Complete SCAMP building plans. Eight detailed 24 x 36" printed plans sheets plus the detailed spiral-bound SCAMP Builders Manual. Welcome aboard!

SCAMP Building Plans

Campy's "WICKED BEAT"

All days should be like today!

Friday, February 1, 2019

Building scamp, an 11 foot long, wood sailboat..

Keep us all up to date with picture's. Sounds like fun...

Post a Comment

Small Craft Advisor

Boat Designs: Evaluating SCAMP’S Big Sister

(this new welsford cruiser checks a lot of boxes…).

Over the past few days I’ve had email exchanges with John Welsford, New Zealand designer, regarding a brainstorm that’s been percolating in his clever, whimsical noggin: A bigger, more commodious takeoff on his wildly popular SCAMP design.

As most SCA readers know, the 11’ 11” SCAMP design was conceived 13 years ago when Josh Colvin, editor of this fine publication, asked Welsford to come up with a new kind of small cruising boat—one small enough to explore the most hard-to-penetrate backwaters, while being easy to rig, light enough to trailer with the smallest of tow vehicles, surprisingly great under sail, and comfy for overnight camp-cruising adventures. So, following some tweaks by designer and master boatbuilder Kees Prins, the resulting sailboat was dubbed SCAMP, for Small Craft Advisor Magazine Project.

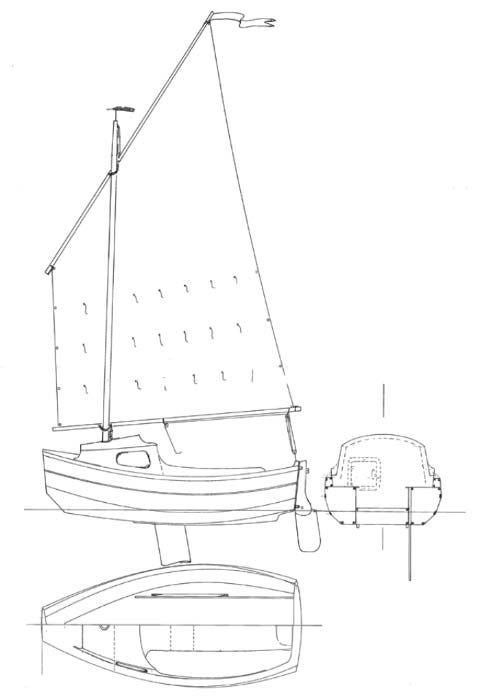

SCAMP DRAWING…

The rest is history: More building plans and kits for SCAMP have been sold over the years than any other small cruising boat we can think of. Besides the original wooden version, Gig Harbor Boat Works was licensed in 2013 to produce a fiberglass SCAMP, and the little giant killer—in wood and fiberglass—has since its debut been at the center of various small-boat rallies, workshops and sailing events.

While SCAMPs are still being built worldwide by enthusiasts, plan and kit sales have slowly been approaching what might be a kind of saturation point. It’s not that “everyone who wants a SCAMP has already built one,” but we get the feeling that it’s time for something new and different—like a SCAMP-inspired design that has the personality and quirky appeal of the original boat, but with more creature comforts (for an aging population of SCAMP lovers).

Meet SCALLYWAG, John Welsford’s big sister to SCAMP, a 15’ 4” x 7’ 3” wonder with a “real” cabin, tabernacle mast, mizzen sail, powerful main, water-ballast tanks, sitting headroom down below…and like SCAMP, faster than many onlookers might expect.

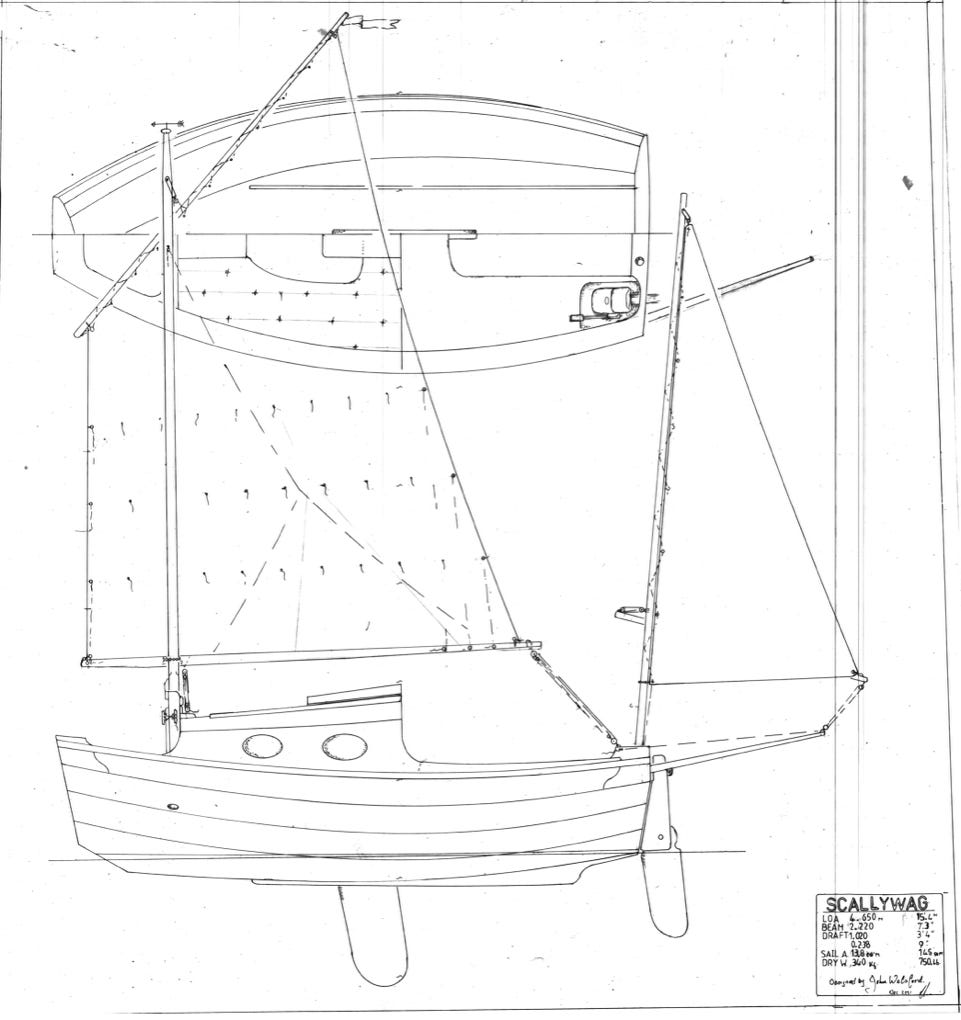

SCALLYWAG DRAWING…

This might turn out to be a timely, common-sense follow-up to the successful SCAMP design—so tempting that John Welsford is talking about building one for himself.

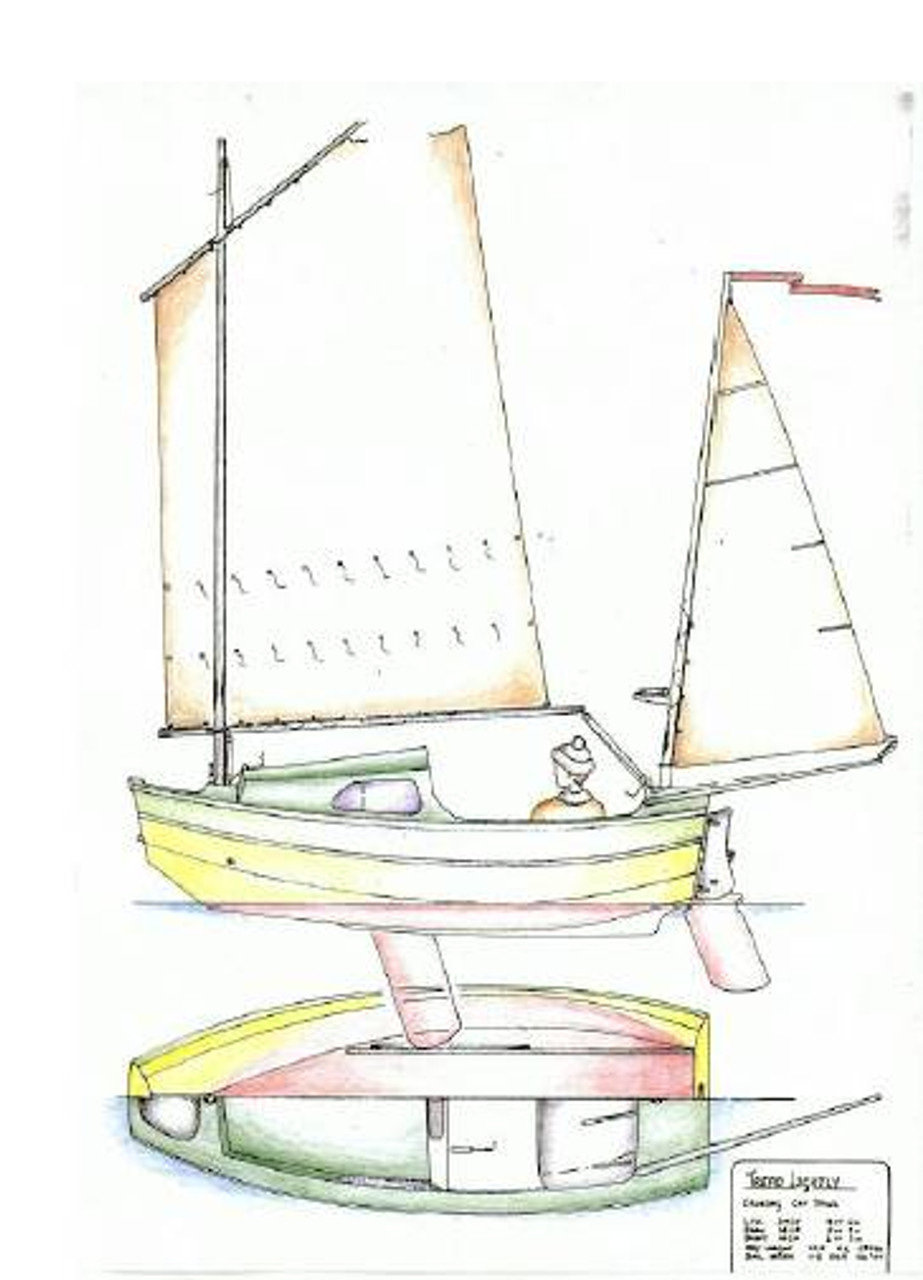

(As a footnote, we might add that in 2008, prior to the introduction of SCAMP in 2010, Welsford came up with another design that was similar to but somewhat larger than SCAMP—called TREAD LIGHTLY, which measured 13’ overall, with a beam of 5’ and addition of a mizzen. The series of similar hulls began with PEANUTS, an experimental build that never quite made the plans list. That design led to TENDER BEHIND, then SHERPA, then TREAD LIGHTLY, then SCAMP, then SCRAPS and now SCALLYWAG. Quite a series!)

TREAD LIGHTLY drawing…immediate predecessor to SCAMP)

Here is John Welsford’s description of the SCALLYWAG design:

“I’ve had a number of people tell me they love SCAMP, but they’d like a ‘real’ cabin—something that would provide shelter for a couple of friends to overnight out of the rain; somewhere with space enough for four to sit and chat over coffee or rum on a cold evening; somewhere with a bench for a cooker, a table to eat the food off of, and lockers for all the essentials…and room for the skipper and first mate to stretch out and sleep in comfort.

“SCALLYWAG is not so big as to make launching and retrieving a chore; her mainmast is in a tabernacle, which makes standing it up easy-peasy for clients who don’t like the idea of lifting a mast that size vertically into place. Her mizzen is light enough to not be a worry, too, in that respect.

“The rig is a powerful one, but easy to access for reefing, and she will heave to under mizzen with the main let free so she sits mostly head-to-wind, dry and restful if a gust has to be waited out.

“I’ve added a pair of big water tanks for ballast, so with that and her beamy shape she’ll be very stable. Her cockpit self-drains, the motor is inside the tall transom for easy access, and while there’s room in the cockpit for four, she’ll be easy to single-hand and relaxing to sail.

“While the relationship between SCALLYWAG and SCAMP is obvious, it’s not just the styling. The backroom calculations in hydrodynamics suggest she’ll handle well, and be faster than many expect. With high stability and the ability to sit upright when aground, she’ll be able to transition from hiding in the mud or sand up a creek somewhere, to making a longer coastal passage without any fuss.

“Construction is simply plywood over ply bulkheads, with stringers to line everything up, and with considerable buoyancy just in case. The plans will have scale drawings of all major components, and we anticipate soon having printable full-sized templates for frames and other key items.”

As for specifications, beyond the overall length of 15’ 4” and beam of 7’ 3,” SCALLYWAG will have board-up draft of 10,” a board-down draft of 3’ 4,” a total sail area of 143 s.f. and a fully-rigged dry weight of 750 lbs. (Incidentally, the beam-to-length ratios of SCAMP and SCALLYWAG are almost identical.)

John Welsford says that plans for SCALLYWAG will be available on December 1, but he can take orders in the meantime. Price will be $245 U.S. funds for emailed, printable PDFs, and the plans can be ordered via John’s website: jwboatdesigns.co.nz (Joel Bergen, well-known for the Welsford Navigator he built and sails in many Northwest small-boat events, will be developing a set of SCALLYWAG patterns in the not-distant future, according to Welsford. Editor’s note: We heard from Joel yesterday; he’s hoping to develop CAD-produced patterns “in a few weeks,” now that he’s received initial SCALLYWAG drawings. Stay tuned; we’ll provide updates on plans and patterns in this space.)

FIRST IMPRESSIONS OF THE SCALLYWAG DESIGN:

Eager to hear what SCAMP-savvy friends might have to say about the SCALLYWAG specs and just-released drawing, we sought initial reactions from…

JOSH COLVIN, editor of Small Craft Advisor , who commissioned the SCAMP design in 2010 and enjoys sailing SCAMP #1:

“There’s certainly no doubt who designed this one! It looks almost as much like Welsford’s PENGUIN as a SCAMP. SCALLYWAG’s length is a sweet spot in terms of accommodations potential. She’ll be rowed less than most SCAMPs, but I love the inboard motor well to keep her lines clean, and the engine right at hand. But her most exciting feature is the addition of the mizzen, which will improve seaworthiness and make managing the mainsail easier.

“Between LONG STEPS and SCALLYWAG, those looking for something like SCAMP, but larger, have great options. I’m excited to see the first boat built—she will be bigger than most expect, just looking at the drawing.” SIMEON BALDWIN, builder of an early SCAMP who has perhaps sailed more nautical miles with a SCAMP than anyone…and who has also served as a generous advisor to fellow SCAMP builders and is an expert on rigging and sailing the little 11’ 11” boats:

“I like what I see of this long-rumored design. Knowing John and his attention to ergonomics, I can anticipate it will work well. The tabernacled mast and addition of a mizzen are most appealing.

“From the drawing I think it may resemble LONG STEPS in terms of the recessed footwell. It also appears he is eschewing a by-design lazarette made popular by many SCAMP owners.

“The double water tanks are something to contemplate. I don’t envision SCALLYWAG as a purpose-built racer with crew, actively keeping high-side ballast on long tacks, like the SKATE 15 that Brandon Davis designed, which utilizes two tanks and a dump-valve system that may be more elaborate than a typical cruising sailor would want to live with. But John may be describing two water tanks that are filled and remain separate from one another.”

(Editor’s note: Welsford’s comment on tanks, “The ballast tanks are linked, and they’re not far enough off the centerline to work independently. There is one each side of the aft end of the centerboard case and they go out as far as the seat-front extensions.”)

“I’m looking forward to how all of this works out!”

BRANDON DAVIS, of Turn Point Design in Port Townsend, whose company cuts CNC kits for the SCAMP and a variety of other small boats. Brandon is also a skilled designer and small-boat sailor:

“I really like this boat, since it has just enough room to have a cabin but it’s still small enough to be trailered, beached and easily built in a garage. The enclosed cabin should encourage longer trips or taking a friend along.

“The longer waterline should increase average sailing speeds. My guess is that rowing speed will be lower than the SCAMP, as the rower will not be able to take advantage of the waterline length because of her weight.

“Will SCALLYWAG be offered as a kit? I could see it selling well as a kit and the market could be ripe. Many SCAMP builders might consider this as their next build.

“I look forward to seeing the first SCALLYWAGs on the water!”

KEES PRINS, designer and boatbuilder, who constructed the first SCAMP while serving as boatshop manager at the Northwest Maritime Center…and in the process suggested and implemented some changes that improved the design:

“I think SCALLYWAG will find a great following in the SCAMP world and beyond. Adding a cabin will greatly enlarge the ‘SCAMP Crowd.’ At that beam, and with twin ballast tanks, stability should be enormous for a boat this length. I would have liked to see a cross section through the cabin to know more about sitting comfort. (Four people hanging out inside seems a little optimistic, but two should be comfortable.)

“I’m curious about what the tabernacle for the unsupported mast will look like. A big sail area, together with a stiff hull will induce a significant load on the tabernacle. There seems to be a deep well for the mast base to swing through, judging by the drain hole.

“All in all, SCALLYWAG looks very promising.”

OSCAR LIND, a serious student of all various small-boat designs , and earlier builder of a SCAMP, who shares at least one thing in common with John Welsford—they’ve never met a pun they didn’t like:

“I might have to clear out the shop and make as much room as possible to build this boat (due to the 7’ 3” beam, especially). It’s so tempting and fills the bill for usability and function.

“It does need a Chinese lug rig, though. I expect quite a few SCALLYWAGS will ultimately be built.”

(Editor’s note: John Welsford comments, “I like the Chinese lugsail, but for a sail of this size on a boat that will be trailered, rigged and derigged for each outing and dry-stored, the extra complexity of the Junk sail slows the process. As well, the balanced lug is in my experience, a little quicker upwind—unless the junk rig has cambered-panel sails, and there are few sailmakers producing those, so I think in this case, simplicity and performance get the nod.”)

As for my personal view as a serial boatbuilder, restorer and sometimes buyer of project boats, I enjoyed owning a SCAMP several years ago. While I loved sailing the boat, I wished it was bigger and included a sleeping cabin. So, John’s new SCALLYWAG design checks many more boxes as an all-around keeper, and I prefer its overall hull, cabin and rig design, not to mention its potential as a serious cruising machine.

So, once again, here’s a chance for you, as a fellow boat nut, to offer your evaluation of SCAMP and her newly-hatched big sister, SCALLYWAG. (Also, please add other thoughts in the comments section below…) • SCA •

Discussion about this post

| · Liked by Joshua Colvin, Marty Loken

|

| Liked by Marty Loken

|

Ready for more?

Call Us: (253) 851-2126 Mon-Fri 9-5 Pacific Time

- 12′ Scamp

“I have to say it’s the biggest little boat I’ve ever sailed.”

– 48 north magazine.

The Scamp is a seaworthy 12′ sailboat that can handle a good dose of adventure.

Just under 12 feet in length, Scamp boasts an unusual combination of features that give her the unique ability to explore waters too shallow for a larger boat, while retaining most of the bigger boat’s comforts and capabilities. An offset centerboard opens up the cockpit and an 8′ 3″ sleeping area, and 172 pounds of water ballast provide exceptional stability. The cockpit is self-bailing, and a pair of grounding skegs on her flat bottom keep Scamp perfectly upright when landing on a beach or when the tide goes out.

Originally designed as a wood boat by John Welsford, Gig Harbor Boat Works worked closely with the designer and staff from Small Craft Advisor to create a fiberglass version. Scamp #1 hit the water for its first sea trial in July of 2013!

As a specialized boat, the Scamp has some different options than the rest of our boats. We have had quite a few questions about Scamp’s option list so I thought it best to go into more detail below about the various choices. Be sure to check out the “Scamp Options” tab below for photos and descriptions of all the available options.

I’d like to emphasize the fact that we build and sell all of our boats complete, ready to sail. Our “basic’” Scamp is sail ready with exactly the same top quality parts and materials as a “fancy” Scamp — you don’t have to add anything to go for a satisfactory sail. Our ‘Base’ boat’s level of completion is the same as specified in the Scamp plans or kit for DIY home builders. Options are exactly that… individual choices made by the owner to suit their cosmetic desires and refine performance.

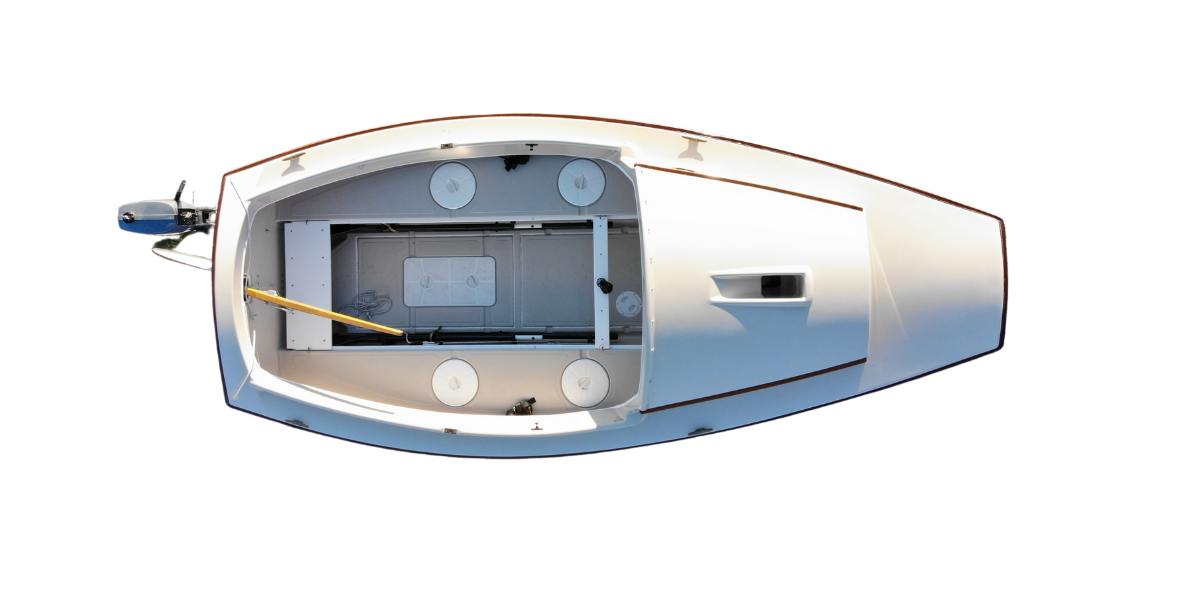

Fiberglass SCAMP Overhead View

Shown with optional floor storage hatch and optional wood trim. Motor not included.

12' Scamp Full Specifications

| LOA: | 11’11” | |

| BEAM: | 64″ | |

| DISPLACEMENT: | 420 lbs | |

| Model-Specific Options: | ||

Sailaway ready from

- 17′ Jersey Skiff

- 17′ Salish Voyager

- 16.5′ Melonseed

- 15′ Lobster Boat

- 14′ Whitehall

- 12′ Point Defiance

- 10′ Navigator

- 9.5′ Captain’s Gig

- 8′ Nisqually

- Available Now!

- New In Stock

SCAMP Photo Gallery (click to enlarge):

More about the scamp:.

- 48 North Review

- SCAMP Options (as of Jan 2016)

Gig Harbor Boat Works, known for their strong, esthetically pleasing rowing boats, has already shipped a number of the new SCAMPS all over the country and overseas. “The kit boat has a lot of intricate details that the home builder may not have the talent or tools to build,” says Dave Robertson, owner of GHB. “With the fiberglass version, they can enjoy using the boat right away.” The GHB boat is truly sail-away complete; from oars to sails.

There are many innovations designed into the SCAMP that make it truly a big little boat. One thing that usually takes up a lot of cockpit room of most small boats is the centerboard. The SCAMP’s centerboard, very heavy but swings up easily for trailer or grounding, is offset to starboard so that it doesn’t intrude into the cockpit. I’ll let you call Dave to explain the physics of the offset. Suffice it to say that we didn’t notice a difference on either tack. The result is it opens up the cockpit which feels more like that of a of a San Juan 24.

The boat was surprisingly quick and very stable. “This boat can’t be just 12’long,” I thought. I stood up and rocked it side to side with minimal affect. It felt like 20-footer. Sailing the SCAMP made me a believer that it actually would be a safe and enjoyable way to explore the San Juans, as well as just knocking around the bay for a fun day of sailing. The SCAMP had lots of surprises, all good. I have to say it’s the biggest little boat I’ve ever sailed.

See the price list for current pricing of Scamp options

Cosmetic options

Hull color change ( white hull exterior is standard).

This option allows you to customize the hull exterior to the color of your choice. For the best balance of pizzazz and reasonable maintenance, we recommend that color only be added to the top strake and the balance of the hull be left white. Why? A white underbody doesn’t show scratches like a dark color, it is easy to repair, and Scamp has high freeboard so a darker sheer strake lowers the apparent freeboard. If you add color to the top strake, we will extend the color across the top of the bow and leave the stern all white for best visual balance.

Deck and interior color change (Bisque Tan deck and interior are standard)

The Bisque color is neutral so goes with any accent color – it also doesn’t show scratches and is easy on the eyes. However, we can make the topsides any color you want; for more than a basic color change the price varies with color and pattern.

Bronze Deadlights (white nylon deadlights standard)

Mahogany gunwale trim (standard gunwale trim is tan vinyl).

This wood trim option also includes mahogany ‘eyebrows’ on the cabin sides. Other wood trim such as coaming or seat top overlay is available on a custom basis.

Custom Sail Color (standard is ‘Egyptian cotton)

Any color available, price varies with color and pattern.

Hull options

Stainless steel keel guards.

Over 90% of the boats we build are specified with stainless steel keel protection. Fiberglass is a wonderful boatbuilding material; easy to conform to compound shapes, hard smooth finish, eminently repairable; but it is NOT abrasion resistant. Pulling a boat onto a beach is asking for grief, especially if parts of the boat have a sharp edges forming high pressure areas…. like the keelsons on Scamp. Protecting the keelsons is a lot cheaper than fiberglass repair.

Floor storage hatch

There is a lot of usable, easily accessible space under the cockpit floor. This optional storage is a sealed chamber approximately 18″ wide x 30″ long with depth varying from about 8″ at the forward end to 4″ aft. The hatch accessing the storage is a rectangular Armstrong style with 14″ x 21″ opening. If you plan to add electric propulsion or accessories this is an ideal location for batteries!

Bilge pump, handheld manual style

Rain and spray is contained in the cockpit sump at the transom. This can be scooped or sponged out easily. However, if you somehow get water inside the seats or underfloor that is a relatively inaccessible area. Although chances of getting much water in this area are slim, it helps to have a portable handheld pump handy.

Outboard motor bracket

Removable outboard motor bracket

Bolts to outside of transom. Owners have noted that a permanent motor mount on Scamp is, well, ugly. So we researched a removable mount that has only a flat plate permanently bolted to the transom. The actual motor carrier clips onto the plate with a simple quick pin, no tools required to install or remove the bracket.

Bronze 5″ cleats

Bronze cleat

Stainless steel pop–up cleats

Pop-up cleat

Performance / operational options

Trailer, galvanized, custom designed for scamp.

Scamp is very difficult to fit correctly on a trailer; the twin keelsons, wide chines and flat bow just don’t work with any standard trailer. We designed a custom trailer specifically for this hull. It is 100% galvanized and has three aft rollers to accommodate self centering on the keelsons. Scamp has a tendency to skate sideways when loading, so we install carpeted side guides and a central crossmember roller to make loading simple. Forward is a carpeted transverse bunk to support the fairbody, and finally a special twin chock winch pedestal. Oh yeah, bearing buddies are standard too.

Swiveling mainsheet cleat with removable base

The mainsheet cleat is fastened to a transverse board between the seat tops. You can adjust the position of the board and cleat fore or aft the length of the cockpit or remove it entirely by pulling two stainless steel fastpins.

Jiffy reefing

Three Reef points in the sail are standard, but there are no reefing lines or cleats. If you want jiffy reefing we”ll set up two complete ready to use reefs.

Compass, bulkhead mounted Richie #RITV57.2

Oars, 9’4″ 2-piece fiberglass shaft with bronze oarlocks.

Scamp’s high freeboard and wide beam requires 9’+ oars which are impossible to stow in Scamps’ cockpit. We have engineered high quality, strong 2 piece 9’4″ spoon blade oars that disassemble and store concealed inside the cockpit coamings. Another practical storage area is on the vertical seat sides, clipped into modified fishing rod holders.

Cover for trailering/storage

Top Notch fabric, custom sewn for Scamp. Protects deck and cockpit during trailering and storage.

Bimini/Camping style cockpit cover

Fully enclosed bimini cockpit enclosure with zippered windows and side curtains. Sides zip off individually for fully-customized protection from the weather.

Scamp spar and sail bag

We are always looking for ways to simplify sailing, and one of the most vexing chores is the assembling the rig. Wouldn’t it be nice to be able to pull the completely assembled, ready to hoist sail and spars out of a bag? This special bag is 12′ long and has two long pockets; the lower pocket is for the two-section mast. The upper pocket has a full length zipper so you can store the sail lashed to the yard and boom with even the jiffy reefing in place. Just pull the mast with halyard attached from the bag and plop into the cabin-top ‘Scamp Ramp.’ Then fasten your halyard to the Yard and hoist the whole rigged sail out of the bag. All you have left to do is run the halyard and downhaul to their respective cleats, clip the mainsheet and lazy jacks to the boom and away you go. 10 minutes, done.

Stirrup reboarding system

Transom boarding ladder ….. still under development, scamp rigging tutorial.

If you’re not familiar with balanced-lug rigging, here’s a great tutorial showing how to set up this simple and intuitive rig.

Imagining your ideal boat?

Take a turn through our online quote creator to see the possibilities. No haggling, no commitment.

Explore More Boats

SmallCraftAdvisor.com

Small-Boat Related Message Board

Skip to content

- Subscriptions

- Back Issues

- Instant Downloads

- Boat Plans & Kits

- Message Board

- Classifieds

- Quick links

- Home Board index SCAMP

- It is currently Sun Sep 22, 2024 6:35 am

- All times are UTC

Scamp plan vs kit build cost

Moderator: Moderator

Post by Jedi Clampette » Sun Apr 20, 2014 5:00 am

Re: Scamp plan vs kit build cost

Post by simeoniii » Tue Apr 22, 2014 1:15 am

Post by JohnT » Tue Apr 22, 2014 12:32 pm

Post by kenjamin » Tue Apr 22, 2014 1:41 pm

Post by fred4win » Thu Apr 24, 2014 2:59 am

Post by Peter E » Thu Apr 24, 2014 5:48 pm

Post by Derek » Fri Apr 25, 2014 12:04 am

Post by Brent65 » Fri Apr 25, 2014 12:10 am

Post by Roux » Fri Jun 20, 2014 6:35 pm

Return to “SCAMP”

- Boat Building and Designs

- Small Boat Events and Gatherings

- Race to Alaska (R2AK)

- West Wight Potter

- Precision Sailboats

- ↳ News and Annoucements

- ↳ General Discussion

- Home Board index

Powered by phpBB ® Forum Software © phpBB Limited

Style by Arty - phpBB 3.3 by MrGaby

Privacy | Terms

- My Boats & Boat Articles

- Boatbuilding Plans

- Scamp Sailboat

Steps in Building a SCAMP sailboat

Links to all my scamp building pages.

Building a Scamp Sailboat, I Continue Laying Out and Cutting

All the bulkheads are checked and cut. I've relaxed a bit.

I laid out the bottom of the Scamp today. It was a quick job. I had glued up a nice pine batten but it broke, so I made another using left over 9mm plywood scarfed in the middle, as fair a curve as can be.

I did not join the extra plywood onto the front to make a long enough piece, I just clamped it very well in position and drew the curve. I will join after cutting out. I'll combine all the joining in one happy day and save a bit of time. I have quite a lot of space in the shop so that will work.

Before cutting the bottom I marked the center really well and also the area that will be cut out for the centerboard. I'll wait until I've made the centerboard case before I cut.

Somehow cutting the bottom feels important.

That's the plywood stamp on my 9mm. It's probably Chinese. So far it's been nice and I've not seen any difference with other Meranti I've used except that the back veneer is not necessarily as pretty. I can live with this for an almost 40% lower price. Good marine grade ply. Our exchange rate right now is quite terrible. Here is a wikipedia article on BS 1088 grade plywood

Laying out the cockpit floor is not too complicated. It is a long piece that will be cut in 2 parts and assembled. This particular sheet is slightly damaged from the transport and I'm having to cut around bad spots. I think it won't be a problem because the layout does not use the full width.

I also cut one of the mast box pieces. I'm getting a nice pile of pieces. I might have to assemble them sometimes soon!

Bottom layer of cockpit is cut, next is the top layer to reinforce the floor. It is cut just slightly smaller to create a drainage ditch.

I cut out the cockpit sole doubler, It is slightly smaller than the sole/top piece to make a drainage channel. I also cut the transom cap, which required a bevel.

It went quickly using the smoothing plane but I got a bit of tear-out and used the sander to smooth the edge. I don't think it's visible in the finished boat.

I spent the day in the shop today cutting out more scamp parts. I got the cabin top and sides as well as the aft pieces of the garboard.

I had a stupid attack and I swear I had to draft every part twice... almost. I'm cutting in the 6mm now, most of the parts from the 9mm are done except for the rudder case and a few doublers.

There is a fabulous dragon logo on the 6mm plywood. The surface is nicer than the 9 mm. Surely that means that my boat will be faster and fiercer with such plywood.

There has been lots of arguments to and fro about Chinese marine ply but so far I have not had any reason to complain and have not found any real flaw. One sheet had ugly top veneer but it was sound. I don't really think that's a flaw though.

I will now be laying out and cutting the side planks.

This was the most difficult layout yet. This is where the plan builders have to figure out the best placement of lots of pieces on a sheet of plywood. It was a tricky exercise, for me at least.

One good thing that saved time, I cut 2 sheets of plywood together. Since I was cutting out pairs of side planks this worked very well.

Next is the top deck. It needs to be cut in several pieces and joined.

The funny thing about this kind of boatbuilding is that it takes forever to cut out the parts and day after day all I have to show for a lot of work is an increasing large pile of oddly shaped bits of wood. I think assembly will go quite fast and finishing will take a longer time. Time Will Tell.

This is what a SCAMP looks like. Some Assembly Required. Another benchmark has been reached. I've cut all the plywood pieces. (Except a couple of doublers and reinforcements and the rudder.)

To tell the truth I also have to cut the hole for the mast partner in the top of the cabin. As I build I will have to adjust a little bit I think. I've cut as accurately as I could though.

So far I've had to cut in my extra sheets. If I had taken the time to place the parts more accurately then I could have fit them in but the amount of extra work would be several hours. I also chose not to cut a bulkhead in 2 and re join it later. It's cheaper to have an extra sheet of ply, than to lay out very closely, even at my rate.

This means that I have slightly larger waste pieces and extra plywood to make the centerboard and the rudder blades, so I don't think there is much waste in the end. I will also have wood for access doors and portholes.

In the end I've used a combination of the little Dremel Saw to rough cut quickly and my trusty jig saw for accurate cuts. I'm just more skilled with the jig saw but I think the Dremel would work except for tight curves.

I've cleared the shop and taken down my extra table for now and will start cutting the support straps and mast staves next.

So far I would estimate I have spent about 30 hours laying out and cutting. I had to break this time in many segments because I found the exacting laying out and cutting to be tiring and I would start making mistakes if I tried to push it. This includes laying out but also checking everything at least once and more if I found a mistake.

emails: Christine

This web site reflects my personal ideas and doesn't represent anyone else's point of view.

If you decide to build a boat be careful. These tools can be dangerous. If you don't know how to safely handle something find out. There are lots of forums out there.

IMAGES

VIDEO

COMMENTS

Installing the bow eye. Making the portholes/deadlights. Oar Socket Placement. Making the SCAMP mast. Turning SCAMP over. Sanding, marking waterline and Painting outside of hull. Finishing shaping the Bottom. Making the centreboard. Centreboard pivot and details.

A detailed account of building a SCAMP sailboat, a small wooden boat designed by John Welsford, from plans and materials. See photos, videos, specifications, tools, materials, and links to the build log by hour.

SCAMP features an offset centerboard, massive flotation from sealed seats and stowage cabin, a water ballast tank holding 173 pounds of water, an after cabin "veranda" that functions like a hard dodger, and a flat bottom and skegs for beaching. PLANS: Complete plans now available on 7 24 x 36" sheets. A complete "Building guide" with suggested ...

The home port for all things SCAMP sailboat, including plans and kits. The home port for all things SCAMP sailboat, including plans and kits. top of page. HOME. Members. OWN A SCAMP. GALLERY. LINKS. SHOP. ... SCAMP Building Plans PDF DOWNLOAD. Price $149.00. Add to Cart. SCAMP Building Plans. Price $149.00. Add to Cart. SCAMP Articles Package ...

Building the Frame. While I have spent quite a lot of time making the mast, centreboard and rudder, and cutting out all the main parts of the boat, it does not look like much. This is about to change as I start to go 3-D. The SCAMP is built right side up at first, on a curved platform. This platform not only gives the proper curvature to the ...

After cutting and fitting 2 small sticks I glued them on the ends of the seat verticals. These will help align the transom and provide bigger glue surface. It will also give me something to clamp against as I fit the various parts together. There will be many such sticks on the scamp.

Welcome aboard! SCAMP Building Plans. $149.00Price. Quantity. Add to Cart. bottom of page. Complete SCAMP building plans. Eight detailed 24 x 36" printed plans sheets plus the detailed spiral-bound SCAMP Builders Manual. Welcome aboard!

In 2015 I built a scamp sailboat from a kit. I took 3 years to build it, taking my time. I did this YouTube video to encourage people to finish their Boat an...

Decided to build a boat. How hard could it be? Let's find out! It's a SCAMP (designed by John Welsford). I've had my eyes on the design for a while, and ...

Learn how to build a SCAMP sailboat with master instructor Howard Rice via live sessions and podcasts. Save money and time with the virtual SCAMP Camp model and access the full SCAMP Camp archived podcasts and finishing modules.

Building SCAMP, an 11 foot long, wood sailboat. Ever since I was a kid, I've been amazed with boats, much in the way my grandson flips out over trains. Learned to sail in the early 70's, at Rhode Island's Camp Yawgoog. I've been a boat nut ever since. Now I'm a restless boat nut, having sold my last boat almost 4 years ago.

In this video I show the assembled SCAMP building jig and discuss how to prep the hull planks for joining with precut puzzle joints.Wooden Boat Dan from Hook...

The rest is history: More building plans and kits for SCAMP have been sold over the years than any other small cruising boat we can think of. Besides the original wooden version, Gig Harbor Boat Works was licensed in 2013 to produce a fiberglass SCAMP, and the little giant killer—in wood and fiberglass—has since its debut been at the center of various small-boat rallies, workshops and ...

SCAMP gets side planks. The Scamp has 3 sets of planks. Each is made from 6mm ply joined. The 2 bottom planks have bevels to accommodate the plank above it. Joining Planks. I used Dynamite Payson's method of joining the planks. He suggested butting the 2 sides, sanding to remove some thickness and using fiberglass to glue the 2 sides of the ...

From the archives: The SCAMP rendezvous meeting at the shop. The 6-page review covers the SCAMP as a whole, including both kit-constructed models as well as the fiberglass version made by us here at Gig Harbor Boat Works. It is filled with the personal feedback of both DIY builders and those who've purchased our fiberglass boats ready to sail ...

I completed my SCAMP Sailboat project in 319 hours. Note that this time includes customizing the trailer, making wooden oars, making wooden cleats, updating the MKI bulkhead to the MKII design, building a custom wooden boarding ladder, making the portlights, and painting a 6 color scheme. If one went for a one or two color paint scheme, and ...

SCAMP Rigging Kits. $69.99 - $329.99. Boom and RUNNING RIGGING plus Hardware 2 10-foot lengths of 3/16" Raid Braid for 1st Reef2 20-foot lengths of 3/16" Raid Braidfor 3rd Reef4 SD-043030 3" cleats for reefing lines1 60-foot length of 3/16" Raid Braid for Topping / Lazy jack system (cut to...

The Scamp is a seaworthy 12′ sailboat that can handle a good dose of adventure. Just under 12 feet in length, Scamp boasts an unusual combination of features that give her the unique ability to explore waters too shallow for a larger boat, while retaining most of the bigger boat's comforts and capabilities. An offset centerboard opens up ...

When I posted the photo of the mast location opening, Simeon Baldwin suggested that the sides could be raised by about 3/4 of an inch to allow a sleeve to be installed around the mast and fastened to this extension. This would reduce the amount of rainwater coming in through the mast opening.

Building Birdsmouth Mast for SCAMP Sailboat. SCAMP ARGO's Birdsmouth Mast is made from Sitka Spruce. Construction photos below. The plans call for a hollow wooden mast made using "birdsmouth" joints. It makes for a strong, light, and quite pretty mast. The hollow design minimizes weight aloft and makes stepping the mast easier due to the ...

Steps in Building a SCAMP sailboat. Links to all my scamp building pages. I started the Scamp rudder. I looked in the leftover plywood pile and cut out some blanks to glue up the Scamp Rudder blade. I put a couple of pieces through the thickness planer to slightly reduce the thickness so now I have a quite accurate pile of wood. A little epoxy ...

If you build a SCAMP, you'll be joining a rapidly growing community of SCAMPers that I think have developed a special affection for all 11' 11" of this great little boat. Aside from the problem with the nesting plan, the support from Small Craft Advisor, the folks on the SCAMP forum and from the designer, John Welsford, has been truly outstanding.

Building a Scamp Sailboat, I Continue Laying Out and Cutting. All the bulkheads are checked and cut. I've relaxed a bit. I laid out the bottom of the Scamp today. It was a quick job. I had glued up a nice pine batten but it broke, so I made another using left over 9mm plywood scarfed in the middle, as fair a curve as can be.