Yachting World

- Digital Edition

Furlers: All the latest kit on the market

- Toby Hodges

- May 18, 2021

Toby Hodges takes a look at the significant developments that have been a feature of the furler market in the last few years, and picks out some of the best options on the market

Easy reefing on the Kraken 66 White Dragon during our heavy airs test, with an in-boom system by Southern Spars. Photo: Kraken Yachts

A tug on the working sheet and the furling line, the offwind sail spins open and your boat surges forward, the great joy of a furlers doing that for which they are designed.

You’re content in the knowledge that it’s simply a case of releasing the sheet and pulling on the furling line again to have all that sail area tamed and back under wraps in seconds – no wrestling with poles, no dancing around a foredeck grappling with socks or buckets necessary.

Continuous line furlers, together with the torsional ropes or cables around which the sails furl, have given us a lot to be grateful for.

The ability to manage large code or asymmetric sails with minimal crew is becoming ever easier thanks to advances in structured luff sails and the technology and reliability of furlers.

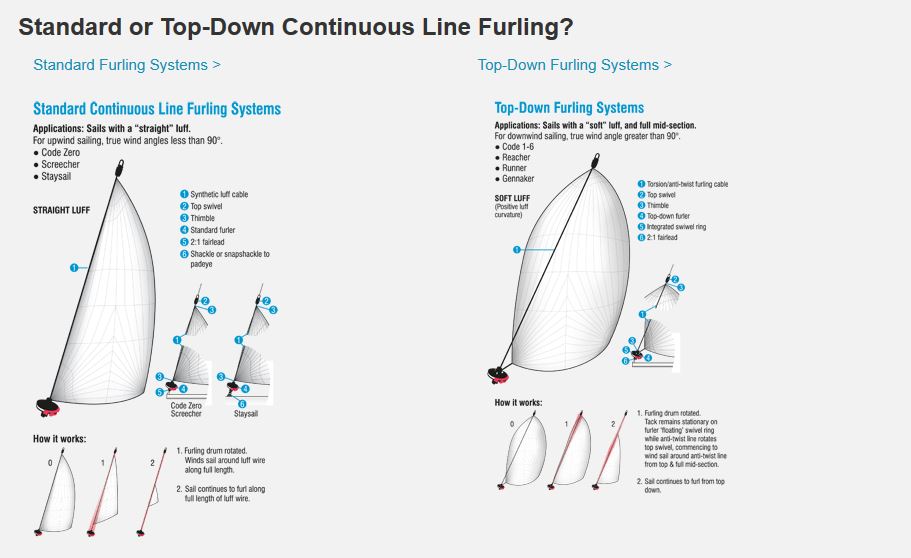

However, choosing the right furler for your bowsprit or stemhead can be quite complex. Are you running only one type of sail off each of your furlers and is that a Code 0 for reaching or a free flying A-sail for sailing deeper angles – or both?

The answer will likely determine whether it’ll be more practical to furl the sail from the bottom-up or, as has become more popular, from the top-down.

Here, we take a look at Karver’s latest KF V3 model as well as the current range of options in this sector.

Article continues below…

Is in-boom furling the next big thing in sail handling technology?

Even though this remains an expensive option, in-boom furling is one that a growing number of boat owners are adopting.…

Facnor FD190 flat deck furler

Although not a new product, this webbing line furler is rarely seen outside of French performance cruising yachts, writes Rupert Holmes.…

Most manufacturers of furlers now offer top-down units, either as a dedicated drum or as an adapter for their existing units. “We have seen a significant decline in Code 0s, with 80% of enquiries in the last 12 months for asymmetric sails and more and more for top-down furlers,” says Phil Anniss, director of Upffront.

His company supplies from all manufacturers, so he’s a useful source for discussing the latest trends in furlers. Upffront’s core market is 30-50ft cruising yachts and Anniss says these sailors increasingly want to be able to use top-down systems on their existing gennaker/A-sails rather than have to get a new sail.

“We sell the idea of a top-down adapter to allow people to use the same drums for furling both Code 0s and asymmetric sails,” he says.

Karver KF V3

French hardware company Karver has been helping to take the sweat out of furling flying sails since the launch of its first KF V1 furler in 2004.

Its latest V3 version targets a particularly broad tranche of the sailing market. A patented carbon and Kevlar continuous line wheel helps to reduce weight – the V3 is much lighter than its aluminium wheel predecessor – while the Kevlar teeth also create less friction and wearing.

Commercial director Tanguy de Larminat explains that the gains the company has made in weight has allowed for a reinforced structure while retaining the high performance.

The variety of units now offered should appeal to both racing and cruising sailors. There are eight sizes from 1.5-12 tonnes SWL (safe working load), all available in four different versions: Standard, Racing, Classic and Structural.

Interestingly, Karver has moved away from dedicated top-down units, preferring top-down adapters for all its new range.

A large drum version is available on the 1.5 and 3.0 models, which provides power to start the furl if doing so only by hand, but may not suit top-down systems that rely on speed.

De Larminat says Karver is also reprising its work with sustainable materials. “We are applying what we started to do 10 years ago. “Most of our carbon products can be produced by replacing the carbon with bio-sourced material such as bamboo or linen fibres, with no loss of performance.”

The price of KF furlers remains the same as previous models.

KF V3 3.0 Standard Price: €1,491. www.karver-systems.com

Bamar RLG EVO 10

The EVO is the latest-generation Bamar furler, which has an independent tack swivel mounted on the aluminium drum. This is a simple, well-engineered and light model for its 3.0 tonne SWL. The jaw width makes it difficult to use the bottom-up drum for a standard top-down cable, however Bamar has its own Rollgen stay that plugs into the EVO drum. Price: €1,634. www.bamar.it

SeldÉn CX25

Seldén offers a GX range to suit gennakers or asymmetric spinnakers, or a CX range designed for Code 0. The latter is perhaps more versatile as they can use top-down adapters.

The CX drum size is small for top-down furling but it has a large jaw width to allow for adequately sized rope diameter.

In a similar vein to Harken, the Seldén drums are designed to work with its own branded cables. Seldén has a very competitive price point for its CX range, which also includes torsional rope.

Price: €1,427. www.seldenmast.com

Facnor FX+ 2500

This offers impressive performance for the price in one of the lightest units available.

The new generation FX+ range was updated last year with new guides to secure the furling line around the drum. The well-rounded design has a decent jaw width and the option for a top-down adapter.

The Facnor FX+ is arguably the closest competitor to the Karver KF V3.

Price: €1,785. www.facnor.com

Harken Reflex 2

The Reflex furling systems have been developed for optimum use with load-sharing code sail technologies. They come with top-down adapters (pictured) but only for use with Harken cables – so are sold as complete kits together with Harken’s torsional rope.

Good value as long as you don’t need to interface it with an existing torsional cable. Price: €1,642. www.harken.com

Profurl NEX 2.5

This has one of the largest drum diameters to promote fast furling with minimal effort. Ratchet versions are available for greater control.

The NEX system is designed to be compatible with Profurl’s proprietary Spinex, a system with plastic balls around the torsional rope.

The NEX 2.5 is advised for cruising yachts up to 42ft.

Price: €1,561. www.profurl.com

Ronstan Series 160

Ronstan is one of the few remaining companies offering dedicated top-down drums. This is particularly appealing for owners of smaller yachts/sportsboats who typically only use A-sails.

However, at this 160 drum size, it may make more economic sense to choose a furler with a top-down adapter for use with multiple sails.

Price: €2,261. www.ronstan.com

Ubi Maior FR125

Ubi Maior has a full range of dedicated top-down units or drums with adapters manufactured from single blocks of aluminium. These have high working loads and small drums, but jaw widths may limit practicality for top-down Code 0 furling.

Price: €2,002. www.ubimaioritalia.com

If you enjoyed this….

Yachting World is the world’s leading magazine for bluewater cruisers and offshore sailors. Every month we have inspirational adventures and practical features to help you realise your sailing dreams. Build your knowledge with a subscription delivered to your door. See our latest offers and save at least 30% off the cover price.

Please verify you are a human

Access to this page has been denied because we believe you are using automation tools to browse the website.

This may happen as a result of the following:

- Javascript is disabled or blocked by an extension (ad blockers for example)

- Your browser does not support cookies

Please make sure that Javascript and cookies are enabled on your browser and that you are not blocking them from loading.

Reference ID: 52beb594-33a9-11ef-9d58-ee056dbee073

Powered by PerimeterX , Inc.

Mastering the Art of Sail Handling: A Comprehensive Guide to Mainsail Furlers and Roller Furling Systems

- Mastering the Art of Sail Handling: A Comprehensive Guide to Mainsail Furlers and Roller Furling Sys

Sailing can be a joy, but managing sails can often be challenging, especially for those new to the sport. One crucial piece of equipment that can make life easier on the water is a mainsail furler. This guide delves into everything you need to know about mainsail furlers and roller furling systems, exploring their benefits, installation, and maintenance.

What is a Mainsail Furler?

A mainsail furler is a device designed to roll up the mainsail into the mast or boom, making it easier to deploy and stow the sail. This mechanism significantly reduces the physical effort required to manage the sail, especially in windy conditions. Sail furling systems are essential for improving the overall sailing experience. They offer convenience, safety, and enhanced performance, making them a must-have for both casual sailors and seasoned mariners.

Types and Mechanisms of Mainsail Furling Systems

Traditional mainsail furling involves manually rolling the sail around the boom or bundling it on the deck. While effective, this method can be labour-intensive and time-consuming. In-mast furling systems roll the sail into the mast itself. This method is popular for its ease of use and the sleek profile it provides, making it a preferred choice for many sailors. In-mast furling systems use a rotating mechanism within the mast to roll the sail.

In-boom furling systems roll the sail into a specially designed boom. This method offers excellent control over sail shape and is ideal for performance-oriented sailors. In-boom furling systems use a similar rotating mechanism, but the sail is rolled into the boom rather than the mast.

Advantages and Disadvantages of Mainsail Furlers

Mainsail furlers allow for furling and unfurling the sail from the cockpit, enabling quick adaptation to changing weather conditions without leaving the helm. By reducing the need to go on deck to manage sails, mainsail furlers enhance safety, particularly in rough seas. This feature is invaluable for solo sailors and small crews. Modern furling systems allow for precise control over sail shape, leading to improved sailing performance. Whether racing or cruising, the ability to adjust sail trim easily can make a significant difference.

Like any mechanical system, mainsail furlers can fail. Regular maintenance is essential to ensure reliable operation, and sailors should be prepared for potential issues. Mainsail furlers can be expensive to purchase and install. However, the benefits they offer often outweigh the initial investment for many sailors.

Choosing and Installing the Right Mainsail Furler

When choosing a mainsail furler, consider factors such as the size of your boat, your sailing style, and your budget. It's also essential to choose a system compatible with your existing rigging. Popular brands of mainsail furlers include Selden, Harken, and Furlex. Each brand offers various models tailored to different types of boats and sailing needs.

While some experienced sailors may opt to install a mainsail furler themselves, professional installation is often recommended to ensure proper setup and avoid potential issues. Follow these steps for a smooth installation: gather all necessary tools and equipment, safely remove any existing sail handling equipment, follow the manufacturer’s instructions to install the furling system, and test the system thoroughly.

Maintenance of Mainsail Furlers

Regularly inspect your mainsail furler for signs of wear and tear. Look for issues such as frayed lines or damaged components. Keep the moving parts of your furling system well-lubricated and clean. This maintenance will ensure smooth operation and extend the life of the system. Common issues with mainsail furlers include jamming and uneven furling. Regular maintenance and prompt attention to problems can prevent these issues from becoming serious.

Read our top notch articles on topics such as sailing tips, lifestyle and destinations in our Magazine .

Check out our latest sailing content:

Fishing and sailing: where to sail for the best catches, skippered boats: how to pack for a yachting holiday, boat rental with skipper: everyone can go to sea, skippered boats: myths about sailing, sail from lefkada for 14 days. where to, what not to miss when visiting lefkada, skippered boats: step-by-step boat rental, where and why to sail from lefkas marina, don’t panic: handling maritime emergencies, skippered boats: how to choose a boat, the best sailing routes from biograd na moru, yachting away from ourselves: a voyage to inner peace, sail to the 7 most beautiful sights in greece, skippered boats: how to put together a crew, skippered boats: the most popular yachting destinations, what skipper's licence do i need, skippered boats: what you can experience when yachting, from lefkada or corfu to paxos and antipaxos, discover the paradise of paxos and antipaxoss, skippered boats: typical day on board, skippered boats: what it actually looks like on a boat, discover corfu: sailing adventure in the ionian, sextant and navigation: survival without gps, 5 best sailing routes in the bahamas, skippered boats: how much does a boat holiday cost, yachting guide to the bahamas, the ultimate yacht cleaning kit, introduction to chartering with a skipper, traditional sailor tattoos: meaning of the swallow, the most popular catamarans of 2023.

Roller Furling Systems for Headsails

A roller furling system allows the headsail to be rolled around a stay or foil, making it easy to deploy, reef, and stow the sail. While both systems serve similar purposes, headsail furlers are typically simpler and more robust, designed to handle the higher loads placed on headsails.

When selecting a roller furling system, look for features such as a reliable bearing system, ease of operation, and compatibility with your existing rigging. Top brands for roller furling systems include Harken, Furlex, and Profurl. Each offers a range of models suitable for different boat sizes and sailing styles.

Installation and Maintenance of Roller Furling Systems

Follow these steps for a smooth installation process: prepare the stay by ensuring it is clean and free of damage, assemble the foil by following the manufacturer’s instructions, secure the furling drum to the base of the stay, and test the system to ensure smooth operation. While DIY installation is possible, professional help can ensure the system is correctly installed and functioning optimally.

Perform routine checks to ensure the system operates smoothly. Look for wear on the furling line and inspect the drum and bearings. Common problems include difficulty furling or unfurling and uneven rolling. Address these issues promptly to maintain the system's reliability.

Popular Sail Brands: Elvstrom Sails UK

Elvstrom Sails is renowned for producing high-quality sails tailored to various sailing needs. Based in the UK, they offer a range of sails designed for performance and durability. Elvstrom Sails are known for their innovation, quality materials, and excellent craftsmanship. Choosing Elvstrom ensures you're getting a sail that will perform well and last.

Sail furling systems, whether for the mainsail or headsail, offer significant benefits in terms of convenience, safety, and performance. By choosing the right system and maintaining it properly, sailors can enhance their sailing experience and enjoy smoother, more efficient sail handling.

So what are you waiting for? Take a look at our range of charter boats and head to some of our favourite sailing destinations.

I am ready to help you with booking a boat for your dream vacation. Contact me.

Denisa Nguyenová

- BOAT OF THE YEAR

- Newsletters

- Sailboat Reviews

- Boating Safety

- Sails and Rigging

- Maintenance

- Sailing Totem

- Sailor & Galley

- Living Aboard

- Destinations

- Gear & Electronics

- Charter Resources

Top-Down Furling 101

- By Sean McNeill

- Updated: September 20, 2016

For many years the spinnaker sock has been the primary choice for shorthanded cruising sailors who fly big, colorful downwind sails. The sock is a simple device comprised of a funnel, a retrieval line and a nylon sleeve. To set a kite, you simply raise the funnel to the head of the sail, trim the spinnaker, and begin an enjoyable off-wind cruise.

Yet spinnaker socks can be hit-or-miss affairs. On some boats they work beautifully. On others they’ve been known to create macramé at the masthead or, in worst-case scenarios, slice the sail. But there’s one piece of equipment that can eliminate the sock and potentially make sailhandling much safer. Top-down roller furlers have become de rigueur for the superyacht crowd and offshore racing sailors. These furlers are so named because they furl a sail from the head down rather than the tack up.

How They Work

Rolling from the top down is a better action for today’s asymmetric off-wind sails, such as gennakers or screachers (see “Take It From the Top,” page 77). These sails typically have a luff length that is slightly longer than the leech length, a midgirth that is greater than the foot length, and a high clew point. Because of the free-flying luff and the ability to tuck away any additional sail material in the midgirth section, the sail is furled from the top down.

Top-down furlers can be easier and safer to use than a sock. Because the sail is rolled and not as exposed to the wind, top-down furlers may be hoisted and secured in place at the dock or mooring. A sock must be hoisted when desired and immediately stowed belowdecks upon retrieval. With a top-down furler, the sail may be rolled up if the wind pipes up, but it doesn’t have to be lowered until you’re safely moored. Rather than standing on a potentially pitching, heaving, rolling foredeck with your arms above your head, wrestling with a sock’s retrieval line, you can operate the roller furler from the safety of the cockpit, using winches and clutches. But rolling the sail can be tricky, and if not performed correctly, it is usually where the operation goes wrong.

A sock works well because it envelops the entire sail, leaving nothing exposed to a strong gust that could inhibit a clean douse. With a top-down furler, the boat should be at a certain angle of sail, with an apparent-wind angle between 120 and 160 degrees (depending on wind strength and sail area) and with a constant amount of tension on the sheet to roll the sail properly. If any of the leech is left exposed, a strong gust could catch it and make it more difficult to stow the sail in its bag and unfurl it the next time. Or if the sheet pulls down on the clew excessively and stretches the leech, the sail won’t roll properly. In another scenario, you might encounter the reverse roll effect, wherein the foot of the sail is wrapped up as the sail is being unfurled, causing a cluster of immense proportions.

The key component of a good top-down furling system is the headstay cable, also called an anti-torque rope or tension cable. Regardless of the name, the stronger the cable, the better it is. With top-down furlers, the tack is mounted on a ring that encircles the anti-torsion cable just above the furling drum, which allows the head to begin furling before the tack. A taut cable will ensure torque is transferred evenly for the length of the cable, and that it remains in-line throughout the furling maneuver, which also aids a proper furl. You don’t want the cable to start bowing during the furling process, as it will lead to a bad furl and difficulties the next time you want to deploy the sail. The anti-torsion cable is what sets a top-down furling system at a high price point.

“For good spinnaker furling, a line that transmits torque very well is essential,” says John Franta, of Colligo Marine, which has made top-down furlers for asymmetric sails for three years. “You will have issues furling and unfurling your asymmetric sail with a twisty line. We recommend two hours to a couple of weeks to learn how to use the top-down system, because each system reacts differently based on the cut of the sail.”

Among the best anti-torsion cables on the market is the DynIce furling cable, sold with the Colligo, Profurl and Seldén systems. Manufactured by Hampidjan of Iceland, the cable has a core of DynIce Dux, a heat-set material with exceptional breaking loads and minimal constructional elongation. It has a double-braided cover of Dyneema SK75. A final polyester cover ensures the sail doesn’t stick to the cable. Other anti-torsion cable manufacturers include Future Fibres, Marlow, Harken and New England Ropes.

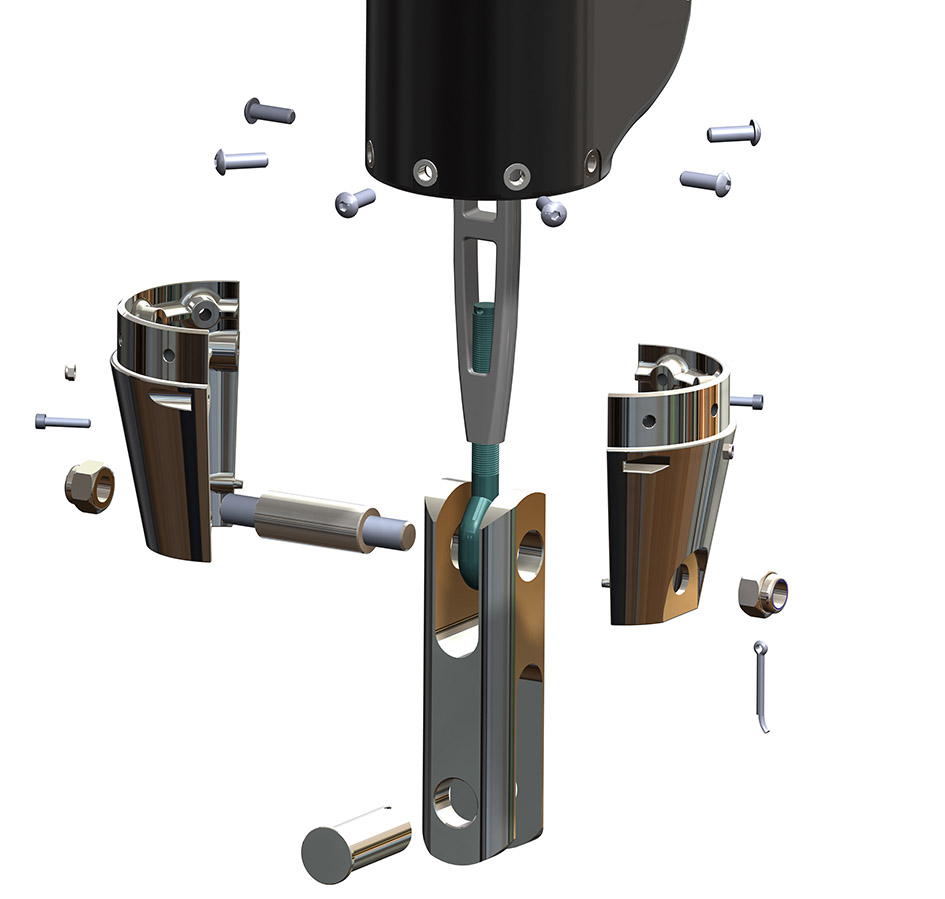

A basic top-down furler set will include the furling drum and a head swivel that attaches to the halyard. The drums and swivels are usually made of aluminum, titanium or stainless steel, and all have some sort of protective wrap to prevent the equipment from damaging the boat and mast. The furling drum must be tacked to a point that is forward of the headstay (which might mean adding some sort of bowsprit to some yachts). Most of the units come with quick-release pins to make removing the sail from the furling drum and head swivel easy.

Look for an adjustable tack line to set luff tension and for fine-tuning the sail shape. Tension the luff to make furling more efficient, and ease it when the sail is unfurled to induce more depth in the sail for better performance. Also pay attention to the covering on the anti-torsion cable. You don’t want the cable to damage the sail as it rolls.

There are many options in the marketplace for top-down furlers. We’ve chosen to highlight models from Bamar, Colligo, Harken, Profurl, Ronstan and Seldén, as they run the range from simple (Profurl) to robust (Bamar). It should be noted that these manufacturers market both bottom-up and top-down furler units. In most cases, a company’s top-down furler is developed from its bottom-up units. For the purpose of this story, we’ve focused on the top-down units only. Finally, we haven’t included the high-end custom units for which companies such as Karver and KZ Marine are renowned.

Ultimately, a spinnaker sock is the least expensive solution to spinnaker handling, costing around $1,500. Top-down furlers start at that price and can rise to $5,000 or $6,000 quickly, depending on the size of your boat, the sail, and the anti-torsion cable. Your choice will depend on your budget and your sailhandling requirements.

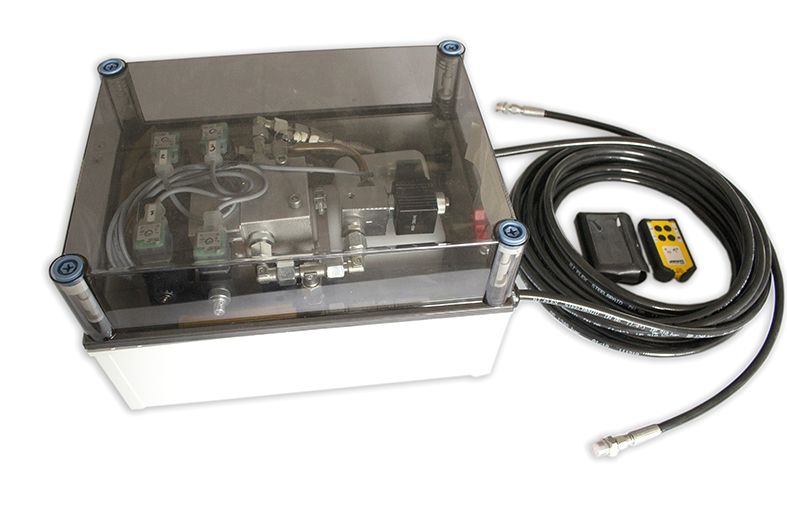

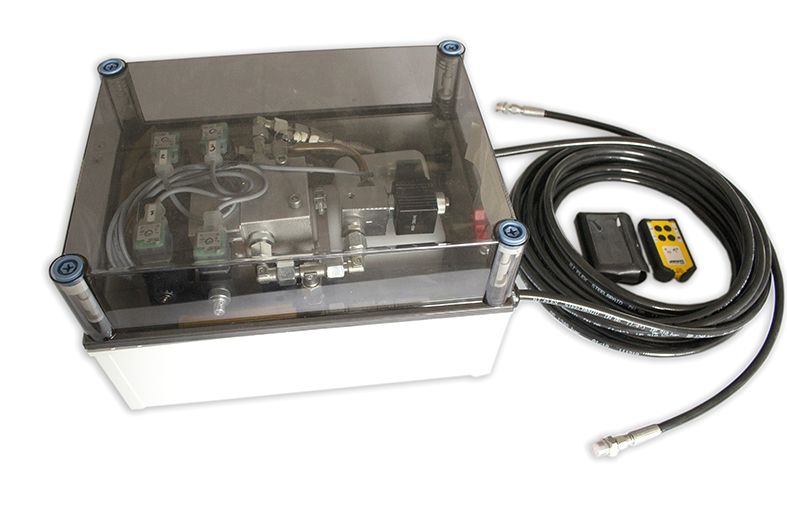

An industry leader in the category, Bamar conceived of the top-down furler 12 years ago. In 2004, its motorized RollGen-Code furler won the overall DAME Design Award, which recognizes outstanding innovation for new products and accessories in the marine industry. The RollGen furler may be used with asymmetric spinnakers requiring a top-down furl and with code sails (like the code zero) that are furled traditionally, from the tack up. The system is driven either manually or by a hydraulic or electric motor that utilizes a special self-aligning spherical construction. It is designed to be flush-mounted on deck.

The RollGen furler can be used on boats ranging from 25-footers to superyachts, with sail areas from 1,100 square feet (safe working load of 4,400 pounds) to 4,600 square feet (safe working load of 33,000 pounds).

Bamar’s RLG Evo is an evolution of its RollGen system and ideal for code sails, staysails, gennakers and asymmetric spinnakers with a free-flying luff. Designed for any size boat, the RLG Evo is a low-profile unit constructed of Ergal aluminum, 17-4PH steel and carbon-fiber drum cages (for the larger sizes).

Bamar offers two types of anti-torsion cables. One is a Dacron-cored cable for use with its smaller furlers. Bamar’s top-of-the-line cable is its 3K Stay, constructed of Technora, a high-tech aramid synthetic fiber with high tensile strength and long-term dimensional stability. The core is covered with three layers of Technora, each wound more tightly than the previous. All of the stays have a high-strength foam-rubber gaiter over the cable to protect the sail from abrasion and wear during the furling process.

Bamar sells five models of its RLG Evo line, for boats ranging in size from 26 to 120 feet, or working loads from 4,400 to 33,000 pounds. The prices range from $2,425 for the RLG Evo 08-15M to $3,750 for the RLG Evo 10-17M and $6,750 for the RLG Evo 20. Adding the optional 3K stay increases the price to $5,175 for the RLG Evo 10 and $8,950 for the RLG Evo 20. (The 3K stay is not offered with the RLG Evo 08; it may be purchased separately.)

Colligo Marine

Colligo Marine offers three unique models designed with maintenance-free bearing systems that can all be taken apart and serviced if needed. The aluminum furling drum has a plastic Delrin guide around the drum to prevent it from damaging the boat. The CN3S and CN5S are robust designs for active cruising. They both have angular, double-row sealed bearings to handle both thrust and axial loads. The CN3S is recommended for sails up to 600 square feet and has a safe working load of 3,000 pounds. The CN5S is for sails up to 1,000 square feet and has a safe working load of 5,000 pounds.

The CN1.5S is a lighter-weight version of the CN3S, designed for smaller sail areas. It has the same 3,000-pound safe working load as the CN3S but comes with a ceramic bearing system and is designed for sails up to 500 square feet. “Sizing also depends on sail type and weight, predicted usage, and boat geometry,” says Colligo’s John Franta.

The Colligo CF1.5S is priced at $1,395, the CN3S at $1,525, and the CN5S at $2,500. Those prices are for the furling drum and head swivel only and do not include the continuous furling line for the drum or the anti-torsion cable, which will add anywhere from $300 to $800 to the final price tag. Colligo also manufactures furling-line terminators (“furlinators”) and special clamps for torque lines that can be removed to reset the length if it isn’t cut right the first time.

Harken recently joined the top-down fray with its new Harken Reflex furling system. “The key is in the cable,” says Jim Andersen, the company’s U.S. sales manager. To provide a torsion cable stiff enough to deliver torque to the top of the sail, where it’s needed to begin furling, the company developed its own brand of cable that consists of a braided polyester core covered with a stainless-steel mesh. The cable is then coated with Santoprene, a thermoplastic covering. Because of the cable’s stiffness, it doesn’t need to be cranked bone-tight, as some top-down furlers require, which means there’s less load on the halyard, sprit and tack fitting. Still, the cable is flexible enough that once furled, the sail can be lowered, coiled and stowed.

The Reflex system consists of the Reflex cable, a continuous-line furling drum, threaded snap-shackle and soft-shackle deck fittings that screw into the base of the furler, a head swivel, and either a tack swivel for asymmetric spinnakers or a fixed tack fitting for reaching sails that have a cable in the luff. The cable, tack and head fittings remain with the sail; the tack connects to the furler’s drive spool with a slide-on T-track that’s locked in place by a spring-loaded pin.

The furlers are sold in kits. Unit 1 furlers come with a 9-millimeter cable for boats from 25 to 36 feet with a 1.5-ton maximum working load; the maximum sail area is 1,200 square feet for spinnakers and 650 square feet for code zeros. Kits start at $1,884. Unit 2 furlers, with a 13-millimeter cable, are designed for boats up to 45 feet with a maximum working load of 2.5 tons; the maximum sail area is 1,800 square feet for spinnakers and 900 square feet for code zeros. These kits start at $2,252. Additional cable and head and tack fittings can be purchased separately for those with multiple downwind headsails. The Reflex cable can also be used with other top-down furlers. The cable is easily cut using snips or a hacksaw, and clamps are included to connect end fittings. Detailed instructions and online guides make the systems easy for the do-it-yourselfer to install.

Profurl markets the Spinex line of furlers, which are developed from the company’s NEX line of furlers for straight luff sails such as code zeros. They’re designed to be purchased off the shelf at stores such as West Marine and installed by the owner without the assistance of a rigging specialist.

The Spinex furlers come with Profurl’s Sail Bearing technology, which consists of high-density spheres that spin freely around the anti-torsion cable to protect the sail from the cable. The company says the spheres also help prevent the reverse furl effect, wherein the foot of the spinnaker is sucked in while the leech is being unfurled.

“Sail Bearing technology allows you to keep the sail away from the cable, stop reverse furling that causes the sail to jam, reduce wear of the sailcloth, and make furling easier and faster because it has a greater diameter than the cable on its own,” says Profurl’s Vernon Hultzer.

The Spinex range includes four models, the Spinex .9, 1.5, 2.5 and 5.0, which are designed for boats from 16 to 60 feet with a maximum sail area of 2,690 square feet. The model number corresponds to the unit’s breaking strength in kilograms. For example, the Spinex .9 has a breaking strength of 900 kilograms (1,984 pounds), and the 5.0 has a breaking strength of 5,000 kilograms (11,023 pounds). The Spinex furler comes complete with drum, swivel, anti-torsion cable with spheres, end fittings, and tack swivel. Aside from cutting the cable to its necessary length, Spinex units are ready to be used out of the box. Prices are $2,449 for the Spinex .9, $2,999 for the 1.5, $3,949 for the 2.5, and $6,099 for the 5.0.

Ronstan offers seven different types of top-down furlers between its Generation 1 and Generation 2 lines. The Generation 2 furlers were introduced roughly two years ago, with a focus on reducing weight as well as keeping costs down by using off-the-shelf 2-to-1 attachments and snap shackles. The Generation 2 furlers are offered in Series 80, 120 and 160 models; the Generation 1 furlers are offered in Series 170R, 200, 200R and 280 units for larger and more powerful boats.

All of the Ronstan furlers (excluding the Series 60, designed for the Weta trimaran) feature all-aluminum construction on the drum and swivel. The only piece of plastic is the “gate” that holds the furling line captive in the drum.

Ronstan recommends its Generation 2 furlers for boats ranging in size from 30 to 46 feet, and its Generation 1 units for larger boats up to Mini Maxis, but the products are rated based on maximum working load. The MWL for the Series 80 is 2,090 pounds; for the series 120, it’s 3,970 pounds; and for the Series 160, it’s 6,610 pounds. Prices range from $1,395 for the Series 80 to $2,195 for the Series 120 and $4,295 for the Series 160. The prices include the furling drum with snap shackle and head swivel.

Ronstan distributes the FSE Robline GFL anti-torsion cable with its furlers at an additional cost. The cable has a 32-plait polyester cover that makes it resistant to abrasion and UV damage and prevents any core or cover slippage. The core is 12-plait Vectran fiber for the lowest stretch, and additional impregnation provides further protection against UV damage and abrasion.

Seldén’s primary top-down furler is the GX model, which is an evolution of the company’s CX model. The GX furler won the 2014 Editors’ Choice Award from Practical Sailor magazine and comes in a kit that includes a drum, halyard swivel and anti-torsion cable. The drum and halyard swivel are permanently fitted to the sail with Seldén line locks.

All of the GX’s structural parts are constructed of high-strength duplex stainless steel, which Seldén says has a 50 percent greater breaking strength than SAE 316 stainless steel. The halyard swivel has sealed steel bearings, and a rubber fender helps prevent abrasion to the mast.

Seldén manufactures four different sizes of the GX, all based on sail area. The GX 7.5 is recommended for a maximum sail area of 540 square feet, or a safe working load of 1,685 pounds; the GX 10 is rated for a sail area of 860 square feet, or a 2,250-pound safe working load; the GX 15 is for a sail area of 1,240 square feet, or a 3,375-pound safe working load; and the GX 25 is for boats with a sail area up to 2,155 square feet, or a 5,510-pound safe working load.

The suggested retail price for the four units ranges from $930 to $2,550.

Seldén also offers a double fairlead that consists of a composite bracket fitted to a 25-millimeter or 30-millimeter stanchion and a spring-loaded stainless-steel “push-and-twist” bracket. It’s easy to open to attach the furling line and just as easy to close.

Sean McNeill is a sailing writer based in Newport who’s covered pro sailing events such as the America’s Cup and Volvo Ocean Race for the past 25 years.

- More: Gear , How To , rigging , sails & rigging , sails and rigging , top-down furler

- More How To

Shaft Bearing Maintenance Tips

When the Wind Goes Light

How We Built Our Own Bulwarks

How to Keep Your Windlass Working For You

Are Cats Killing the Monohull?

Sailboat Preview: Linjett 36

Windelo 54 Named Multihull of the Year

For Sale: 2019 Lagoon 40

- Digital Edition

- Customer Service

- Privacy Policy

- Email Newsletters

- Cruising World

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

Sign up now for our WhatsApp newsletter and receive a FREE set of SVB playing cards!

Get the latest SVB news via WhatsApp!

- Spare parts

- SVB@Youtube

- My SVB Account

- Compare list

Are you missing items that you have already placed in your shopping cart? Log in to see your saved items.

- Sailing, Rigging & Deck

Sailing made easy: Everything you need to know about roller furling systems

What does a furling system on board sailing yachts do? A furling system allows you to set, recover and partially reef your foresail (genoa or jib) conveniently and practically from the cockpit. These systems are now fitted as standard on most sailing boats thanks to the ease and effectiveness of the system and greater safety when furling and setting. Find out everything there is to know about roller furling systems in this SVB guide: what they are, the main differences, features and advantages, which ones to choose, how they work and why to have them on board.

Roller Furling Systems for Sailboats

- Advantages of a furling system

- How it works

- The ideal furling system

Installation and Maintenance

- Retrofitting

- Maintenance

Ultimate sailing convenience: The advantages of roller furling systems on sailboats

The use of furling systems has undoubtedly revolutionised cruising and regatta sailing since they first became available some years ago. These practical systems allow the sail to be furled without time-consuming hoisting or lowering each time you go sailing. Using a practical furling system, the foresail can be easily furled from the cockpit, without you or your crew risking life or injury on deck, as it eliminates the need for a crewmember to manually change or reef the jib or genoa. A furling system is certainly an efficient, easy and enjoyable way to deploy or stow sails on a yacht. However, whether or not such a system is appropriate for you largely depends on the size of your vessel and the sort of sailing boat you own.

Nevertheless, the obvious benefits outweigh the disadvantages, which is why a furling system is now standard equipment on almost all sailing yachts. The convenience of not having to recover, set, change or stow your sail is a big advantage! A roller furling system minimises or eliminates the need to carry additional headsails, resulting in not only increased room below deck, but also the removal of the laborious task of lowering and removing your jib or genoa after each voyage.

Roller reefing is useful when overlapping genoas obscure visibility. By reefing the genoa a few turns you can have a clearer view ahead leeward, which shortens the sail and increases visibility - important for safety and peace of mind. A furling system allows you to reef the headsail completely or partially. This way, even if you don't have experienced crew members on board, you can still safely manoeuvre your boat and cope with any wind gusts.

Roller Furling

How does a furling system work?

Roller furling - how it works.

A roller furling system allows you to roll or wrap your foresail around the headstay. This not only makes sailing easier, but also improves safety by allowing reefing without the crew having to go on deck in bad weather. To understand how to use a roller furling system, it's first important to know how it works, what specific steps to take when using it and to observe important safety measures. Using a roller furling systems is a relatively straight forward affair, but correctly furling the staysail is not as easy as it may first seem!

The setup of a roller furling system consists of a wire, foil, or spar around which the sail is spun. This is controlled by a furling line that is pulled or released from the cockpit. The foil is actually an aluminium track, up which the sail is fed all the way to the top. At the top of the track and at the bottom, the sail is on a swivel, which allows the sail to spin out while a drum rotates. The drum takes up the extra slack from the furling line as the sail is opened by pulling gently on the sheet and is furled by pulling the furling line. It is advisable to keep slight back tension on the sail while furling by leaving one wrap of the sheet on the winch. Pull the furling line to wrap the sail tightly around the forestay/headstay. To partially furl (reef) the sail, pull the furling line until the desired size of the headsail is reached, then belay the line. The headsail can thus be continuously adjusted to any size.

During furling or unfurling you should maintain a light pull on the sheet and furling line at all times. This keeps the furling line neatly spun and unspun around the drum and reduces the risk of an "override", where the furling line binds on itself and makes further unfurling difficult. Take special care that the furling line is of the correct length. It should still be able to make about 3 to 5 turns around the drum after the sail is fully furled and pulled tight. Generally, the optimum length is between one and a half and two times the length of your boat.

Ensure that the foresail halyard maintains an angle of 5° to 10° to the forestay when the sail is set on the furling system. To ensure proper reefing system function, the halyard must not run parallel to the forestay. Pay particular attention to the specifications in the assembly instructions. Alternatively, special fairlead blocks can be installed to allow the desired angle.

If the drum of the roller furling system gets in the way of manoeuvring the anchor at the bow, it can be raised with an eye/fork extension or two stainless steel chain-plates attached via a hinge to the mainsail at the bow.

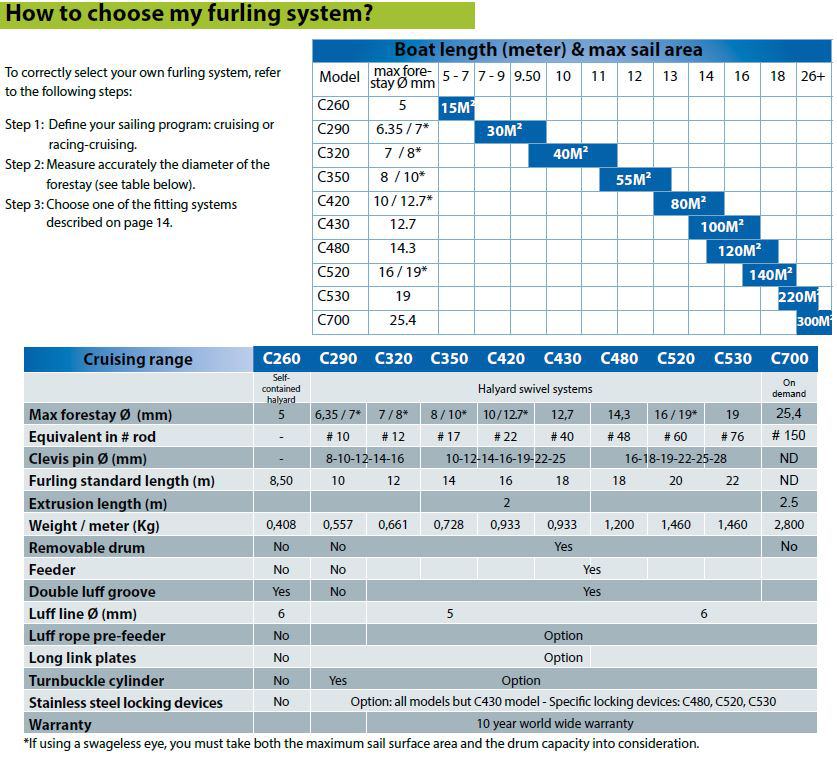

How do I choose the right roller furling system for my boat?

If you want to install a furling system on your boat, there are a few things to consider first. This includes the size and weight of your boat, the area of the headsail and the diameter and length of the forestay. In order to find the right furling system, most manufacturers offer general guidance based on a boat’s overall length and class.

Having instant control of the sail with maximum surface area, as well as the capacity to navigate larger boats with a high level of safety and control, especially while sailing solo, are strong reasons that have impressed boat owners all over the world for many years. A clear view ahead, as well as the ability to recover and set sail fast, add to the appeal of furling systems.

Roller furlers are safe and convenient, but they are also heavy systems that can inevitably cause forestay sag. If sag is too much, it will affect sailing performance, especially when the wind picks up, but also in particular when sailing upwind. In addition to adjusting the backstay, some rig types also allow the tension of the upper shrouds to be increased in order to influence the leeward slope.

How can I retrofit a roller furling system?

The first thing to do before you start to fit your roller furling system is to familiarise yourself with the installation manual. It contains detailed and illustrated instructions that will enable you to assemble a roller furling system correctly. It should be noted, however, that the assembly steps may vary depending on the model and on the profile configuration and the number of parts to be installed.

The manufacturers PROFURL , NEMO and FURLEX offer comprehensive instructions on how to install a roller furling system. Take a good look and then decide for yourself whether you think you can install the system on your own. If in doubt, please get help from friends and/or boat neighbours who have already carried out such an installation. Local sailmakers and service providers in the harbours are also happy to provide guidance and tips. Please also bear in mind that the existing headsails must be adapted to the requirements of the furling system. This work can only be carried out by a specialist company (sailmaker). Although some manufacturers allow upright mounting as an option, we always recommend that you mount your furling system in a horizontal position. Do this especially if your vessel is in winter storage, as it ensures better stability and potential loads on the mast can be reduced.

Does a furling system require regular maintenance?

Furling systems are designed to minimise the need for maintenance and servicing. Nevertheless, this does not mean that maintenance is totally unnecessary. If you want to maintain the functionality and efficiency of your furling system, regular maintenance should be carried out.

To maintain full functionality of your roller furling system, you should clean it regularly with fresh water to remove salt deposits and dust from the drum and the inside. Some roller furlers require additional lubrication during operation. Be sure to follow the instructions in the user manual.

Further reading: Roller Furling Systems, Jib Furlers and Accessories

Don't compromise on the quality of your new foresail furling system. Even if you are on a tight budget - SVB has the right product for you! Discover our selection of NEMO , PROFURL and FURLEX foresail furling systems in various sizes - all available for you to select according to boat type, forestay diameter and length. In our categories Roller Furlers, Jib Furlers & Accessories you will not only find high-quality furling systems, but also matching accessories, such as drums, swivels and profiles from brands like PFEIFFER , TOP-REFF , BARTON and OLEU WATERSPORTS all at unbeatable prices! Are you looking for individual spare parts for your FURLEX roller furling system? No problem! Check out our spare parts finder for FURLEX furling systems !

Share our guide on social media

What Is A Furler On A Sailboat?

Last Updated by

Daniel Wade

August 22, 2023

Key Takeaways

- Sailing furlers are common in a variety of different types of sailboats

- These are used to make life easier when sailing or racing to roll the sails in or out

- They are an extremely convenient tool that provides efficiency if used appropriately

- Furler sails can come in many shapes and sizes depending on the boat

- Your sailing goals may go hand in hand with the type of furler you have on board

Furler sailing is a convenient way to make life easier on your sailboat. But what is a furling system on sailboats?

Roller furling systems are unique mechanisms that allow you to effortlessly roll up the sail or unfurl. A roller furling system features a central location for a drum or spool for storing the sail and a furling line to give sailors the ability to operate the sail.

In my experience, furling systems are comparable to reefing systems, but are arguably best for moderate conditions while sailing. Depending on what setup you have will likely make a difference while sailing.

Table of contents

How Does a Roller Furling System Work?

A roller furling setup will vary depending on what type you have on your boat. Most boats today have some type of system already on board, especially racing boats.

Sailors can adjust their sail area or store their sails efficiently by pulling on the furling line. This line can be controlled from the boat's cockpit and allow solo sailing to be more manageable and eliminating the need for crew members to handle bulky sails manually.

There are a variety of positives with furlers that most sailors find useful. Below are the pros for these systems.

Ease of Use

They are convenient and make for a quick setup while adjusting to the wind in various conditions. This allows an easy transfer without having to take the sails down or changing them out completely.

Peace of Mind

This makes it safer while sailing since you will have better response times and control from the cockpit. This helps limit the likelihood of any dangers out on deck or due to weather.

You have the power in your hands to adjust for sailing power. This gives you total control of when to optimize the best sailing conditions.

Longevity in Mind

A furling system allows you to roll up the sail neatly to avoid exposure to harmful UV rays and other issues obtained if you were to leave it out. This is crucial for long term use and for protecting your investment.

There are some negatives to keep in mind for these systems as it may interfere with your sailing goals. Below are the cons to consider.

Strong Conditions

These may not operate the best in windy conditions. A furled sail could decrease upwind performance if the conditions are not the best.

Rope Could Weaken

The rope that is used to control the furler is susceptible to chaffing. This must be checked each time you are going out on the water in addition to other safety guidelines.

Location of Drum

The drum is usually installed on the deck. This means the sail area is slightly reduced and the luff is shortened.

Needs Routine Maintenance

You should always look over and keep records of maintenance on board. The bearings are one example of something you should keep an eye on as the saltwater and sand will cause wear and tear.

Different Types of Roller Furling Systems

There are different types of furling systems that you might have already or might be interested in getting. Some are easy to use while others might be difficult depending on the setup. Below are the three system setups that you will likely need to learn more about.

If you enjoy manual labor to roll the sail in or out, then this means you have a manual one. These are usually cheaper because it is more physically demanding.

You simply need to be able to push a button to get an electric furler to operate. This provides a much smoother sailing experience if you are unable to roll the furlers out by hand.

If you have a larger yacht then you might have a hydraulic furler . These are definitely smoother and offer excellent power.

Which Roller Furling is Best for You?

Now that you know some differences between manual, electric, and hydraulic, you can take a step further and see which system is best for your sailing goals. There are specific names used in the marine industry to categorize these furling systems.

This is the most basic setup for a furling system. This system includes a deck swivel drum, wire luff headsail, and head swivel. This also means you do not need hanks or the use of luff tape.

Internal Halyard

The internal halyard runs alongside the forestay without using the jib halyard. It employs an internal halyard for one groove, while the sail's luff slides up another groove, and prevents the halyard from getting tangled.

Head Swivel

The head swivel is one of the most popular systems and most expensive since it operates the smoothest out of them all. It features a lower drum, equipped with metal cross-sections, and a ball bearing head swivel. It is excellent for racing and for changing headsail easily.

Bottom or Top Down Furler

All systems back in the day were once bottom-up furlers. As engineering improved over the years, more headsails were designed for lighter wind.

The bottom is a standard roller furler where the base of the drum unrolls to release the sail. When rolled back, the sail wraps from the base and is common for jib and genoa sails.

The top down furler is for Code 0 and asymmetric spinnakers. These roll the sail from the top to the base, leaving the base free-floating and improving sail handling.

Cleaning and Maintaining Your Furler

Proper routine maintenance is crucial for keeping your boat in the best shape. This means you cannot afford to skip checking or repairing your furler.

Failure to spend a solid 15 to 30 minutes taking the time to properly clean and maintain your furler will cost you more time and money down the road. Below are a few tips to get started for most furlers.

Reading the Manual

It is imperative that you read and understand the manufacturers manual that came with the furler. This will have the basics and everything else you need to know about safe operation or properly maintaining the furler.

If you do not have one after buying a boat, then you can look for it online or contact the manufacturer to send you one. In addition, you could always look online and read forums that talk about similar issues with their furlers.

Get the Furler Ready

The first thing you should do is to remove the genoa sail and mark the furling line for easy removal of the drum during year-end maintenance or before the season starts. Check the bolts, drum, and remove any debris that could be lodged with a degreaser (your manual might recommend one).

Lube All Required Locations

If any parts move then there needs to be some kind of lubrication. This is especially true if you have metal on metal.

Your manual will likely tell you what type of grease to use and where to apply it. Once that is completed you can assemble the drum and clean everything you touched.

Related Articles

I've personally had thousands of questions about sailing and sailboats over the years. As I learn and experience sailing, and the community, I share the answers that work and make sense to me, here on Life of Sailing.

by this author

Learn About Sailboats

Most Recent

Affordable Sailboats You Can Build at Home

September 13, 2023

Best Small Sailboat Ornaments

September 12, 2023

Important Legal Info

Lifeofsailing.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon. This site also participates in other affiliate programs and is compensated for referring traffic and business to these companies.

Similar Posts

Discover the Magic of Hydrofoil Sailboats

December 11, 2023

Hunter Sailboats: Are They Built for Bluewater Cruising?

August 29, 2023

What Is Sail Roach?

August 15, 2023

Popular Posts

Best Liveaboard Catamaran Sailboats

December 28, 2023

Can a Novice Sail Around the World?

Elizabeth O'Malley

June 15, 2022

4 Best Electric Outboard Motors

How Long Did It Take The Vikings To Sail To England?

10 Best Sailboat Brands (And Why)

December 20, 2023

7 Best Places To Liveaboard A Sailboat

Get the best sailing content.

Top Rated Posts

Lifeofsailing.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon. This site also participates in other affiliate programs and is compensated for referring traffic and business to these companies. (866) 342-SAIL

© 2024 Life of Sailing Email: [email protected] Address: 11816 Inwood Rd #3024 Dallas, TX 75244 Disclaimer Privacy Policy

Practical Boat Owner

- Digital edition

Headsail furling: how to choose the right system

- Rupert Holmes

- February 14, 2023

There is a huge range of headsail furling gear on the market. Rupert Holmes gives some tips for choosing the right system for your boat

Over the last five years, headsail furling systems have been fitted as standard on new yachts. A Facnor FD in use. Credit: Rupert Holmes Credit: Rupert Holmes

Headsail furling systems are ubiquitous, yet anyone who has to replace a damaged or worn-out system is faced with a bewildering range of options.

Granted, you could opt for the nearest like-for-like replacement, on the basis perhaps that there’s not likely to be much wrong with a system that has lasted for 20, 30 or even 40 years.

However, that may mean you’re buying a more expensive system than necessary.

Partially reefed genoa with poor sail shape. Credit: Rupert Holmes

For example there’s little point in paying a premium solely to get a double luff groove and removable drum if you never race fully crewed.

Having said that, twin grooves may be useful for setting twin poled out headsail s for cruisers intending to cross the Atlantic .

Equally, automatically choosing a like-for-like replacement may mean you miss out on more recent developments that can improve sail shape and reliability.

Recent headsail furling developments

One of the more interesting of these is the Facnor FD (flat deck) that uses webbing at the drum rather than rope .

This allows for a lower-profile drum that increases the luff length of the sail, making it more efficient.

It also increases the mechanical advantage (ie leverage) when you first start furling, so the operation requires less effort.

The way the webbing leads onto the drum all but eliminates the risk of over-riding turns if the sail is unfurled too fast.

Yet at the cockpit end you handle a rope of a comfortable diameter, as with any other system.

This Facnor FD swivel joins the webbing to the rope that’s used to handle the furling line in the cockpit. Credit: Rupert Holmes

And the Torlon bearings require no maintenance other than regular rinses with fresh water.

These benefits mean that over the past five or six years it has become standard fit on many new yachts, particularly in the performance cruising sector.

Having used one myself for the past six years the only downside I’ve found is the need to replace the furling tape – usually every two or three years.

Seldén’s Furlex systems are well proven and, like the Facnor FD, start by taking bulk out of the middle of the sail, which helps improve shape when it’s part reefed.

Facnor FD uses webbing to furl rather than rope

The fourth generation version is 8% lighter, reducing weight aloft, and comes in five sizes for boats from 18ft up to 30 tonnes displacement.

It’s also available in electric and hydraulic models and with a below-deck drum.

Harken’s systems for boats from 22-80ft are also now in their fourth generation and feature large, low friction bearings along with independent tack and head swivels that allow the middle of the luff to furl first for an improved sail shape.

The company has recently added Ocean furlers to the range, which have a single groove round foil that makes for easier furling at the expense of a marginal aerodynamic loss when the sail is fully unfurled.

Ocean units also have a fixed tack swivel and drum that cannot be removed for racing.

Continues below…

How to set up your rig: tension your shrouds on masthead or fractional

How to set up your rig: tension your shrouds on masthead or fractional If boats were cars, many of those…

How to check your rigging

Maintenance of your rigging can save expensive failures and could be a lifesaver - here's how to check your boat's…

How to reef – expert advice from PBO Sail Clinic

How do you ensure an efficient reef with a roller-reefing headsail and slab-reefing mainsail? David Harding explains

Why won’t my boat tack properly?

David Harding offers ideas to help a Kelt 5.50 that won't beat upwind

I’ve also used Plastimo’s units, which have proved reliable over many years and can make a good budget option.

They are available in three sizes to suit boats from 14-36ft, with the largest retailing at well under £1,000.

However good your furling gear, it’s no secret that a deep reefed genoa will tend to set with a very inefficient shape.

Latest generation of Seldén’s Furlex 304S for boats up to 15 tonnes displacement

By the time a 130% or 140% overlapping headsail has been reefed down for strong winds a lot of the luff length is lost, which markedly reduces the sail’s efficiency.

In addition, the typical heavy UV strip on the luff and leech mean these areas gather bulk fastest as the sail is progressively reefed further and further.

This leads to a very deep shape in the middle of the luff, which leads to excessive heeling and weather helm .

Of course the effect can be reduced to some extent with foam (or rope) luff padding, furling systems that roll the centre of the sail first, and high tech sails with minimal stretch, but even then it can’t be eliminated in a deep reefed sail.

Twin forestays

Large bluewater yachts, typically those over 45ft, often have twin forestays with a genoa on the outer one and a smaller, higher aspect non-overlapping jib on the inner, with both set on roller furling gear.

This is an excellent arrangement that gives a large sail for light airs and reaching, plus one that will set efficiently in stronger winds and that’s easy to sheet in when short tacking.

Some new smaller performance cruisers have a similar arrangement, but use a free-flying furling sail on a halyard lock instead.

This means it can be rigged easily when needed, but is out of the way for the rest of the time.

Headsail furling gear for smaller boats: Plastimo 609 for boats from 20-30ft

Both these options would be clunky and expensive to retrofit on a smaller boat, but it’s relatively easy and inexpensive to replicate a similar set up using a removable Dyneema inner forestay.

Seldén sells a sensibly priced fitting for the mast for exactly this purpose.

The loads at the deck end of such a system should not be underestimated – on a 35ft boat a safe working load of several tonnes may be needed.

Therefore, simply bolting a fitting through the deck won’t suffice.

If you’re lucky enough to have a suitable bulkhead just back from the main forestay that can be used for a chainplate.

Alternatively, the deck fitting can be tied down to a fitting on the stem and tensioned using a bottlescrew or suitable purchase system.

Seldén’s Inner forestay fitting can be used with existing spars

There are two options for tensioning the stay on deck.

The neatest and cheapest is to take a 2:1 purchase back to a coachroof winch.

This also has the advantage of making it easy to set the inner forestay up at sea and the jib can be hanked on in advance so that it’s ready for use.

The other route is a large Highfield lever or adjustable bottlescrew – Seasure and Wichard respectively both have products for this purpose.

However, these can be difficult to fit when the boat is pitching in waves, so are best set up before leaving port on a breezy day.

This stay can be used for a hanked-on heavy weather jib (the size of a J3 or J4), or a storm jib.

If having a new sail made, it’s worth specifying it with extra reinforcement and a slab reef, which makes it easy to change down to a storm jib size sail without going onto the foredeck.

Enjoyed reading Headsail furling: how to choose the right system?

A subscription to Practical Boat Owner magazine costs around 40% less than the cover price .

Print and digital editions are available through Magazines Direct – where you can also find the latest deals .

PBO is packed with information to help you get the most from boat ownership – whether sail or power.

- Take your DIY skills to the next level with trusted advice on boat maintenance and repairs

- Impartial in-depth gear reviews

- Practical cruising tips for making the most of your time afloat

Follow us on Facebook , Instagram and Twitter

Top Down Furlers

The latest buzz in the furler world is the top down furler, a great way to handle the spinnaker short-handed. Also called a “loose” luffed furler, it can be added to an existing spinnaker to roll up for hoisting, dousing, and controlled jibing.

Top down furlers have found their way onto everything from large mega yachts to shorthanded offshore racing boats. It is a great solution for handling a large headsail, and typically easier than a sock.

A top down furler drives a torsion rope that rotates and gathers the sail from the top, and it continues to wrap downward. It leaves the sailor with a nice, tight, wrapped sail that is easy to handle.

There are many variations of torsion ropes and furling lines, as well as full units, and prices vary. Let us help you pick the right equipment, or explore Top Down Furlers at the Rigworks Online Store »

Here is a comparison sheet provided by Ronstan.

historical leader of furling systems.

Find out our product ranges dedicated to furling, our technical documentation and get access to our nearest resellers.

Our product ranges

Manual reefing systems, motorized headsail furlers, motorized flying sail furlers, stayfurlers, swivel locks, find a reseller, the experts' blog.

10 reasons why Profurl manual headsail furler comes with a 10-year guarantee

With more than 40 years of French furling systems expertise behind us, Profurl is no newcomer to the game: pleasure sailors, regatta specialists, circumnavigators and professionals alike put their faith in the brand,…

The right way to winterize your boat

Winter is a transition period for many sailors, a time marked by storms, low temperatures and short days. Long hours spent on the water give way to quick trips on deck, preparing your beloved so she will be ready for…

New NEXeLITE 6.5 - motorized flying sail furler

NEXeLITE 6.5. Designed for furling flying sails up to 250 sqm, this new model brings comfort and fast operations. It’s the ideal solution for short-handed crews and solo navigation. The NEXeLITE 6.5 will allow you to…

Subscribe to our newsletter

To follow our latest news and novelties

The #profurl community

Currency: GBP

- Worldwide Delivery

Mooring Warps and Mooring Lines

- LIROS 3 Strand Polyester Mooring Warps

- LIROS Green Wave 3 Strand Mooring Warps

- LIROS Braided Dockline Mooring Warps

- LIROS Handy Elastic Mooring Warps

- Marlow Blue Ocean Dockline

- LIROS Super Yacht Mooring Polyester Docklines

- 50 metre / 100 metre Rates - Mooring

Mooring Accessories

- Mooring Compensators

Mooring Strops and Bridles

- V shape Mooring Bridles

- Y shape Mooring Bridles

- Small Boat and RIB Mooring Strops

- Mooring Strops

- Mooring Strops with Chain Centre Section

Mooring Assistance

- Coastline Bow Thruster Accessories

- Max Power Bow Thrusters

- Bonomi Mooring Cleats

- Majoni Fenders

- Polyform Norway Fenders

- Ocean Inflatable Fenders

- Dock Fenders

- Fender Ropes and Accessories

Mooring Components

- Mooring Swivels

- Mooring Shackles

- Mooring Cleats and Fairleads

- Mooring Buoys

Mooring Information

- Mooring Warps Size Guide

- Mooring Lines - LIROS Recommended Diameters

- Mooring Rope Selection Guide

- Mooring Warp Length and Configuration Guide

- How to estimate the length of a single line Mooring Strop

- Mooring Ropes - Break Load Chart

- Mooring Compensator Advisory

- Rope Cockling Information

- Fender Size Guide

- Majoni Fender Guide

- Polyform Norway Fender Inflation Guide

- More Article and Guides >

Anchor Warps Spliced to Chain

- LIROS 3 Strand Nylon Spliced to Chain

- LIROS Anchorplait Nylon Spliced to Chain

Anchor Warps

- LIROS Anchorplait Nylon Anchor Warps

- LIROS 3 Strand Nylon Anchor Warps

- Leaded Anchor Warp

- Drogue Warps and Bridles

- 50 / 100 metre Rates - Anchoring

- Aluminium Anchors

- Galvanised Anchors

- Stainless Steel Anchors

Calibrated Anchor Chain

- Cromox G6 Stainless Steel Chain

- G4 Calibrated Stainless Steel Anchor Chain

- Lofrans Grade 40

- MF DAMS Grade 70

- MF Grade 40

- Titan Grade 43

- Lewmar Windlasses

- Lofrans Windlasses

- Maxwell Windlasses

- Quick Windlasses

- Windlass Accessories and Spares

Chain Snubbers

- Chain Hooks, Grabs and Grippers

- Chain Snubbing Bridles

- Chain Snubbing Strops

Anchoring Accessories

- Anchor Connectors

- Anchor Trip Hooks and Rings

- Anchoring Shackles

- Bow Rollers and Fittings

- Chain and Anchor Stoppers

- Chain Links and Markers

Anchoring Information

- How To Choose A Main Anchor

- Anchoring System Assessment

- Anchor Chain and Rope Size Guide

- The Jimmy Green Guide to the Best Anchor Ropes

- What Size Anchor Do I Need?

- Anchor to Chain Connection Guide

- How to Choose Your Anchor Chain

- How to Establish the Correct Anchor Chain Calibration?

- Calibrated Anchor Chain - General Information

- Calibrated Anchor Chain Quality Control

- Calibrated Chain - Break Load and Weight Guide

- Galvanising - Managing Performance and Endurance expectation

- Can Galvanised Steel be used with Stainless Steel?

- Windlass Selection Guide

- More Articles and Guides

Stainless Steel Wire Rigging and Wire Rope

- 1x19 Wire Rigging

- 50 / 100 metre Rates - Wire and Fibre

- 7x19 Flexible Wire Rigging

- Compacted Strand Wire Rigging

Dinghy Rigging

- Stainless Steel Dinghy Rigging

- Dinghy Rigging Fittings

Fibre Rigging

- LIROS D-Pro Static Rigging

- LIROS D-Pro-XTR Fibre Rigging

- DynIce Dux Fibre Rigging

- Fibre Rigging Fittings

Wire Terminals

- Cones, Formers, Wedges, Ferrules, Rigging Spares

- Hi-Mod Swageless Terminals

- Sta-Lok Swageless Terminals

- Swage Terminals

Wire Rigging Fittings

- Turnbuckle Components

Rigging Accessories

- Rigging Chafe Protection

- Headsail Reefing Furlers

- Plastimo Jib Reefing

- Selden Furlex Reefing Gear

Furling Systems

- Anti-torsion Stays

- Straight Luff Furlers

- Top Down Furlers

Guard Wires, Rails and Fittings

- Guard Rail Fittings

- Guard Rails in Fibre and Webbing

- Guard Wire Accessories

- Guard Wires

Standing Rigging Assistance

- Replacing your Furling Line

- Fibre Rigging Break Load Comparison Guide

- More Articles and Guides >

- Cruising Halyards

- Performance Halyards

- Dinghy Halyards

Rigging Shackles

- Captive and Key Pin Shackles

- hamma™ Snap Shackles

- Soft Shackles

- Standard Snap Shackles

- Wichard Snap Shackles

Classic Ropes

- Classic Control Lines

- Classic Halyards

- Classic Sheets

- Cruising Sheets

- Performance Sheets

- Dinghy Sheets

Sail Handling

- Boom Brakes and Preventers

- Lazy Jack Sail Handling

- Rodkickers, Boomstruts

- Sail Handling Accessories

50 / 100 metre Rates - Running Rigging

- 50 / 100 metres - Cruising Ropes

- 50 / 100 metres - Dinghy Ropes

- 50 / 100 metres - Performance Ropes

Control Lines

- Cruising Control Lines

- Performance Control Lines

- Dinghy Control Lines

- Continuous Control Lines

Running Rigging Accessories

- Anti-Chafe Rope Protection

- Lashing, Lacing and Lanyards

- Mast and Boom Fittings

- Rope Stowage

- Sail Ties and Sail Stowage

- Shock Cord and Fittings

- LIROS Ropes

- Marlow Ropes

Running Rigging Resources

- Running Rigging Rope Fibres and Construction Explained

- How to Select a Suitable Halyard Rope

- How to select Sheets and Guys

- Dyneema Rope - Cruising and Racing Comparison

- Dinghy Rope Selection Guide

- Rope Measurement Information

- Running Rigging - LIROS Recommended Line Diameters

- Running Rigging Break Load Comparison Chart

- Colour Coding for Running Rigging

- Selecting the right type of block, plain, roller or ball bearing

- Recycling Rope

- Running Rigging Glossary

Plain Bearing Blocks

- Barton Blocks

- Harken Element Blocks

- Low Friction Rings

- Selden Yacht Blocks

- Wichard MXEvo Blocks

- Wooden Yacht Blocks

Control Systems

- Ratchet Blocks

- Stanchion Blocks and Fairleads

- Snatch Blocks

- Genoa Car Systems

- Traveller Systems

- Block and Tackle Purchase Systems

Ball Bearing Blocks

- Harken Ball Bearing Blocks

- Selden Ball Bearing Blocks

Roller Bearing Blocks

- Harken Black Magic Blocks

- Selden Roller Bearing Blocks

Deck Fittings

- Bungs and Hatches

- Bushes and Fairleads

- Deck Eyes, Straps and Hooks

- Pad Eyes, U Bolts and Eye Bolts

- Pintles and Gudgeons

- Tiller Extensions and Joints

- Harken Winches, Handles and Accessories

- Barton Winches, Snubbers and Winchers

- Lewmar Winches, Handles and Accessories

- Winch Servicing and Accessories

Clutches and Organisers

- Barton Clutches and Organisers

- Spinlock Clutches and Organisers

- Lewmar Clutches

- Harken Ball Bearing Cam Cleats

- Barton K Cam Cleats

Deck Hardware Support

- Blocks and Pulleys Selection Guide

- Barton High Load Eyes

- Dyneema Low Friction Rings Comparison

- Seldén Block Selection Guide

- Barton Track Selection Guide

- Barton Traveller Systems Selection Guide

- Harken Winch Selection Guide

- Karver Winch Comparison Chart

- Lewmar Winch Selection Guide - PDF

- Winch Servicing Guide

Sailing Flags

- Courtesy Flags

- Red Ensigns

- Blue Ensigns

- Signal Code Flags

- Flag Staffs and Sockets

- Flag Accessories

- Flag Making and Repair

- Webbing only

- Webbing Soft Shackles

- Webbing Restraint Straps

- Webbing Sail Ties

- Sail Sewing

- PROtect Tape

Fixings and Fastenings

- Screws, Bolts, Nuts and Washers

- Monel Rivets

Hatches and Portlights

- Lewmar Hatches

- Lewmar Portlights

- Fids and Tools

- Knives and Scissors

General Chandlery

- Carabiners and Hooks

- Antifouling

Flag Articles

- Flag Size Guide

- Bending and Hoisting Methods for Sailing Flags

- Courtesy Flags Identification, Labelling and Stowage

- Courtesy Flag Map

- Flag Etiquette and Information

- Glossary of Flag Terms and Parts of a Flag

- Making and Repairing Flags

- Signal Code Message Definitions

Other Chandlery Articles

- Anchorplait Splicing Instructions

- Antifoul Coverage Information

- Hawk Wind Indicator Selection Guide

- Petersen Stainless - Upset Forging Information

- Speedy Stitcher Sewing Instructions

- Thimble Dimensions and Compatible Shackles

Jackstays and Jacklines

- Webbing Jackstays

- Stainless Steel Wire Jackstay Lifelines

- Fibre Jackstay Lifelines

- Jackstay and Lifeline Accessories

Lifejackets

- Crewsaver Lifejackets

- Seago Lifejackets

- Spinlock Lifejackets

- Children's Life Jackets

- Buoyancy Aids

Floating Rope

- LIROS Multifilament White Polypropylene

- LIROS Yellow Floating Safety Rope

Guard Wires, Guardrails and Guardrail Webbing

Lifejacket accessories.

- Lifejacket Lights

- Lifejacket Rearming Kits

- Lifejacket Spray Hoods

- Safety Lines

Seago Liferafts

- Grab Bag Contents

- Grab Bags and Polybottles

- Liferaft Accessories

- Danbuoy Accessories

- Jimmy Green Danbuoys

- Jonbuoy Danbuoys

- Seago Danbuoys

Overboard Recovery

- Lifebuoy Accessories

- Purchase Systems

- Slings and Throwlines

Safety Accessories

- Fire Safety

- Sea Anchors and Drogues

Safety Resources

- Guard Wires - Inspection and Replacement Guidance

- Guard Wire Stud Terminal Dimensions

- Webbing Jackstays Guidance

- Webbing Jackstays - Custom Build Instructions

- Danbuoy Selection Guide

- Danbuoy Instructions - 3 piece Telescopic - Offshore

- Liferaft Selection Guide

- Liferaft Servicing

- Man Overboard Equipment - World Sailing Compliance

- Marine Safety Information Links

- Safety Marine Equipment List for UK Pleasure Vessels

Sailing Clothing

- Sailing Jackets

- Sailing Trousers

- Thermal Layers

Leisure Wear

- Accessories

- Rain Jackets

- Sweatshirts

Sailing Footwear

- Dinghy Boots and Shoes

- Sailing Wellies

Leisure Footwear

- Walking Shoes

Sailing Accessories

- Sailing Bags and Holdalls

- Sailing Gloves

- Sailing Kneepads

Clothing Clearance

Clothing guide.

- What to wear Sailing

- Helly Hansen Mens Jacket and Pant Size Guide

- Helly Hansen Womens Sailing Jacket and Pant Size Guide

- Lazy Jacks Mens and Womens Size Charts

- Musto Men's and Women's Size Charts

- Old Guys Rule Size Guide

- Sailing Gloves Size Guides

- Weird Fish Clothing Size Charts

The Jimmy Green Clothing Store

Lower Fore St, Beer, East Devon, EX12 3EG

- Adria Bandiere

- Anchor Marine

- Anchor Right

- August Race

- Barton Marine

- Blue Performance

- Brierley Lifting

- Brook International

- Brookes & Adams

- Captain Currey

- Chaineries Limousines

- Coastline Technology

- Colligo Marine

- Cyclops Marine

- Douglas Marine

- Ecoworks Marine

- Exposure OLAS

- Fire Safety Stick

- Fortress Marine Anchors

- Hawk Marine Products

- Helly Hansen

- International

- Jimmy Green Marine

- Maillon Rapide

- Mantus Marine

- Marling Leek

- Meridian Zero

- MF Catenificio

- Ocean Fenders

- Ocean Safety

- Old Guys Rule

- Petersen Stainless

- Polyform Norway

- PSP Marine Tape

- Sidermarine

- Stewart Manufacturing Inc

- Team McLube

- Technical Marine Supplies

- Titan Marine (CMP)

- Ultramarine

- Waterline Design

- William Hackett

Clearance August Race Boat Cleaning Kit £26.00

Clearance LIROS Racer Dyneema £55.08

Clearance Folding Stock Anchor £123.25

Clearance LIROS Herkules £0.00

Clearance Barton Size 0 Ball Bearing Blocks - 5mm £0.00

Clearance Marlow Blue Ocean® Doublebraid £18.48

Mooring Clearance

Anchoring clearance, standing rigging clearance, running rigging clearance, deck hardware clearance, chandlery clearance, safety clearance.

Profurl design and manufacture a comprehensive range of Manual Reefing Systems for Flat Heasails i.e. Jibs, Genoas and Yankees for cruising and racing.

The Jimmy Green Rigging Sales Team are available to help you select the correct system for your individual yacht and your anticipated sailing requirements.

Cruising models are available for yachts between 5 and 26 metres. They feature a round profile, silver, anodised, double luff groove foil. Racing models are offered for yachts between 6 and 20 metres. They feature an aero shaped, black, anodised, double luff groove foil.

PROFURL have decades of experience in producing Headsail Reefing Systems for Cruising and Racing Yachts. The first furling system was launched in 1980 and Profurl quickly became a technological pioneer as well as the worldwide market leader in the field of Furling Gear.

PROFURL has been part of Wichard, the world famous French marine hardware manufacturer since 2002 – Profurl is manufactured under the Wichard umbrella in France guaranteeing quality and peace of mind

Research and Development is an important factor in the continuing quality and reliability of Profurl Reefing.

All Profurl products are designed and tested by the Profurl team of highly skilled engineers, assisted by the latest computer tools and software, based in Pornichet on the west coast of France.

PROFURL products are submitted to a range of scientific tests in order to test their resistance, beyond what could actually be experienced on a yacht. They are then developed and honed to perfection with the help of feedback from the world’s most respected riggers, sail makers and sailors

The Profurl Manufacturing Process is meticulous

- The raw materials are carefully selected

- The specifications are finalised with a view to extensive and rigorous use

- The mechanical parts are machined using a controlled patented process

- The extrusions are produced from alloy of the purest metallurgical quality