedule 200.

The shroud covering/flex tube is not tight. It easily slides up and down. Very similar to the white plastic that West Marine sells but not nearly the cost. In my climate Im fearless about the rusting issue...your climate might be no bueno. I simply ran a razor down the side of the tubing and snapped them on.

I installed mine last night. I painted the tubes a royal blue color with Krylon Fusion paint and kepted the caps white. Looks great. I figure I can always touch up the paint when it gets scratched up. I just have to figure a way to fill in the slot I cut in the caps now. The wire wants to work its way into those slots and keeps the tube from spinning straight......maybe drill a hole next to the center and drive a wood dowel into the cap to keep the wire in the center?

- This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register. By continuing to use this site, you are consenting to our use of cookies. Accept Learn more…

IMAGES

VIDEO

COMMENTS

Intermediate shrouds (4) extend from mid-mast panel to deck. Lower shrouds extend from below the spreader-base to the chainplates. Fore- (5) and Aft-Lowers (6) connect to the deck either forward or aft of the cap shroud. Discontinuous rigging, common on high performance sailboats, is a series of shorter lengths that terminate in tip cups at ...