Sail Wildling

Why should we care about a rotating mast.

Outremer offers 3 mast options on the 5X. Fixed aluminum, fixed carbon fiber and rotating carbon fiber. Having no experience with rotating masts, my initial reaction was that it seemed unwise to add the complexity of a rotating mast to a boat being used for long distance cruising. As with all boat decisions there are pros and cons, and so I needed to find out if the benefits of the 5X rotating rig are worth the extra cost and complexity.

Outremer 5X under sail with the carbon fiber mast rotated. Note the radar dome installed on the spreader.

The first two fixed mast options are pretty easy to understand, as it’s a simple question of weight. The carbon fiber mast weighs 280 kg (616 lbs) less than the aluminum mast. Taking weight out of the boat is important, and it’s especially important to save weight up high, as this has the biggest impact on the pitching motion of the boat. Less weight aloft = less pitching = more comfort and more speed.

So, we know we want a carbon fiber mast, so the next question is fixed or rotating? To figure that out, we need to look at why Outremer has gone to all the trouble of designing a rotating mast for a cruising boat in the first place!

It turns out the benefits of a rotating mast are not just theoretical, and I discovered that for myself when I did the test sail on the 5X Addiction . We were going upwind in a light breeze of about 7 knots just after completing a tack, with the rotating mast set straight on the center line of the boat. Once we had settled onto the new tack, we rotated the mast into the wind and I could literally feel the boat surge forward! Tests at different wind speeds and angles confirm that there is a 10-15% increase in performance with the mast rotated. This is great, but how does it work?

When a boat is traveling with the wind coming from in front of the beam (<90 degrees) the sails operate as airfoils in much the same way as an airplane wing.

Rigid wing airfoil

When the wind strikes the front edge of this rigid wing, the air is separated and must travel a longer distance in the case of particle A vs particle B. This creates a higher velocity on the top surface and a corresponding area of low pressure. So the wing is pulled upwards due to the lift force developed. This force is called aerodynamic lift.

Flexible sail airfoil

In the case of a sail, there is no rigid bottom surface, so it is less efficient than a rigid wing, but it still forms an airfoil because the two air particles A and B must travel different distances, and so a low pressure region of lift is created in the same fashion as a rigid wing. Around 2/3 of the driving force of the sail comes from aerodynamic lift, with the remaining 1/3 generated by the force of the wind striking the inside (bottom) surface of the sail.

This is the case for an ideal airfoil, but on a sailboat there is a mast in front of the leading edge of the sail. The bigger the boat, the larger the mast cross section has to be to handle the force of the sails, and this becomes a factor influencing the shape of the airfoil we are able to present to the wind.

Fixed mast airfoil

This diagram shows the effect that a fixed mast has on the airfoil. Since the wind must make a tight turn around the mast, a turbulence zone is created which reduces the amount of lift being generated by the forward section of the sail. It also drives the lift force direction slightly aft, reducing the ability of the boat to sail upwind.

Rotating mast airfoil

By rotating the mast into the wind, we can clean up the leading edge of the airfoil and eliminate the turbulence. This increases the lift force and moves the lift angle forward, giving us more speed and better pointing ability (how close we can sail, or point, into the wind direction).

There are other benefits to a rotating mast, regarding reefing the mainsail. Normally when reefing, you turn the boat into the wind to take pressure off the front edge of the sail in order to lower it. This puts the headsail into a luffing mode which is uncomfortable and potentially damaging to the sail. With a rotating mast, you can turn the mast into the wind and lower the mainsail. This allows the headsail to keep drawing during the reefing process and is easier and places less stress on the rig and the crew.

Because the rotating mast is in fact a rigid airfoil, it acts as an additional 12m2 sail, so by rotating the mast to the centerline position as the wind increases, you have the ability to depower the sail, which in effect, becomes an additional reef point.

And for the mathematically inclined:

12m2 mast / (12m2 mast + 125m2 mainsail) + 6% lift improvement = 15% performance increase from a rotating mast vs a fixed mast of the same size. And conversely, straightening the mast when the wind increases will de-power the mainsail by 15%.

So what’s the catch?

As always, all this goodness comes with a price, and in this case there are three issues that have to be considered:

- The additional mechanical complexity needed to operate the mast rotation system

- Compensating for the error in the wind angle reading when the mast is off centerline

- Dealing with the error in the radar signal when the mast is rotated

For us to be able make the decision to choose the rotating mast option, we needed to find a solution to each of these. Here’s what we came up with:

Mechanical compexity

This one was actually pretty easy. Outremer has done a nice job of designing a simple and robust system for securing the mast, and operating the rotation controls from the cockpit. It does add a little more complexity when sailing, but to me it’s negligible, and since I am a committed sail tweaker anyway, I am looking forward to having another power control on the boat. Our conclusion: Outremer’s system is fine for our needs and has been proven over time on a large number of their other boats. We are happy to install it as designed.

5X Rotating mast

Rotation control lines led back to cockpit

Wind angle error

When the mast is rotated, the wind angle measured by the sensor at the top of the mast will be incorrect. This is because the wind angle instrument measures angle with respect to the mast center-line. So if the mast is rotated 20 degrees, the wind angle will read 20 degrees less than than actual apparent wind. This is a problem, but it can be corrected in software by the instrument system as long as we can provide an accurate reading of the actual angle of the mast.

To read the angle of the mast, we need another sensor:

NKE mast rotation sensor

This rotation sensor from NKE has been used by many offshore racing boats and has proven very reliable. The only concern I had was the cable that connects the mast sheave to the sensor body. If it breaks, there is no way to fix it without taking the mast off. NKE claims a 10 year life for the cable, and Outremer has never had a failure, but they add a second spare cable at the mast base that can be fitted if there is a failure of the original cable. Our conclusion: The benefits outweigh our concerns over the reliability of the sensor. If the sensor did fail, it will only affect the wind angle reading, which is a non critical data point, so we’re OK with this.

Radar image error

Most sailboats install the radar dome on a spreader located at the top section of the mast (see the first photo in this post). A high elevation for the dome provides greater radar range and minimum interference. On a rotating mast, the radar will provide significant errors when the mast is rotated. For example, if you have the mast rotated and a ship is approaching in the dark and headed straight for you, it will appear as through the ship is actually approaching from the side. This is not good.

As I write this, in September 2014, there is no reliable solution to this problem. The radar image angle should be able to be corrected in software in the same way as the wind direction, but in practice, other owners have experienced system failures where the correction angle is lost, so the radar reverts back to a non-corrected image. Although this can be resolved by rebooting the radar software, there is no way to tell if and when the system has stopped processing the angle correction input. I expect this will be resolved in a future version of the software, but it still leaves us vulnerable if there is a fault in the mast angle correction sensor.

We feel that a reliable and accurate radar, is an essential safety element when voyaging offshore, so installing the radar dome on a rotating mast is not acceptable to us. Our solution is to install the radar dome on a carbon fiber pole at the back of the boat, keeping it fixed with the vessel centerline. We will lose some range due to the lower mounting location, but it won’t be enough to compromise our safety at sea.

So all in all, the rotating mast option is a good one. It does add some complexity, but we found ways to deal with that and we are happy to be able to take advantage of the significant benefits that a rotating rig provides.

Share this:

12 thoughts on “ why should we care about a rotating mast ”.

I love reading all these details and getting to know Wildling and what will make her tick.

hi – great blog. On radar and rotating masts – two choices: – most B&G systems with a mast angle sensor (same as rudder angle sensor!) will calibrate the wind and radar systems to compensate for rotation; – mount a broadband radar unit on the bowsprit or a carbon pole on the stern quarter. cheers Malcolm

Hi Malcolm, thanks for the input. We are going with B&G instruments, so no problem with the mast angle and wind, but according to the after sales support folks at Outremer, there have been some issues with the B&G radar losing the offset angle input. A reboot fixes it, but we’re going to install the radar on a carbon pole on the stern quarter to be safe.

Is the radar issue still unresolved in 2017?

I think it’s resolved now, the newer rotating mast boats have the radar on the spreaders. Best check with B&G to be sure though.

received this from B&G: “I have verified with our Product experts in England what the issue is and that the solution is in place with the latest software update for the Zeus 2 and Zeus 3 products. This update was released earlier this year so you will not this issue when you get your Outremer boat outfitted with B&G electronics.”

Thanks Kenny, after thinking about this a bit more, I would still want to verify this with owners that are using the B&G radar with a rotating mast just to be sure. B&G said the same thing when I ordered my systems for Wildling, but other 5X owners told me they were using the latest B&G software and it still didn’t work, so I went with the aft radar mast to avoid any issues.

Given the added complexity and expense, are you still happy with the rotating mast or would a fixed carbon be adequate?

It’s more expensive to buy and a bit more difficult to rig, but there is a real performance boost in light wind, reefing is easier in heavy wind, and there is essentially no hassle or effort required when sailing. I would still choose rotating on the 5X if I did it over.

Hi Doug, love your blog, mate! How do the stays / rigging work with a rotating mast?

Hey, thanks for the comment! The surprising thing about the mast and stays (at least for me) is that there isn’t anything to really think about or deal with. The stays allow the mast to rotate easily, and the mast just orients itself into the breeze. Mostly I just leave it to position itself, so there’s no adjusting or anything to do. When it’s light wind, or I’m reefing, I will position the mast with the winches and lock it in place. Super easy to do! I think the only downside with the mast is that the angle sensor uses a captive band at the mast base. If the band breaks, the mast has to be lifted off to replace it.

I am not an engineer, but I am picturing – which I hope I can diagram in words a ‘fix’ for the Radar dome. Would it be possible to have it on the front of the mast, on a post that swivels – then attach a piece of dyneema – or something very stiff and sun resistant – to each shroud fixing the dome in position and allowing it to ‘swivel’ and stay forward facing as the mast rotates?

Leave a Reply Cancel reply

Discover more from sail wildling.

Subscribe now to keep reading and get access to the full archive.

Type your email…

Continue reading

July / August Issue No. 299 Preview Now

Rotating Wing Masts—Part II

By reuel parker.

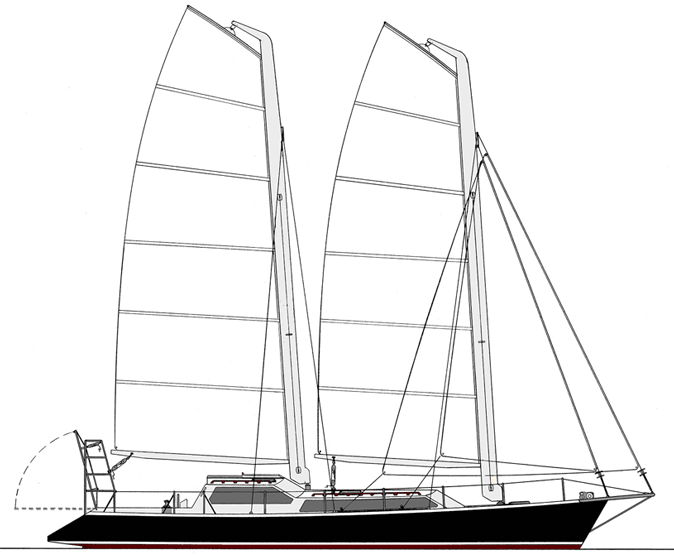

Sail Plan for the Australia 47, featuring L-Head rotating wing masts.

In 2003 I received a commission to design a 47′ aluminum schooner for a doctor in Australia, who wanted a fast, shoal-draft racer/cruiser. I designed new rotating wing L-Head masts for her, using modern hardware, winches and aircraft-grade plywood for the mast sides. The new masts, while based on my earlier low-tech L-Head masts for the Conch 32, were designed considering the conditions likely to be encountered in the Southern Ocean. I designed the schooner to ABS requirements for offshore racing yachts—all aluminum scantlings being carefully chosen for weight, dimensions and strength. We did a full hydrostatics workup to ensure self-righting abilities in capsize conditions. My engineer Tom Lokocz Adams collaborated with me on this project. I featured her in my article for Professional Boatbuilder Magazine on shoal-draft stability (issue #139), and included her in my IBEX session on the same subject in the fall of 2013.

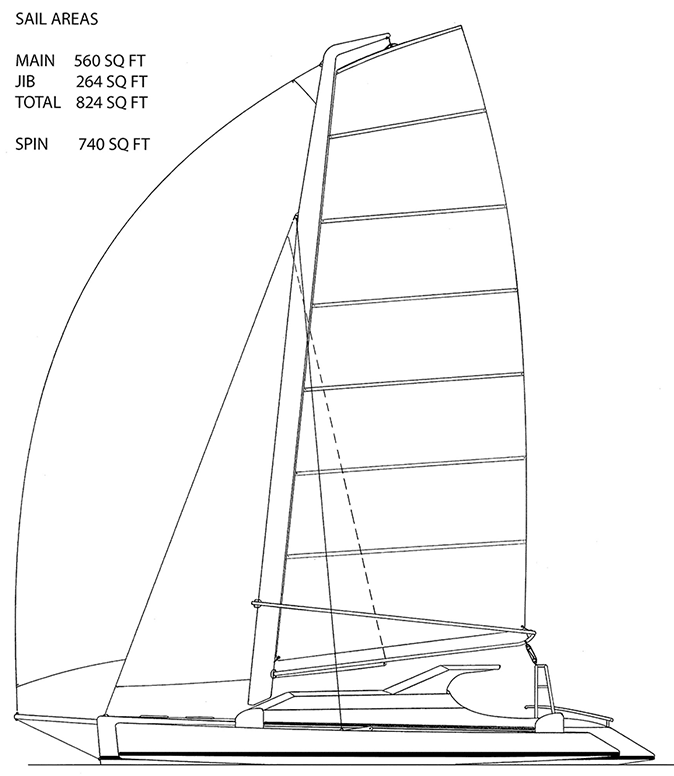

Sail Plan for the Trimaran 40.

I also designed my first multihull, the Trimaran 40, in 2003, and gave her a similar rotating L-Head mast. The prototype for this design is being built in North Carolina. I put weeks of work, and years of thought, into my trimaran design. I was especially impressed with the generous open space manifested in the interior and the cockpit. I have concluded that trimarans can be an excellent choice for cruising, and I wonder why I don’t see more of them. The design is complex and simple at the same time, and I drew many pages of detail drawings, creating one of the most thoroughly documented sets of plans in my portfolio (most of my designs being frankly simple and less thorough).

I had also been working on a “Basket Boom” concept (an aluminum wishbone with a bottom strut), which would be self-vanging, and would contain the sail and battens when lowered. A sail cover fits into the Basket Boom with a zippered flap to cover the sail when lowered. I later retrofitted the Basket Boom for my Australia 47 design—but first featured it on the Trimaran 40.

The L-Head mast, the fully-battened sail, and the laminated yard/gaff/head derive directly from the Chinese lug rig. Having been interested in Chinese Junks for many years, I researched the type as extensively as I could and then began designing Junk rigs, starting with two commissioned custom designs (the Scow 45 Junk in 1991 and Snowy Egret 39.5 Junk in 1994). A remarkable feature of the Junk rig is the ability, through a vast complexity of rigging, to completely control sail shape, including depth and location of draft, and vertical twist. The Chinese lug rig has both positive and negative aspects that are too involved to delve into here (perhaps in another blog?)—but what I was trying to achieve was an articulated wing of very modern design and construction that would epitomize the qualities of the Junk sail .

The primary purpose of the inverted L-Head is to support the large upper panels of an articulated bat-wing sail. The secondary purpose is to automatically align the mast to the sail, creating a continuous optimal foil shape. By adding a mast tiller at the base of my L-Head wing, the sail becomes completely articulated: twist and angle-of-attack can be totally controlled by using the sheet, L-Head, Basket Boom and mast tiller in concert with each other.

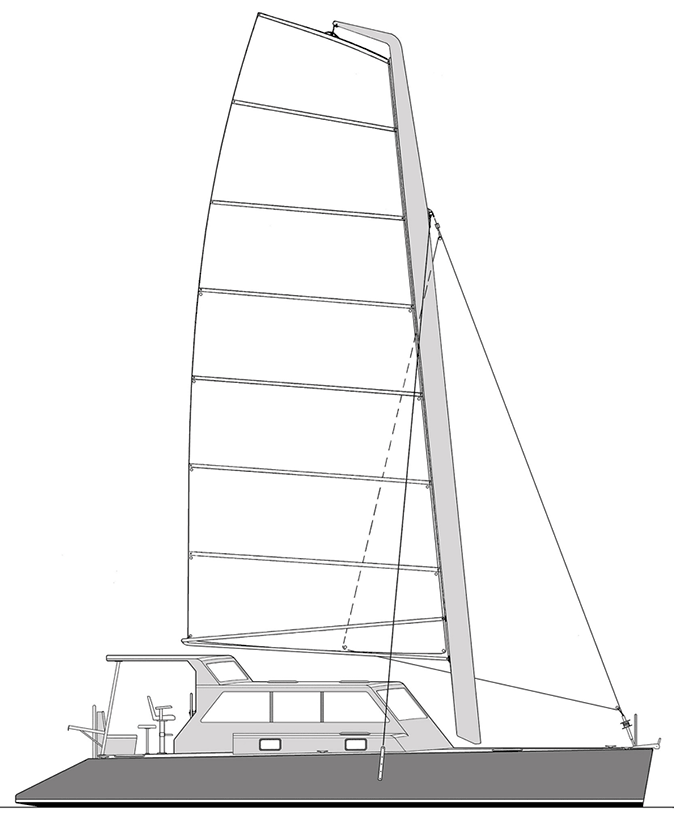

In 2012, after thirty years of study, observation and numerous failed attempts (on paper), I designed my first cruising catamaran, the Sharpie Cat 42. I also adapted my L-Head mast for the cat.

Sail Plan for the Sharpie Cat 42.

The mast designs for these three boats are very close, with dimensions altered to suit the individual requirements of each. I provided jumper struts and stays for the Australia design, and included them as an option for the multihulls also, as the wide stability platforms impose high loads on the mast despite the correspondingly wide shroud angles.

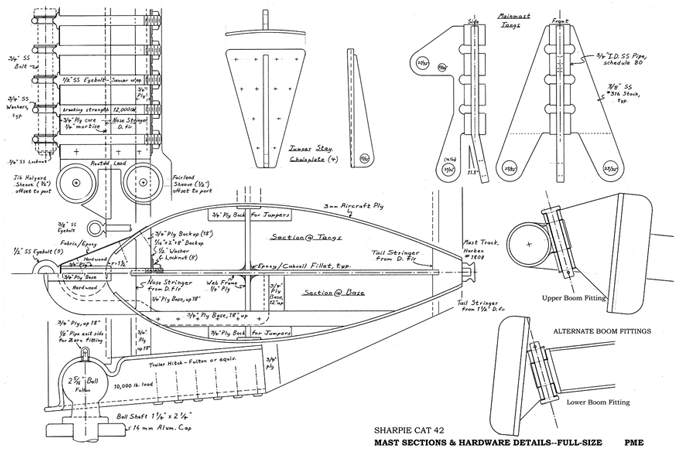

While I specified five-ply aircraft-grade 3mm plywood for the mast skins, it is possible that Lloyds-certified three-ply 3mm marine plywood will suffice. Quite frankly, an L-Head mast must be built and tested to know how strong is strong enough. In the world of racing, it is often said that “if you can’t break it, it’s made too heavy!” A certainty is that these masts will be very light. Again, as for my Conch designs, I eliminated the infamous “Jesus shackle” and replaced it with a system of five eyebolts supporting a rotating mast tang for attaching shrouds and forestay. I also incorporated internal halyards using Schaefer Delrin sheaves.

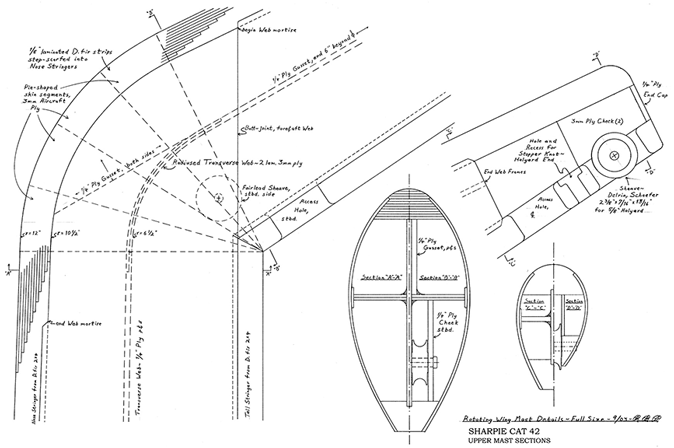

Mast design sections for the Sharpie Cat 42, page one.

I opted for Harken mast track and “bat-car” slides that plug into fiberglass full-length battens. Key West entrepreneur Sonny Eynman used this system on his charter version of my Exuma 52 design SUNNY DAYS (later sold to Danger Charters and re-named DANGER’S PRIZE). During sail trials for the new boat, he called us on his cell phone complaining that the boat was going 10.5 knots in 15 knots of wind—he feared this kind of speed would terrify his charter guests. When I inspected the new boat, I was very impressed with the Harken system, and realized it would make an excellent choice for a rotating wing.

Mast design sections for the Sharpie Cat 42, page two.

As I think about a sailing retirement home for myself, I am torn between my love of the gaff-rig schooner, with laced on sails—and a fast multihull with my L-Head mast. I am also tempted to build my Australia 47 design in cold-molded plywood instead of aluminum. I simply may have to build one of these three because no-one else is doing it, and I want to experience it first-hand!

2/3/2014 St. Lucie Village, Florida

ACCESS TO EXPERIENCE

Subscribe today.

Publishing dynamic editorial content on boat design construction, and repair for more than 40 years.

1 YEAR SUBSCRIPTION (6 ISSUES)

Print $39.95, digital $28.00, print+digital $42.95, from online exclusives.

The Gift of SEA FEVER

Whiskey plank.

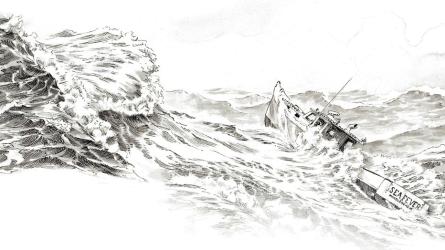

The Delivery from Hell—Part One: New Jersey

Aboard TRIXTER

Extended content.

From the Community

1929 Hacker Craft Runabout 18'

Jimmy Steele Peapod

Good Vintage Boat - Hull Number 66 - Completed In 1989.

1967 Crosby Striper #86

Short cabin version. Restored in 2020 new lower frames, knees, floors and cockpit.

Boats Plans and Kits

Switzer Bullet 136

Information on the home-buildable Waters-Wing carbon-fiber mast

A very detailed (90+ page) illustrated manual is now available for building a very efficient and good looking CF wing mast of 8m, 9m, and 10m lengths, that sells for US$179 via Paypal , with rights to build ONE mast. (Last updated Jan 2021). Design data to extend mast design validity to 11m is now also available. (This design is now referred to as the Waters Wingmast Mk.l, to differentiate from a more elliptical Mk.ll design that, while using the same basic construction principle, is now being developed for wingmasts in the 11-15m range). This Manual will be available after the prototype Mk ll has been well tested .. date previewed late 2023. Mk.ll manual cost targeted to be US$249.

May 2022 Update. The first Mk ll (12.2m- 40ft) CF WingMast is now complete and ready for a full season of racing this summer on a F28R, and the builder says 'all looks great'. (For more complete detail and tests of the Mk.ll - see below)

The Mark l manual contains over 100 photos and sketches and shows all details, as well as defining all the procedures and cloth layup required for each mast size. See reviews added below.

This enables one to build a CF wing mast at 10-12% of the cost of a pro-built mast, so the savings are very significant. The trade-off is that, without vacuum-bagging** and/or resin infusion, the weight is a little greater, but still measurably less than an alum mast of the same section, as well as being stiffer and less expensive. The 8m mast, c/w all fittings and the diamond stays, weighs around 45 lbs - but keep in mind that this design covers a wing section of close to 3:1 (depth to width) and not the more typical section of about 1.5:1 that of course uses much less material but is far less efficient aerodynamically. The advantage of the deeper rotating wing (approaching 3:1) is in its performance efficiency upwind, and this more than offsets the slightly extra weight.

**NOTE: For those who have the equipment and extra manpower to get the resin and bags on quickly, there are now suggested ways to add vacuum-bagging to this build method. Details available for anyone who purchases the manual

To date (May 2022), six masts to this design have been built, and one has been extensively tested over 6 seasons. Many others are now under construction. See below for Comments.

The completed mast has proven strong and durable and has a structural advantage over most other masts by having a built-in transverse web for its full height, rather like the 'spar' within a plane's wing. This not only adds considerably to buckling resistance but also creates 2 compartments; one for the internal halyards, and a larger one that may remain sealed as an air chamber, depending on how halyards are arranged. Also note that this mast has an attractive built-in taper above the hounds, in both width and depth. If built and finished well, this mast can look totally professional.

The purchase process is defined below:

----------------------------------------------------------------------------------------------------------

Added April 2022: Introducing the Mk.ll Waters Wingmast ... and how to purchase.

The first thing is to sign the Waiver that is at the bottom of this page, and return it to: [email protected]

Then, the fee for the appropriate WingMast Manual is sent by PayPal to the same email address. and you will then be sent the PDF files. Data for the 11m mast is now included in the Mk1 manual so one can interpolate the dimensions, thicknesses and cloth lay-up to suit the final mast length. If your trimaran has a beam much in excess of 55% of the mast height, please contact the mast designer as you may need to use a larger section to handle this unusually high righting moment, depending on your ama buoyancy.

For masts of 11m and over, the new Mk ll mast** is recommended but this manual will not be available until late 2023 (check latest update below), giving time for writing up the Manual in detail after testing of the prototype that has just been completed.

Please note that this wingmast is for a multihull that does not 'sail on its ear', so such wingmasts are not recommended for mono's, unless stabilized with foils.

** For those wondering: why the Mkll, and what are the differences with the Mk l ?

Basically, the Mk.ll uses the same construction method, but as the nose of the Mk l is a radius closely based on the mast width, this starts to get too blunt and large for the larger mast sections over say 90mm wide. So for the Mkll, the nose is made more elliptical. Also, the rotation force of the larger masts can get quite high, so the pivot (and central web) has been moved back relative to the chord dimension. In addition, the supporting cables are attached to a rotating (not fixed) beak, the base pivot support is stronger, and the masthead cap can be arranged to take up to 4 internal halyards.

Finally, most larger masts over 12m will use a track for batten-slides or cars, so that's also been factored in. While the elliptical nose gives a finer, less resistant air entry, the more rounded nose of the Mk1 will be less critical to stalling when the approach angle to the apparent wind is less well matched.

Also, because of the larger size and material cost, a few jigs are suggested to further control construction tolerances for the larger Mkll, added steps that are just not considered necessary for the Mk.l masts under 11m. The Manual for the Mk.ll wingmast will also explain how and where, vacuum bagging and/or resin infusion can be used to advantage.

NEW: For those wanting more information on the differences between the Mk.l Wingmast & the Mk.ll ... GO HERE

Mk.ll Test Results

In June 2022, the first Mark ll Waters Wingmast was really put to the test. It was stepped on a racing Farrier F82S and though untried and untested, entered into one of the most gruelling races in Europe ... a 900 mile race up the entire length of the Baltic, starting in Wismar, close to Denmark and ending in Torn, only 100 miles from the Arctic Circle. To sail this distance and back home again, involves over 2000 nmls of sailing over about 2 weeks, with winds from all directions.

Well, the mast performed flawlessly and helped this relatively small boat beat other multis that were up to 50% longer, and break a 7 year old record by 17 hours for the fastest time ever by a multihull for this race. If you want more of the story, .. HERE it is. The boat (and wingmast) competed in the same race in 2023 but in lighter conditions, yet once again she finished 1st Multihull.

While the Mk.ll Manual (11-15m) will now not be ready before Spring 2024 due to other priorities taking longer than expected, if someone is really eager to get started, an arrangement can be made to start making the mast bench and the central web, based on the Mk.l Manual, as these parts are of the same design - just larger. We can give you the exact size for your particular mast. The Mk.1 manual is presently still US$179, but if you purchase the Mk.ll Manual later on (keep proof), you will be given a $120 rebate on the cost of the Mk.ll or Mk.lll Manual, that may vary with your specific mast size and needs.

This approach is offered for the benefit of the builder, but to build more than one mast, a full manual must be purchased for each mast to cover the Design Royalty. (The design and testing of these masts runs well into 5 figures, so just a small part of this cost is shared by each builder via the Manual purchase).

Because enquiries are already coming in for masts in excess of 15m, a slightly modified Mk.lll will also be offered later, that will use the same basic design as for the Mk.ll, but have double diamonds to safely deal with the greater height.

Mike Waters, n.a. for Small Trimaran Design

.

Waters wood wingmast: .

The build method is described through 3 sheets of detailed plans and a 15+6 page Manual full of illustrations. Material cost (using high quality) was about US$200 (in 2019) and the plans sell for US$95 via PayPal . This design has now been used for numerous wingmasts of this format and works fine for its intended use. The CF design is however inevitably more efficient as the material enables it to be stiffer and slightly slimmer. Again, please accept, sign and return a copy of the Mast Waiver below before ordering or I will not be able to send out the plans.

Comment by the designer (2020)

One point that I will add that I’ve not seen mentioned elsewhere, is this.

Because a rotating wing mast assures a better entry to the flow around the soft sail that sets behind it, the smaller the sail hoisted, the more proportionally efficient the rig becomes. I became very aware of this when setting a small but high aspect storm mainsail behind my own wingmast a few years back, and was very impressed how efficiently this small rig performed. Most boats, certainly all cruising dinghies, just struggle in high wind and waves to get anywhere upwind. For them, the W17 is a total revelation. Despite the increased waves due to higher winds, I have been able to make 9 kts (!) to windward and even hit 14.4kt with my W17 on one wild reach … and this storm mainsail is only about 4m2 ! Check here and watch the Storm Mainsail performance Video

As a performance-loving octogenarian, I can tell you it’s a really fun way to sail. Fast but Safer, so I enthusiastically recommend such a stormsail with a wing mast to all builders, for all high wind use.

Comments by builders:

"My CF-wingmast is finally done, and bringing it out of the basement yesterday was like a birth to me! It is truly a spectacular piece of complex design and fabrication inventiveness. I am both proud of the final product and impressed with the build method, all the way through. The build-manual was key to my success. It is extremely complete in design and structural detail and also very helpful with build techniques. In summary, building the carbon fiber wing mast was a three month project which I will never forget. I have a mast that rivals or equals professionally built ones and is probably even stronger. I also learned a raft of new skills, saved quite a chunk of money, but beyond all of that I have the tremendous reward and pride that comes from this special DIY project. It is actually quite amazing to work through this unique design with a process that enables one to start with a bunch of soft carbon fiber cloth and a couple of gallons of epoxy, and end up successfully constructing a state of the art rotating carbon fiber wing mast. Thank you Mike! " Jim van N, USA, 2020 See photo of JIM'S MAST .... first time builder too ! ---- >>

"I am having so much fun making this mast! Just to see each piece come together from a piece of cloth and resin to form a rigid, strong yet lightweight structure, is quite amazing. The design is clever and intriguing and your detailed manual takes most of the stress out of this build so giving me, the builder, every confidence that I will end up with a good result. Thanks a million!" Joe-V: USA, 2019

"I have read through the CF mast manual and am very impressed with your techniques and also how comprehensive the manual is. The depth at which you cover the subject makes this a real bargain for anyone who has thought about building their own wing mast in carbon. It's really a gem of a publication". Alan-J, WA-USA, 2019.

"Hi Mike; thanks for the CF-mast building instructions. It's a great piece of work and I thank you very much that you share your techniques and knowledge in this way". Günter-K, Germany, 2017

"I really enjoyed building my carbon fiber wing mast and would even enjoy doing it all over again! I am very happy with my results and the skills I developed during the building and now have the confidence to use carbon fiber far more than I used to. Even the cosmetics of my mast came out acceptably well as I've received many compliments from friends ... "You BUILT that !!". My mainsail also fits the sail groove perfectly so I am really looking forward to getting it out on the water". Ron-E, USA, 2015

"I received the manual and it looks great! It is indeed an ingenious construction method and the incorporation of a central web further adds to my confidence in the end result. The amount of detail is stunning and everything makes a lot of sense (I skimmed it twice and then gave it a more thorough read-through). I find it well-written and the detail gives a potential builder a lot of confidence that this can indeed be done. There is nothing about this method [from my perspective], that is any more difficult than typical boat building, and most of it even seems a lot simpler than that. So, great work, and I see many more masts being built using this method. I also completely understand your need for a waiver and would do the same in your position, as after all, you have no control over the end product materials, construction or use." Todd-B: USA, 2015 (builder/sailor, experienced with composite construction)

======================================================================================

By requesting these wing-mast plans, I confirm having read and agreed to these Terms and Conditions:

Licence : As purchaser of these Mast Plans and/or Manual, and on behalf of a potential builder / operator, I acknowledge that I am granted a licence for the building of ONE mast only. I agree to request an expanded licence if planning to build more than one. As noted under general Terms & Conditions, information in this Manual is considered IP (Intellectual Property), so no refund can be granted after this Manual has been delivered.

Copyright : I further acknowledge that these plans, drawings, and building manual are copyright material and that any distribution of their content or part of, requires prior written permission from the designer (or his assigns). Any disregard of this will be deemed a violation of copyright.

Acknowledgement of Indemnity : I acknowledge that while the designer may be fully qualified to design this mast with adequate strength for its intended pleasure use, he has no control over the final selection of materials, quality of workmanship, or weather conditions to which the mast may be subjected. As potential builder / owner, I therefore agree to accept the following:

Waiver : That, neither the builder, owner or any skipper, nor their heirs or assigns, will take legal action against the designer, his heirs or associates, for any damage of property, loss of use, injury or even death arising out of construction and use of this design, whether considered as caused by any deemed negligence of the designer or otherwise, and agree to indemnify and hold harmless, the designer, his heirs, successors, and associates, from any loss, liability, damage or cost that may arise relating to the building and use of this design.

Link to Contact Page

Wing’soul. Easiest to Build Wing Sail.

Introduction: Wing’soul. Easiest to Build Wing Sail.

Here's an incredible Instructable for building a wing sail, called the Wing'soul . It's the world's easiest to build wing sail because simplicity overrules complexity. Common components (found at most hardware stores) are chosen over custom boat parts. Flat cut canvas is preferred over curved cut. Easy to sail and safety wins over specialized sail wardrobe.

First, there is no rotating mast requirement. The Wing'soul is best paired to a static freestanding mast. An example is the Laser dinghy, with its plain mast. For a larger boat, a junk rig or the Freedom rig is ideal for conversion. If you want to convert a standard Bermudian rig, you'd have to change the mast. The mast must be round (not have a flat side) and without mid-mast spreaders. Due to the change in the center of effort, probably the new mast will need to move forward (about 3% of the LOA), closer to the bow.

Guess why wing sails were invented decades ago, but never got popular? Because almost all of them were designed with a rotating mast. Nothing kills adoption faster than this costly complication.

Another simplification: no hardware hinge . You'll notice a lot of other wing sails require a pivot or a hinge at the boom to switch the camber around. However, when the Wing'soul tacks, the wing sail (mainsail and jib/jiblets) changes camber automatically. It works exactly like a windsurfing rig.

In fact, the Wing'soul is heavily based on the Aerojunk , a rig invented by Paul McKay back in 2012. The Aerojunk is a junk version of the windsurfing rig; the Wing'soul is a winged version of the Aerojunk.

The sail is cut flat. No broadseaming or darting or rounding to create draught, unlike the cut in a Bermudian mainsail. Assemble the mainsail by seaming together long strips of rectangular sail cloths. The teardrop shape of the small winglet battens gives curvature at the luff. Aft of the luff to the leech, there is enough sail slack to produce camber.

The jib is also cut flat. The jib can be one long flat sail, or broken up to several pieces called jiblets. Jiblets are trapeziodal. The battens arrange the jiblets so there is slack, both horizontally and vertically. This creates camber in both axises.

This Instructable is for a small trial sail, perfect for a sailing dinghy like the Laser. It is also a learning tool, prototype, about how to build a bigger one. Fortunately, this rig scales up easily . A larger version will be bigger and sturdier, but has no additional components. I dream of making a Wing'soul rig for my 50-footer three masted schooner.

A lot of the Wing'soul's characteristics can be based off the Aerojunk and the original junk rig. You should find: the Wing'soul reefs easily , handles very well downwind and beam-reach. On a broad-reach, it is possible to ease sheet past square, and "sail in the lee" for best performance. Like a junk, it's superb in heavy seas , mostly because of how well it reduces sail area, hardly ever flogs , and docile because of its semi-balanced design (the jib's CE partially offsets the main's CE).

What about close-hauled? This point of sail needs further testing. However, the main and jib has plenty of camber for upwind beating. Camber can be anywhere from 6% to 12% . Really, it depends on internal lengths of the battens versus the length of the sail's chord. The slot effect , a key to a Bermudian's strength, is also part of this rig. Even better, the main's luff is a wing, further improving the aerodynamics at the main/jib junction, while reducing mast turbulence. Finally, induced drag (drag from vortex creation) is reduced because the planform may be tapered and rectangular. This is an improvement over triangular Bermudian mainsails. The Bermudian does have an advantage over the Wing'soul: higher aspect ratio for equal sail area. How all theses factors play out in the real world requires more testing.

Finally, this rig will be fairly cheap to build , as nearly all the materials can be sourced from non-marine industries. For example, the mast can be a re-purposed aluminum utility pole, the sail material is outdoor utility canvas, the battens from aluminum tubes. This prototype cost $300 USD in parts. $100 was for the light rip-stop fabric. $100 was for the aluminum tubes, to make the wishbone battens. The rest was $100 for miscellaneous parts.

Please comment if you built this rig and tell me how it performed for you!

The most important tool to have is the drill press, when building the battens. You'll want to create clean, straight 90 degree drills. Also desirable is the ability to drill 15 degrees from normal.

A good sowing machine is important. A "yachty" machine is perfect, but any small home machine will work for a small sail.

- Drill press

- Hand drill & bits

- Hand saw (or jig saw) for aluminum and ply wood

- Measuring tape, pencil, marker

- File, sand paper, rasp

- Rivet gun and pop rivets

- Nails & screws to hold wood temporarily

- Sowing Machine

- Grommet press and grommets

- C-Clamps to hold things down

- For a cruising yacht, use UV resistant fabric such as Sunbrella, Top Gun, or Weathermax. The multiple wishbone battens takes most of the sailing loads, so there is no requirement for Dacron. However, you may use Dacron, plastic tarp, or old sail cloth if you wish. Material selection depends on if the sail is a trial, bluewater, tropical-tolerant, or made-on-the-cheap.

- Plywood for the winglet template

- Round aluminum tubes, 15mm diameter, 1mm thick walls, 2m long, QTY 11

- Square aluminum tubes, 20mm each side, 1.5mm thick walls, cut to 40mm length, QTY 10

- Aluminum flat bars 15mm wide by 2mm thick, 2m long

- Aluminum flat sheets, to make the C-keepers.

- Bolts and Nuts, M6, 60mm long

- Hose clamps

- Rope for rigging the halyard and sheets

- Single block sheaves for rigging the halyard and sheets

- Sticky sided Velcro, 15mm wide, 20m long

Step 1: Learn About the Aerojunk and Junks in General

Before you get started on the Wing'soul, read about its predecessor, the Aerojunk. Big thanks to Paul McKay for inventing the Aerojunk, as the Wing'soul would not be possible without him!

Original Aerojunk Design:

https://www.yumpu.com/en/document/view/38970140/t...

If you join the Junk Rig Association (there's a small membership fee), the 84th newsletter has updated Aerojunk information.

http://www.junkrigassociation.org/

Here's a website to learn about junk rigs in general, and why they make good rigs for cruising yachts.

http://www.kastenmarine.com/junk_rig.htm

Here's an article from Practical Boat Owner, comparing the Split Junk vs. the Bermudian, side-by-side. They concluded the junk is best off-the-wind, and the Bermudian is best on-the-wind. Either rig has its weaknesses and strengths, it depends on which point of sail. The Wing'soul is the best of both worlds. It should sail upwind like a Bermudian, while retaining formidable off wind performance and ease of handling.

https://www.pbo.co.uk/seamanship/bermudan-rig-vs-junk-rig-17481

Step 2: Cut Aluminum Tubes

In this step, you'll make the wishbone battens by cutting tubes to the correct lengths. Don't worry if the battens look complicated, with all its curves. The batten shaping is actually fairly easy to do.

The Aluminum Cuts

Cut the round aluminum tubes (15mm diameter, 1mm thick) to 2m lengths. Even better if the tubes can be bought at those lengths. You'll need QTY 10 of these outer battens to make 5 wishbone battens.

Cut the remaining round aluminum tubes for the removable crossbars. The length is around 320mm, to get a 12% mainsail camber. Shorter crossbars makes the wishbone battens skinnier, and hence less camber. Don't worry about the length too much, it can always be adjusted shorter, later on. Make QTY 5, all of equal lengths.

Then cut the square aluminum tubes (20mm side, 1.5mm thick) to short pieces, at 40mm lengths. Drill a hole through the pieces, big enough to have the round tubes slide through. You'll need a fairly big drill bit, 15mm or 15.5mm diameter. Then rotate the piece 90 degrees and drill a hole meant for a M5 sized bolt. Take a look a the diagram for reference. Make QTY 10.

Assemble Battens Into a Long Legged H

Place two straight, 2m long, round battens side by side on the floor. Slide a square end piece, into each of the battens. Stick the removable crossbar (round, 320mm long) inside the square end piece. Now is a good time to look at the diagram again, to see the end result. What you have arranged looks like a long legged 'H' on the floor.

Before bending the two battens, first secure the removable crossbar to the square end pieces. Use a hand drill and drill a M5 hole at the end of the crossbar, using the hole at the square end piece as a guide/template. Use the same sized drill bit. Once you drill through the ends of the removable crossbar, secure with bolt and nut. Repeat on the other end.

Install hose clamps over the outer battens. Loosely slide the clamps until they are adjacent to the square end pieces.

Now you're ready to bend the outer battens in the next step.

Step 3: Bend to Make Wishbone Battens

Use a measuring tape and mark off the tip of the battens to the location of the crossbar, a distance of 525mm, on both battens. This is shown as points "A" and "B" in the diagram. Once bent, the distance from the tip to the crossbar, will end up as 515mm (roughly).

Slide the crossbar along the battens to the 525mm mark. Lock the crossbar/square end piece, by tightening the hose clamps** on each side. Make sure both battens are equal, so the bends are symmetrical.

With a friend's help, hold down the battens. Then another person can bend the batten tips (points "A" in the diagram gets closer) . The aluminum tubes will spring back a little.

Lock the bend down with bolts & nuts. Use a hand drill to drill holes through the battens and use a long bolt. Another option to a long bolt, is to use a threaded round bar. A third option, what I did, was to use a drill press to drill at 15 degrees offset. Then fitted a small diameter aluminum tube through and rivetted in place.

Now you are finished making the aperture for the jib/jiblets.

Don't worry too much of how long this cross bolt should be (the distance between the "A"s). Its not super critical. Even the distance between "A" and "B" = 525mm is not critical. It is best to start with something, and adjust the battens later.

To make the aperture for the mainsail, the technique is almost the same. The difference is to place a wooden stick about 340mm aft of the crossbar. The diagram shows this as 340mm from point "B". In the diagram, a third (right-most) wooden stick is shown. That's optional.

Make the bend at the tail ends of the battens, with a friend's help. Then lock the tails together with long bolts or threaded round rods and nuts.

Once one wishbone batten is complete, repeat the previous and this step to make the other battens.

----------------------------------------------------

** hose clamps to lock the square end piece is preferred. If you look at the example photo, the square end piece was riveted to the battens, instead of a clamp. This okay for a trial sail, but not okay for a "real" sail. A drill hole, for the rivet, will severely weakening the aluminum battens at this location.

Step 4: Make the NACA0012 Winglets

In the previous steps, you learned how to make the wishbone battens. They are the key to the Wing'soul's simplicity. No rotating mast is needed as the mainsail and jib/jiblets rides on the battens; the battens rotate around the static mast. No articulating hinges are necessary because the outer battens allows the wing sail to tack and create camber.

In this step, make the winglet battens. They create the luff pocket for the mast. The airfoil is based off the NACA0012.

Begin by making a wooden template, shaped to an airfoil. Then mount on another wood board.

Start by downloading the airfoil, NACA0012, and print out the shape.

Try http://www.airfoiltools.com/

Size the print out so that the mast will fit inside the nose of the NACA0012. For example, if the mast has a diameter of 40mm. Scale the print out so a 40mm diameter circle can easily fit inside the nose section. See the diagram; the airfoil encompasses the mast, with some room to give.

Cut the printout with scissors, then apply it to the wood piece.

Draw the outline to the wood plug, cut out the shape with a jigsaw or handsaw. Only 50% of the airfoil shape is used. One could also use 100% of the airfoil, instead.

Mount the male plug on a flat wood board.

Wrap the aluminum flat bar, 15mm wide and 2mm thick. Secure the bar to the wood plug with C-clamps. Use a mallet to wrap and pound the bar into shape.

Rivet together the ends to finish the winglet so it does not pop open.

Repeat this step to make a total of QTY 5 winglet battens.

Finally, add a small piece at the nose of the winglet. This is the flat plate. The plate prevents the mast from jamming the insides of the winglet. Without the plate, reefing the sail becomes very difficult.

C-collars, Make Later

C-collars prevent lifting and capsizing from the wishbone battens. They are attached to the winglets on both sides of the winglets (windward and leeward). You do not need to make C-collars now. The reason because, the placement of the C-collar is unknown. Once the rig is assembled together, then positions can be marked, and the C-collar can be positioned correctly.

Step 5: Make the Riblets

Riblets are shorter versions of the winglets. Winglets are 50% of the NACA0012 airfoil chord. Riblets are only 25% in length.

Riblets prevents the windward side of the luff to collapse under windward pressure. Aim to make two riblets between panels. Riblets billow out the luff, improves luff shape, and prevent the luff from"sticking" to the mast if the sail gets wet.

Modify the wood plug used in the previous step to make the winglets. Cut the wood plug in half. Mount the front nose of the plug back into the wood mount.

Then wrap the aluminum flat bar, using a mallet just like the previous step to make the winglets. Rivet the ends.

A flat plate is NOT needed for the riblets, as this omission does not affect reefing.

Repeat to make the other riblets. Make at least QTY 8.

Step 6: Jib Sail Canvas

The jib is one long piece. Jiblets are several smaller pieces, when combined, works together like one large jib. This step focuses on making jiblets, as this is preferred over making one large jib. Jiblets tack better in light winds, have deflection to improve performance, and easier to make due to the smaller size.

Jiblets are trapezoidal and cut flat. The luff of the jiblet is the nominal distance of one panel. In the diagram, one panel height is 0.89m. So the luff distance of the jiblet is also 890mm. Technically, the eyelets at the luff will attach at a distance of 0.89m. The jiblet is slightly bigger to accommodate the eyelets, plus overlap to allow rolling and stitching for the edges.

Vertical Camber and Deflection

The angle at the luff corners are 7 degrees. Why 7 degrees? It's a good starting angle. It gives enough slack at the leech to create camber vertically. This vertical camber allows the jiblets to deflect out, with respect to the mainsail. The bigger the corner angle, the longer the leech. The longer the leech, the more slack; extra slack begets more deflection.

Most of the sail "lift"** in the rigid two-element America's Cup wing sail, came from deflection. Deflection is the angle between the chord of the first-element wing with respect to the second-element wing chord. The deflection of the jiblet works the same way: it increases the driving force of the sail.

Horizontal Camber

Camber in the horizontal axis happens when there is slack at the foot of the jiblet. The diagram shows a foot distance of 1020mm. The ideal batten would hold the jiblet at 1000mm apart. That means the jiblet has a 2% slack (1020mm is 2% longer than 1000mm), which creates horizontal camber. Why 2%? It creates about 10% of actual camber. But your results may vary.

-------------------

** lift is an aeronautical term, but you know what I mean when applied to a sail on a sailboat.

Step 7: Wing (Main) Sail Canvas

I used the book "A Sailmaker's Apprentice" by Emiliano Marino to help during this step.

The basic outline for the mainsail is this:

Start off with making just one panel of the mainsail. Since one mainsail panel runs horizontally, the raw canvas when delivered will be approximately the same size as the final panel. In this example, the final panel height is 0.89m, or the distance between wishbone battens. So the ideal roll of canvas should be slightly wider than 0.89m. Roll and sew the edges and the final panel height will be 0.89m.

The diagram shows where to apply the Velcro. First apply the Velcro for the winglet batten and the riblet battens. Then hand stitch them to the canvas to secure. Velcro may be too thick to sow with a machine. Some Velcro have bald edges, where a sowing machine may penetrate the thinner backing onto the canvas.

The two vertical strips terminates the trailing edge of the wing portion. Temporarily stick the Velcro there, but do not stitch.

Setup the mast, along with two wishbone battens. Install Velcro to the winglets and riblets. Assemble the one panel of the mainsail to the wishbone battens, winglets and riblets --like a dress rehearsal. Once that is complete, examine the mainsail and make necessary changes, measurements or adjustments.

Mark where to punch a hole, or crossbar aperture, on the mainsail. This aperture is there the removable crossbar will go through both plys of the wingsail. The crossbar and aperture are aft of the mast, to allow room to pivot during tacking. Don't forget to reinforce the aperture, or else the aperture will rip.

Once the mock up is finalized, make the other mainsail panels.

Sew all the horizontal panels together to make one large mainsail.

Add the two long strips of Velcro that run up the sail. This holds the trailing edge of the wing together. Hand stitch or machine sew the Velcro to the canvas.

Phew!! That's a lot of steps to make one mainsail. And we did not cover any the details, like grommets, eyelets, bolt ropes, corner patches etc... Luckily, for a small trial sail, you can skip all that.

----------------------

To tell you the truth, the mainsail for this particular Wing'soul was done in vertical strips, instead of horizontal strips. There are pluses and minus to either case, but not a concern for a small sail. If I were to make a large sail, I'd opt to make the mainsail with horizontal strips, as outlined in this step. Mostly because a completed one-panel mainsail can be hoisted with just two wishbone battens. Then sizing and testing can commence without making the entire mainsail.

Step 8: Put It All Together

Once the mainsail and jiblets are complete, assemble the sails along with the mast and battens.

Install two single blocks at the mast top, to run the halyard. Then raise the mast onto the mast support.

Run the halyard up the mast, through first block, then down to the yard block. Then up again to the second mast top block, and terminate on the second harness on the yard (your top most wishbone batten). The yard is wide, so a harness will balance the battens from tipping.

Slide the top winglet through the mast. Let it sit above the crossbar of your yard.

If winglets and riblets need Velcro, apply them now.

Wrap the mainsail around the top winglet. Secure the leech of the mainsail to the batten end.

Remove the crossbar, by loosening the nuts and bolts. Then re-install the crossbar through the mainsail. Since the crossbar aperture is already there, just slide the crossbar through.

Also install the top jiblet.

Insert the riblets inside the mast, and stick that to the mainsail.

Slowly hoist the yard with the halyard, one panel at a time. Continue adding more wishbone battens, winglets and riblets and jiblets.

After the bottom panel and boom (bottom most wishbone batten) is assembled, your sail rig is completed and hoisted!

Step 9: Final Details

Collars and Stoppers

Once the entire sail is raised, you'll first notice the battens tend to capsize and shift. There are two solutions to remedy these problems:

1. C-collars added to the winglet battens, prevent the wishbone battens from tilting, "capsizing", out of the winglets. Capsizing causes the wishbone battens to not be parallel to each other. The C-collars must not be too restrictive; some play allow the winglets to move around for tacking.

2. A winglet stopper in the middle of the crossbar to prevent the winglet from straying or shifting outside of center. The stopper can be a hose clamp or a pin.

Finally, all the batten ends must be controlled with the sheet line. The preferred method is Chinese junk sheeting.

This features:

1. The ability to set the twist for each batten. This translate to ultimate control of twist from the foot to the head of the sail.

2. The mechanical advantage of running the sheet through multiple pulley blocks; couple this with balanced configuration (the jib's CE partially offsets the main's CE). Therefore, sheeting does not require further assistance. The general rule is, Wing'soul and other junk rigs do not require sheeting winches. The easing and tensioning of the sheet is done solely by hand. Even on my 50 foot heavy steel boat, with 500 sqft (46 m^2) sails, in 20 knots wind, sheeting is done manually without a winch.

Topping Lif t

Topping lift holds the sail up when the halyard is eased, so it does not lay on the deck floor when reefed. A small sail would not need a topping lift. However, a practical larger sail would require one.

An excellent reference book for rigging is "Practical Junk Rig" by Hasler & McLeod.

Step 10: Testing and Final Notes

A big problem with this project was the testing. The sail was built in Romania -my land base when not cruising. This part of Europe has few sailboats. A land sailer, made from off-road skateboard wheels, was built specifically to test this rig.

It was difficult to find the right days to try the sail, as few days were windy. And harder still to find a suitable surface large enough, yet open to the wind.

On the day of the test, one of the wheel axle broke, due to poor welding. With a wheel missing, the rig was ballasted on only one side.

Included is a video made to show how well the Wing'soul reefs. There's the dry reef. Which the sail did excellent on. Then the entire sail was doused with a garden hose to simulate a rain squall. The wet reef was nearly as good as the dry one.

Have fun making the Wing'soul! Would love to hear how it works for you in the comments below!

Participated in the First Time Author Contest

Recommendations

Outdoor Life Contest

Art and Sculpture Contest

Microcontrollers Contest

- Forum Listing

- Marketplace

- Advanced Search

- All Topics Sailing

- General Sailing Discussions

- SailNet is a forum community dedicated to Sailing enthusiasts. Come join the discussion about sailing, modifications, classifieds, troubleshooting, repairs, reviews, maintenance, and more!

Rotating wing masts

- Add to quote

Lately I’ve been reading a lot about rotating, free-standing, carbon fiber, wing masts. By all accounts they’re much more efficient than the usual arrangement. If this is true why don’t we see more of them? I understand the problems that it would create for racing, but not everyone cares about racing. I also understand that they’d be more expensive, but carbon fiber spars now proliferate all sailing sub-genres. I also understand taht it may not be practical to redesign an existing boat’s rig, but why don’t we see these on more new designs? I, for one, am always trying to find ways to make my boat more efficient and faster. And I feel like this is a trend among all sailors, even devout cruisers. Why is such an obvious leap forward in sailboat evolution being ignored?

Pretty sure it isn't just expensive, its very very expensive.

I assume that you indeed mean wing *mast* and not the wing sails that proved so devastating in the last America's Cup. Wing Masts are like many ideas which really well work in narrow applications. Wing masts offer very small gains in performance but with a high degree of complexity. Wing masts work very well on high efficiency, low drag applications. In that mode they offer an efficiency that can actually be used by the vessel. They are great on high speed vessels like ice boats and racing multi-hulls, because these crafr have apparent wind that is almost always from forward of abeam. But that small gain in efficiency comes at a price; a very big price in terms of practicality when applied to more normal vessels. For example, wing masts need to be free to rotate, but with their angle of attack controllable, so that they can offer the proper angle of attack for the wind direction. That means that the crew needs to be able to adjust not just the mainsheet, but the mast angle of attack. Around here there are folks who argue against the advantages of a fractional rig by suggesting that it is too hard for the average sailor to learn to use a backstay adjuster. Visualize the average sailor learning to properly adjust the angle of attack of the mast (remembering that a wing mast is only more efficient when the angle of attack is correct, but greatly increases drag when it is improperly adjusted). Allowing free rotation requires a single axis of attachment for the shrouds or else a cantilevered connection. If a vessel is very beamy then the vertical staying of the mast can be isolated from the bending sideloads on the spar itself, which is part of the reason that wing masts work really well on multihulls or iceboats. But on a monohull this makes staying very tricky without something like the side struts seen on open class boats. If the choice is to use a cantilevered connection, there needs to be adequate fore and aft as well as side to side bracing of the bearing points for the embeded portion of the mast, and either an above deck set of bearings or else a set of bearings at the heel or the mast and at the deck, with the deck bearings being water tight. Proper support of the deck mounted bearing would in all probability require fore and aft as well as lateral bulkheads or knees occupying much of the interior in the area of the mast. Wing masts have a lot of 'sail area' in the mast alone, at times more sail area than the boat can safely use and so for a cruising boat, which encounters winds of a variety of forces and directions, this inability to 'reef' the sail area of the mast can be a dangerous liability. This can be a significant problem at anchor or tied up at a dock. In the past, vessels with wing masts were generally daysailors and boats which are small enough that the mast could be unstepped at night. There have been experiemental boats with wing masts which have allowed their masts to feather, but that can mean a lot of noise and a lot of vibration. Then there is the weight versus cost issue. While a wing mast can be lighter than a conventional stayed spar, for the most part, they tend to be a heavier rig, due to the isolation of the side support from the structure resisting the bending of the spar. This can be worked around by using exotic materials but of course this has serious monetary consequences. And even if these complications could be effectively addressed, the offshore sailing community tends to be pretty conservative. Here we are nearly fifty years after aluminum spars with modern engineering became the norm, and yet the cruising community still argues that deck stepped masts are somehow less safe. So if you can visualize that, now try visualize trying to convince them that a mast supported on a ball-joint with a single shroud lead to a strut on either side makes sense. I don't see that happening any time soon. In terms of retrofitting a wing mast to a conventional monohull, there would be little to no real gains in performance, but even if there were measurable gains in performance, the costs and complication would be prohibitive, especially since there are a wide range of less expensive alternatives which would be more effective in improving performance. Jeff

Red, by 'wing' mast do you mean the aerorig? Resultados da Pesquisa de imagens do Google para http://upload.wikimedia.org/wikipedia/commons/a/aa/Paratii_2.jpg

Jeff, thanks for the excellent (as always) explanation. I think all of your points are very valid and make perfect sense. I'd be interested to hear your thoughts about this design that I just stumbled upon while researching wing masts. To my very untrained eye it looks like it would be a very efficient rig, but based on what you've said above it would be more trouble than it's worth, and for that hull it wouldn't add much in the way of preformance. Globetrotter 45 Copa, I'm referring to a mast with a cross section similar to a wing. Not a wing sail or any other rig anomalies.

- Low hull-speed due to a short waterline length relative to length overall,

- Displacement hull form,

- Comparatively low stability, and

One of the worlds main developers of Wing masts for yachts is I believe based near me in Inverness,Scotland and there are several examples to be seen locally-one in particular fitted to a big catermaran(suspect this might have been the test bed) Can be very efficient in large scale commercial applications.

Wow, Jeff, quite an explanation! I pulled the motor out of my boat and glassed over the aperture, thus I'm completely at the mercy of wind and tide. I've spent many an hour on light air days either drifting or swinging on the hook contemplating ways to improve my rig. I have concluded precisely what you've said above, that it's just not worth all the trouble and expense for such marginal gains in performance. I bought my Triton because it was the best boat that I could afford at the time. And since I've had her I've identified many traits in her that I do not wish to have on my next boat. If I get any wild hairs to make major rig modifications I will wait to do it on an appropriate hull. I was curious about wing masts because they seem like they would offer many advantages over traditional rigs when married with appropriate hulls. I wanted to know that if this was indeed that case, why we didn't see more of them. Jeff, you've more than answered my question and I really appreciate your insightful responses.

You are very welcome.... I tip my hat to you sailing a Triton without an engine. I should say that I too enjoy that unique aethetic to sailing an engineless boat, and admire the skill required to do so with a boat like the Triton. (I did the same thing with a Folkboat back in the 1970's) You learn all kinds of tricks and you really become one with the boat (or else spend a lot time in trouble). Jeff

Thanks Jeff. I totally agree with you about becoming one with the boat. I used to work as a sailing instructor for Outward Bound’s Hurricane Island sailing school where we did a lot of engineless sailing. It was always amazing to watch inner city kids who’d never even seen an ocean before deftly handle their vessel after just a few weeks. It was also interesting to see them form an affinity for a craft that dealt out much more pain than pleasure. I thought a Triton would sail like a hotrod compared to the schooners and dumpy OB boats I grew up sailing. Man, have I been disappointed. My next boat is going to be quite different; light air performance is now my number one criteria (hence my initial posting). I used to moor in Woods Hole and the current there could best my little boat 50% of the time. Now I’m out of NC’s Cape Fear river and I spend about 40% of my time getting skunked.

A little advice from someone who has sailed mostly offshore for over 50-years now, if you spend much time sailing offshore, anything that moves, pivots or goes up and down, even if you take good care of it, will eventually become a problem. The simpler the systems on your boat are, the easier it is to care for, the less likely it is to fail and the easier it to repair when the time comes - and it will.

I totally agree. But I think that in some ways a rotating mast would be simpler. Yes, the joint on which it was mounted could become a problem. However, you wouldn't have all the standing rigging creating problems or chainplate issues.

I should add that I’m not a proponent of wing masts, I’m just playing devil’s advocate. I also know that there is some standing rigging associated with this configuration, just not as much. (or so I've read...)

- ?

- 176K members

Top Contributors this Month

- Yachting World

- Digital Edition

How wingsail technology could revolutionise the shipping industry

- October 26, 2022

Do superyacht designers have the answers to the future of efficient sailing and shipping? Mark Chisnell reports on why variants of wingsail technology could be coming to an ocean near you

On a summer weekend there’s always a bustle of activity on the foreshore at Hamble-le-Rice, on England’s south coast. The whirr of electric air compressors has been the soundtrack to the rise and rise of the inflatable paddleboard . And it may be about to initiate another transformation, simplifying sailing to the point where it returns to its birthplace; commercial shipping.

Matt Sheahan reviewed the Inflatable Wing Sail (IWS) for Yachting World more than three years ago and was impressed by the invention of Edouard Kessi and Laurent de Kalbermatten. Based on an unstayed, telescopic mast, the IWS inflates via an integrated air compressor to a surprisingly low pressure, just two millibars.

It creates a soft, symmetric wingsail with many of the efficiency advantages of a hard wingsail (amply demonstrated in America’s Cup and SailGP racing) but none of the problems – it’s very simple to raise and lower, and just disappears down to the deck when you don’t need it. Matt predicted that the much-simplified handling could mean a significant future for the IWS in superyachts and commercial shipping.

The simple to handle Inflatable Wing Sail (IWS) we featured in 2019

Simplifying the way that sailboat rigs work is far from a new idea. The IWS follows in the wake of many of these initiatives with its unstayed mast, an idea that has its origins in the Chinese junk rig.

Gary Hoyt’s Freedom Yachts utilised this approach in the mid-1970s. Meanwhile in the 1980s, a building beside the very same River Hamble produced the AeroRig, a free-standing mast with a rotating boom on which both headsail and mainsail were set. The forces were easily balanced and controlled by the mainsheet alone.

A descendant of the AeroRig is the Dynarig, developed by Dykstra Naval Architects and built by Magma Structures in the UK for two spectacular superyachts, the Maltese Falcon and Black Pearl . A recent partnership agreement with Southern Spars means that the Dynarig will now be developed with the support of one of the marine world’s most sophisticated technology providers. The rig is targeted at the people who want to keep it simple, and this can include superyacht owners interested in reducing crew numbers and handling issues.

Dykstra has a Wind Assisted Shipping Project (WASP) in process, a multipurpose cargo ship which uses the Dynarig masts as cranes, and is working with Veer on the world’s first emissions free cargo fleet. The Dutch design house, responsible for some of the most iconic superyacht and J Class projects, also tells us that it is currently working on a couple of new classified Dynarig superyacht projects.

This is where most of the momentum is headed with these new technology rigs in the superyacht world. VPLP is perhaps the world’s most successful yacht design groups since Marc Van Peteghem and Vincent Lauriot Prévost set up their business in 1983.

They’ve won the Vendée Globe , the Jules Verne , the Route du Rhum , and in 2010 the America’s Cup with the huge wingsail on BMW Oracle. “Marc [Van Peteghem] saw the potential of that highly efficient automatable wingsail,” explained Simon Watin, president of their maritime division.

“He’s been at the forefront since that period, really pushing in parallel the maritime transportation and the yachting together,” continued Watin. VPLP started drawing the concept in 2016 and built the first Oceanwing to fit on a small trimaran. It’s an automated wingsail that hoists on an unstayed mast – similar to the IWS but using battens to create the wing’s shape, rather than inflation. It’s a two-element rig though, allowing for a more efficient foil and higher performance. VPLP built two 32m2 Oceanwings for Energy Observer , a former racing catamaran now circumnavigating as a technology platform. They also started to pitch eye-catching concept designs into the superyacht community.

“The people we are looking to convince are people that would normally go for a pure motor yacht,” explained Watin, “and who would not be so much interested in the sailing aspect itself.” Watin pointed to the gains in fuel economy, range, comfort and autonomy. The Seaffinity is a streamlined, concept trimaran from VPLP, “with a large main hull and two smaller floats featuring two Oceanwings, one behind the other,” explained Watin. “And this is really an illustration of a new superyacht that could have been a pure motor yacht, but actually benefits from the Oceanwing.”

Dykstra’s Dynarig projects, made famous by Maltese Falcon and Black Pearl (pictured), are being adapted for shipping

Superyacht concepts

Another VPLP/Ayro collaboration has resulted in the radical Nemesis One superyacht concept, a 101m/332ft foiling catamaran capable of 50-knot speeds. The fully automated, push-button craft uses a modified Oceanwings wingsail which can furl and reef and automatically adjusts its angle of attack. There’s no question that this and the Seaffinity are striking vessels, and that the technology could make a significant dent in the operating carbon footprint of yachts that might otherwise have been engine-only.

The first large scale Oceanwing will be a commercial shipping project. The step came when VPLP and the shipping company Alizé successfully bid for Ariane Espace’s tender for a new concept ship that could carry parts of the Ariane 6 rocket from European ports to French Guiana. Once it had the contract, VPLP created Ayro as a separate business to develop the cargo ship Canopée. She is scheduled to launch in late 2022, at 121m long, and will be powered by four 363m² Oceanwings set on 36m masts. VPLP thinks the wingsails will reduce fuel consumption by 15% without compromising speed.

“The technical concept is aerodynamic efficiency with the solid sail with two elements: so reaching maximum lift coefficient. Automation; so no lines, no unnecessary human intervention for trimming, adjusting, hoisting. And much less impact on the deck plan, which is quite major, especially for a superyacht,” said Watin.

The WASP uses its masts as cranes to unload cargo

The difference in the physical and mechanical realisation of the Oceanwing for superyacht and commercial shipping markets is interesting. The version for merchant ships will stick to industrial suppliers as far as possible – electric actuators that would normally mobilise cranes, for instance. The wing will use a reinforced PVC fabric skin, the type of material that would make a truck tarpaulin.

The masts will remain in place in normal use, and the fabric wings will raise and lower on cables powered by electric rams, so the sail area can easily be reduced. A tilting mechanism will allow the mast height to be reduced for ports and bridges.

Unsurprisingly, the superyacht version will be a lot more sophisticated, but is still based on the same self-standing mast and 360° rotation of the sails. “We would use higher technology material, lighter fabrics as well… and for the yachts, we have to be more cautious about the weight of the installation itself, because the sail area is going to be quite a bit larger in comparison to the boat. And obviously, the design is going to be important so we will package all the actuators in a much nicer way – you don’t want a ram sticking out.”

The 48m VPLP design Evidence uses automated and stowable wing sails

Bold initiatives

Ayro is now responsible for all the design and engineering on the Oceanwing, with its own 35-strong design office, but VPLP remains involved. “Ayro has successfully raised quite a bit of funding to sustain its growth,” Watin told me.

It was 2019 when Matt Sheahan made his prediction for the future of the IWS in his Yachting World review, and three years later it appears that the commercial shipping development is also well ahead of the superyacht market.

The WISAMO system is an initiative from Michelin, with two-time Vendée Globe winner Michel Desjoyeaux associated with the project and testing. It’s the same concept as IWS, an inflated wingsail, set on an unstayed telescopic mast.

“When I discovered that system, I thought it has checked a lot of boxes compared to other systems,” said Desjoyeaux. “It has a plug and play system which is very easy to install and use, whether it is for a refit, meaning an addition to an existing boat, or for a newly built ship; you lower the mast into the boat, plug it in and off you go. Once you are out of the harbour, you push a button and the machine does everything. It unfurls the wingsail and automatically chooses the correct setting for cargo ships. This is crucial because there aren’t many crewmembers on the bridge, and they don’t necessarily know much about sailboats. They need a system that operates autonomously.”

VPLP Oceanwing projects on Energy Observer

At the beginning of 2022 Michelin announced a partnership deal with Compagnie Maritime Nantaise to test the WISAMO. The system will be fitted to one of their roll-on roll off vessels travelling between Bilbao in Spain and Poole in the UK. The plan is to have the ship in service by the end of this year. Meanwhile, tests with Michel Desjoyeaux’s own boat continued through last winter in the Bay of Biscay.

Michelin are claiming the system could save up to 20% on fuel costs. It’s in the same ballpark as the Oceanwing, and while it sounds good – particularly at today’s fuel prices – it’s actually only half of what the shipping industry needs to achieve by the end of the decade.

Reducing emissions

The shipping industry pumps out a lot of carbon dioxide – the most recent (2012) estimates being that shipping is responsible for 2.2% of global emissions. The International Maritime Organisation, an agency of the United Nations, has published a strategy for reducing carbon. Global shipping must achieve an average 40% reduction by 2030, increasing to 50% by 2050. The European Union is acting to give these targets legal force, and the first deadline is just eight years away. The task is immense, and the clock is ticking. That’s why the money and energy pushing these new sailing technologies forward is coming from commercial shipping.

Radical superyacht concepts such as Seaffinity feature Oceanwing wingsails from VPLP

One thing that’s been learned in the 150 years since sail last dominated the world’s oceans is that changing the world’s merchant shipping fleet takes time. In 1866, the year of the Great Tea Race, an auxiliary steamer left China eight days after the clipper ships and it arrived in London 15 days ahead of them. Steamships already had a significant speed advantage, but it was more than another 80 years before the last sailing ship ceased trading. This is the problem for the shipping industry; ships are built to last. The world once again needs to restock the entire global merchant fleet with a new technology, but this time there’s a deadline.

The same pressure is unlikely to be felt in the superyacht market for a while, and perhaps it never will. Still, once these new technologies have been developed and proven in the highly competitive shipping industry, it seems likely they’ll start to migrate to superyachts.

No easy options